www.buyersproducts.com

Phone (440) 974-8888

Fax 800-841-8003

1

Installation Instructions

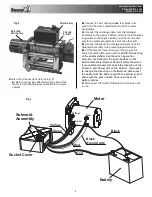

5579500 & 5571200

Electric Winches

WARNING

To prevent serious injury, read and understand all warnings

and instructions before use.

—continued inside

UNPACKING

When unpacking, check to make sure all parts are

included. Refer to Assembly Drawings and Parts Lists.

If any part is missing or broken, please call your local

distributor where you bought the winch from as soon as

possible.

SAFETY WARNINGS & PRECAUTIONS

When using this winch, safety precautions should

always be followed to reduce the risk of personal injury

and damage to the winch.

LEARN TO USE THIS WINCH:

After winch has been installed, take some time and

practice using it so you will be familiar with ALL

OPERATIONS. Periodically check the winch installation to

ensure that all bolts are tight. To ensure proper operation,

carefully inspect for any damaged parts before operating

the winch. Any damage part should be properly repaired

or replaced by identical parts by a qualified technician.

KEEP WINCHING AREA CLEAR:

Do not allow people to remain in the area during winching

operations. Do not step over a taut wire rope or allow

anyone else to do so. Due to the possibility of a cable

breaking,direct all persons to stand clear of any possible

pathways. A snapped cable could cause winch failure,

injury or death. Keep proper footing and balance at all

times. Do not reach over or across the winch and/or wire

rope while the winch is in operation.

INSPECT WIRE ROPE & EQUIPMENT FREQUENTLY:

The wire rope should be inspected for damages that can

reduce its breaking strength. A frayed rope with broken

strands should be replaced immediately. Always replace

the rope with part number 3025776.

WORKING AREA CONDITIONS:

Keep the working area well lit. Do not use this winch in

the presence of flammable gases or liquids.

KEEP CHILDREN AWAY:

Keep children away from working area, Never let children

operate the winch.

USE LEATHER GLOVES:

When handling or rewinding wire rope, always use hand

protection to eliminate the possibility of cuts caused by

burrs or broken strands.

DRUM ROPE:

Always make sure that there are at least 5 complete turns

of rope left on the drum before winching.

KEEP HANDS AND FINGERS CLEAR OF WIRE ROPE

AND HOOK WHEN OPERATING WINCH:

Never put your finger through the hook when reeling in

the last few feet. If your finger gets trapped in the hook

or rope, you could lose it. Never guide a wire rope under

tension onto the drum with your hand.

NEVER HOOK THE ROPE BACK ONTO ITSELF:

Hooking the rope back onto itself creates an

unacceptable strain, breaking individual strands, which in

turn weakens the entire wire rope.

KEEP PULLING DURATIONS AS SHORT AS

POSSIBLE:

The winch is designed for intermittent use and cannot be

used in constant duty applications. Do not pull more than

one minute at or near rated load. If the motor becomes

too hot to touch, stop and let it cool off for a few minutes.

If the motor stalls, cut off the power immediately.

DO NOT OVERLOAD:

Always use this winch at its rated capacity for your safety

and for better performance. Do not use inappropriate

attachments in an attempt to exceed its rated capacity.

AVOID CONTINUOUS PULLS FROM EXTREME

ANGLES:

This will cause the rope to pile up at one end of the drum.

When feasible, get the rope as straight as possible to the

direction of the object.