INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 23 of 68

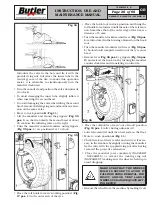

• Move to work position

B

(

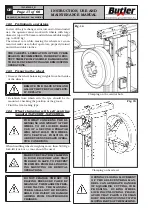

Fig. 11

).

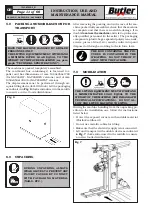

• Lower the mandrel completely. Roll the tyre on the

floor and hook it to clamp (

Fig. 28 pos. 1

)

.

• Lift the mandrel with the tyre hooked and turn it

clockwise by about 15-20 cm; the tyre will position

itself sideways with respect to the rim (see

Fig. 28

).

Fig. 28

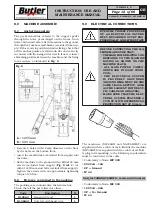

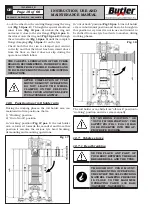

• Position beading roll (

Fig. 29 pos. 2

) so that it is at

approximately 1.5 cm (½”) from the edge of the rim.

Fitting clamp (

Fig. 29 pos. 1

) is at 1 o’clock. Turn

the mandrel clockwise until bringing the grippers

to the closest point to the beading roll (11 o'clock).

Fig. 29

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

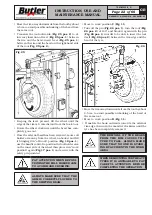

12.7.3 Mounting

THROUGHOUT TYRE MOUNT-

ING/DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CENTRING

MANDREL CLAMPING PRESSURE

IS CLOSE TO THE MAXIMUM

OPERATING VALUE (130 BAR)

(NAV26HW - NAV26HW.S).

Tubeless tyre fitting is normally done with the roll tool;

if the wheel is especially hard to fit, use the hook tool.

With bead breaker roll

Proceed as follows:

• Secure the rim to the mandrel according to the proce-

dure described in paragraph “WHEEL CLAMPING”.

• Adequately lubricate the tyre beads and the rim bead

seat with a suitable lubricant using the provided

brush.

USE ONLY TYRE LUBRICANTS.

SUITABLE LUBRICANTS CONTAIN

NO WATER, HYDROCARBONS, OR

SILICON.

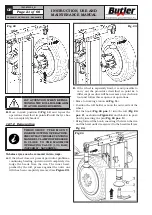

• Mount the grippers (on demand) (

Fig. 27 pos. 1

) on

the external edge of the rim in the highest point as

shown in

Fig. 27

.

Fig. 27

THE GRIPPERS MUST BE TIGHTLY

SECURED TO THE EDGE OF THE

RIM.