20

• To change the gas cylinder in a amply ventilated area, away from any ignition source (candle, cigarettes,

other flame producing appliances, ...).

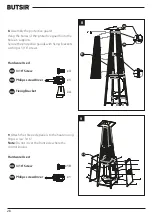

• To check that the regulator seal is correctly fitted and able to fulfill its function showed as photo right.

• To not obstruct the ventilation holes of the cylinder housing.

• To close the gas supply at the valve of the gas cylinder or the regulator after use;

• In the event of gas leakage, the appliance shall not be used or if alight, the gas supply shall be shut off

and the appliance shall be investigated and rectified before it is used again.

• To check the hose at least once per month, each time the cylinder is changed, or each time before long

time no use.

• If it shows signs of cracking, splitting or other deterioration it shall be exchanged for new hose of the

same length and of the equivalent quality.

• The use of this appliance in enclosed areas can be dangerous and is PROHIBITED.

• Read the instructions before using this appliance. The appliance must be installed in accordance with the

instructions and local regulations.

• For connection of hose and regulator, and connection of regulator and hose, please refer to photo

showed above.

HEATER STAND AND LOCATION

●

The heater is primarily for outdoor use only. Always ensure that ade-

quate fresh air ventilation is provided.

●

Always maintain proper clearance to non protected combustible

materials i.e. top 100 cm and sides 100 cm minimum.

●

Heater must be placed on level firm ground.

●

Never operate heater in an explosive atmosphere like in areas where

gasoline or other flammable liquids or vapors are stored.

●

To protect heater from strong wind, anchor the base securely to the

ground with screws.

GAS REQUIREMENTS

●

Use propane, butane or their mixtures gas only.

We strongly recommend the use of propane

, since

there is more bass, suitable for appliances freezing point outdoors.

●

The pressure regulator and hose assembly to be used must conform to local standard codes.

●

The installation must conform to local codes, or in the absence of local codes, with the standard for the

storage and handling of liquid petroleum gases.

●

A dented, rusted or damaged tank may be hazardous and should be checked by your tank supplier.

Never use a tank with a damaged valve connection.

●

The tank must be arranged to provide for vapor withdrawal from the operating cylinder.

●

Never connect an unregulated tank to the heater.

LEAKAGE TEST

Gas connections on the heater are leak tested at the factory prior to shipment. A complete gas tightness

check must be performed at the installation site due to possible mishandling in shipment or excessive

pressure being applied to the heater.

●

Make a soap solution of one part liquid detergent and one part water. The soap solution can be ap-

plied with a spray bottle, brush or rag. Soap bubbles will appear in case of a leak.

CEILING

W

A

L

L

100 cm

100 cm

lgniter

2270 mm

900 mm

650 mm

730 mm

A

B

C

D

E

F

G

H

L

K

J

I

M

N