21

●

The heater must be checked with a full cylinder.

●

Make sure the safety control valve is in the OFF position.

●

Turn the gas supply ON.

●

In case of a leak, turn off the gas supply. Tighten any leaking fittings, then turn the gas supply on and

recheck.

●

Never leak test while smoking.

OPERATION AND STORAGE

TO TURN ON THE HEATER

1. Turn on the valve on the gas supply cylinder completely.

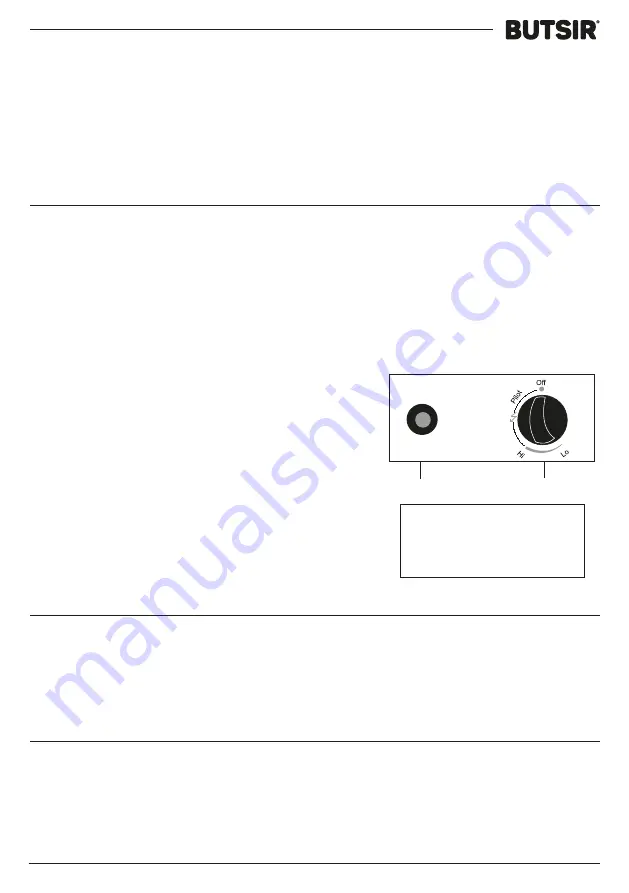

2. Press and turn the variable control knob to PILOT position (counter-clockwise 90º).

3. Press down the variable control knob and hold for 30 seconds. While holding down the variable con-

trol knob, press the igniter button several times until the pilot flame lights. Release the variable control

knob after the pilot flame lights.

Note:

If a new tank has just been connected, please allow at least one minute for the air in the gas

pipeline to purge out through the pilot hole. When lighting the pilot flame make sure that the var-

iable control knob is continuously pressed down while

pressing the igniter button. Variable control knob can be

released after the pilot flame lights. If the pilot flame does

not light or it goes out, repeat step 3.

4. After the pilot flame lights, turn the variable control knob

to maximum position and leave it there for 5 minutes or

more before turning the knob to desired temperature

position.

Warning:

check that no broken on the glass is found before

operation.

TO TURN OFF THE HEATER

1. Turn the variable control knob to PILOT position.

2. Press and turn the variable control knob to OFF position.

3. Turn off the valve on the gas supply cylinder completely.

STORAGE

1. Always close the gas valve of the gas cylinder after use or in case of a disturbance.

2. Remove the pressure regulator and the hose.

3. Check the tighness of the gas valve and for damage. If you suspect a damage, have it changed by your

gas dealer.

4. Never store liquid gas cylinder in a sub-terrain, or at places without adequate air ventilation.

CLEANING AND CARE

●

Wipe off powder coated surfaces with soft, moist rag. Do not clean heater with cleaners that are com-

bustible or corrosive.

●

Remove debris from the burner to keep it clean and safe for use.

●

Cover the burner unit with the optional protective cover when the heater is not in use.

CEILING

W

A

L

L

100 cm

100 cm

lgniter

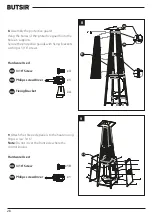

2270 mm

900 mm

650 mm

730 mm

A

B

C

D

E

F

G

H

L

K

J

I

M

N

Ignition

Control button

Off: Off

Max: maximum temperature

Min: minimum temperature