Page 20 of 38

GB

INSTRUCTION, USE AND

MAINTENANCE MANUAL

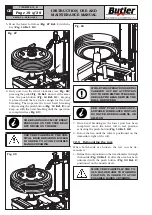

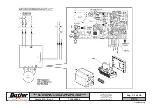

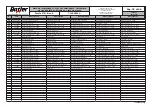

Fig. 30

Fig. 31

1

2

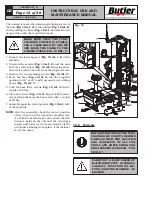

2. Press the pedal (

Fig. 15 Ref. A

) to rotate the whe-

el clockwise until the valve stem reaches “hour 1”

position (

Fig. 31 Ref. 1

).

3. Position the tool (

Fig. 31 Ref. 2

) just next the rim

edge using the provided control (

Fig. 14 Ref. A

)

(tool descent) (see

Fig. 32

). While this phase is

being carried out, stay just next to a zone in the tyre

where bead breaking has been effectuated.

USE VERY CAREFULLY THE TOOL

HOLDER ARM IN ORDER TO AVOID

POSSIBLE HANDS CRUSHING.

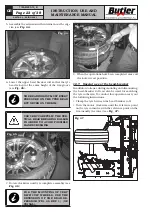

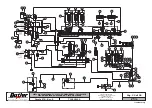

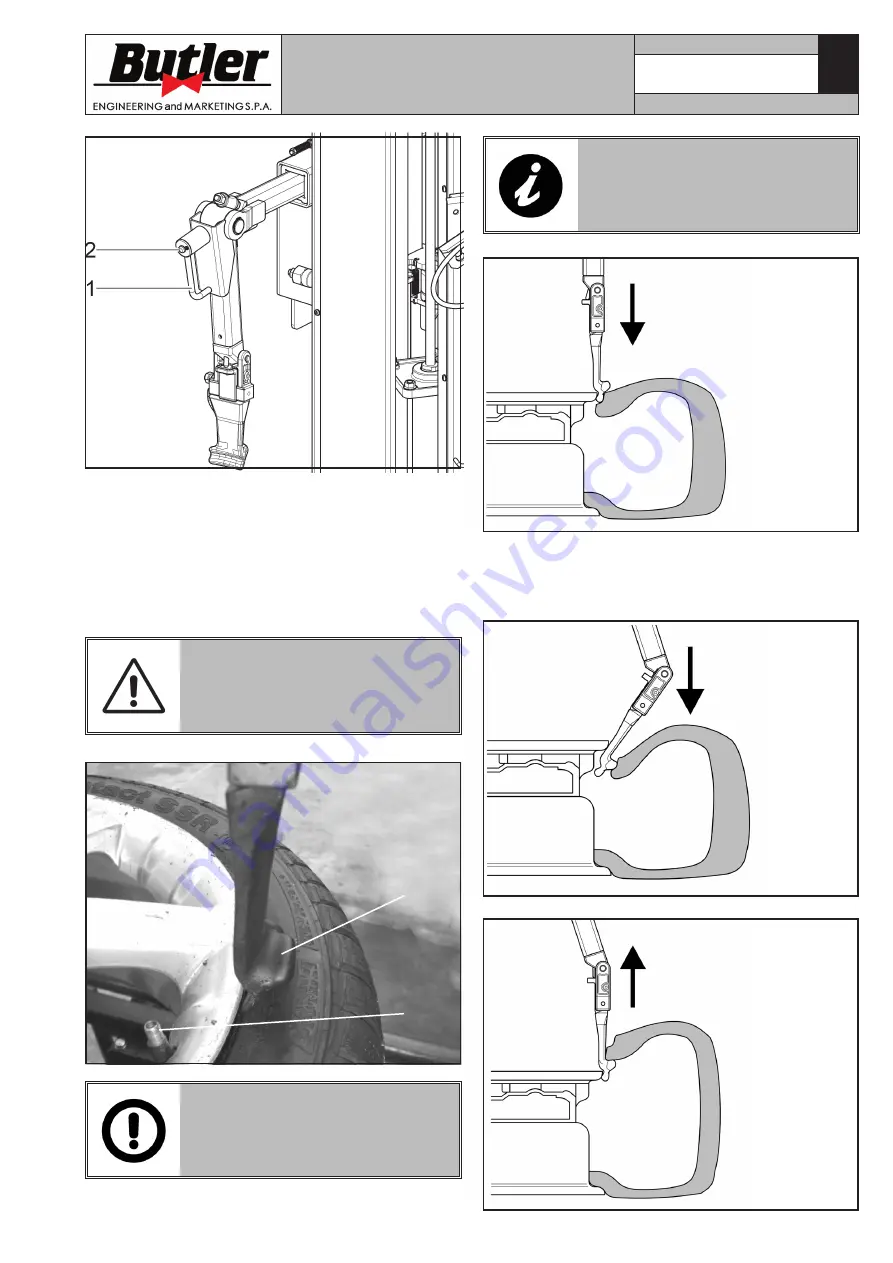

Fig. 34

Fig. 33

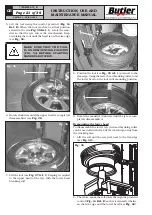

Fig. 32

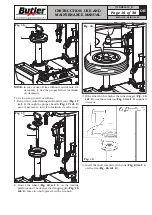

4. Move forward the tool so that it penetrates between

rim and tyre (see

Fig. 33

). While this operation is

being effectuated, the tool rotates around the rim

edge until it hooks the tyre bead (see

Fig. 34

).

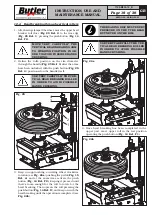

WHILE THIS OPERATION IS BEING

CARRIED OUT PAY ATTENTION

NOT TO DEFORM THE TYRE SIDE.

GREASE THE BEAD BEFORE THE

ROLL RE-ENTERS.

USE ONLY TYRE LUBRICANTS.

SUITABLE LUBRICANTS CONTAIN

NO WATER, HYDROCARBONS, OR

SILICON.

SEIDO.30 - SEIDO.30FI

7105-M005-10_B