INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 21 of 68

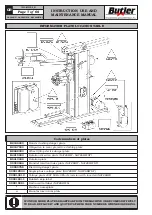

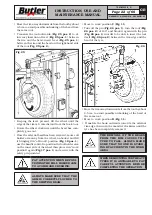

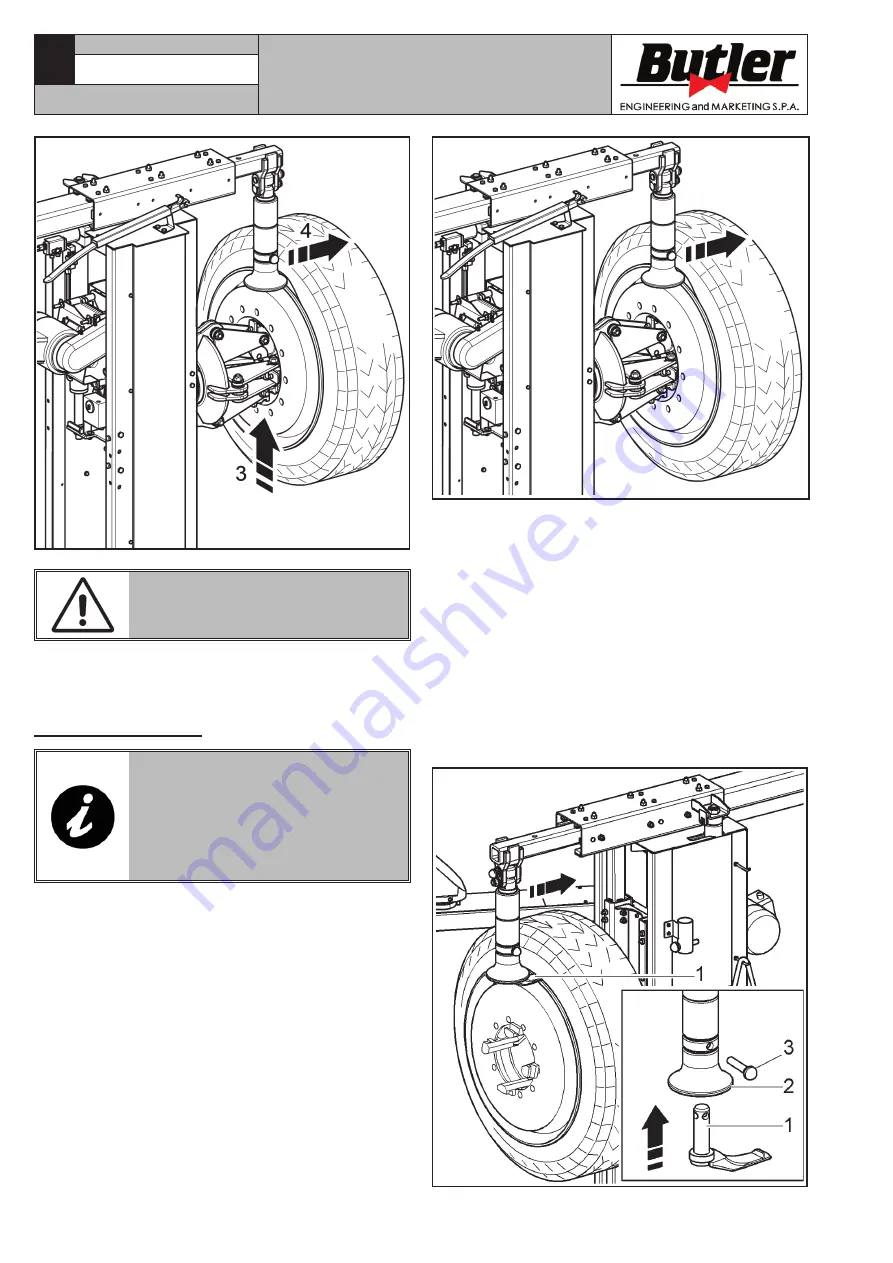

Fig. 23

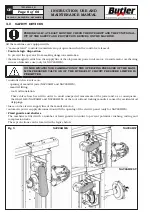

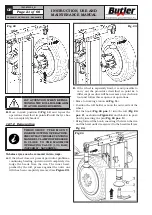

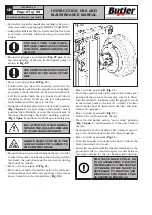

B.

If the wheel is especially hard, it is not possible to

carry out the procedure described in point

A

. A

different procedure will be necessary: use the hook

tool and follow this sequence of operations:

• Move to working station

A

(

Fig. 11

).

• Position the roll holder arm on the outer side of the

wheel.

• Put the hook (

Fig. 24 pos. 1

) into the roll (

Fig. 24

pos. 2

), as shown in

Figure 24

, and block it in posi-

tion by inserting the pin (

Fig. 24 pos. 3

).

• Bring forward the hook, inserting it between the rim

and the bead until it is secured to the bead itself (see

Fig. 24

).

Fig. 24

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

Fig. 22

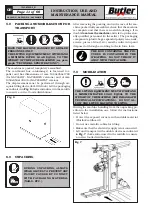

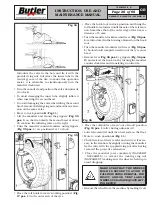

PAY ATTENTION WHEN REPOSI-

TIONING THE ROLL HOLDER ARM

TO AVOID HAND CRUSHING.

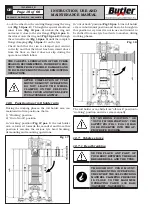

H.

Move to work position

C

(

Fig. 11

) and repeat the

operations described in points

F

until the tyre has

been completely beaded.

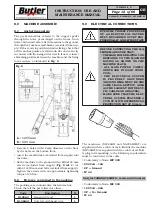

12.7.2 Demounting

THROUGHOUT TYRE MOUNT-

ING/DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CENTRING

MANDREL CLAMPING PRESSURE

IS CLOSE TO THE MAXIMUM

OPERATING VALUE (130 BAR)

(NAV26HW - NAV26HW.S).

Tubeless tyres can be removed in two ways:

A.

If the wheel does not present particular problems,

continuing beading operation will completely dis-

lodge the beads from the rim. The inner bead,

pushed by the roll, presses against the outer one

till it has been completely removed (see

Figure 23

).