www.buyersproducts.com

Phone (440) 974-8888

Fax 800-841-8003

4

G.

Disengage the clutch by turning the Clutch Handle

to the Disengaged position.(See Fig.4).

H.

Pull the Cable through the Fairlead and connect the

Hook and Safety Pin.

NOTE: The use of at least a 650

CCA battery is recommended.

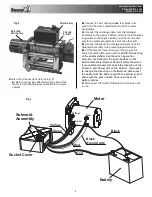

CLOCKING INSTRUCTIONS (fig. 5)

The winch gear housing can be clocked in 8 different

positions. This enables the user to locate the clutch

handle at one of 8 equally spaced points (0, 45, 90, etc.).

The winch is preset at 0.

DISENGAGED POSITION

ENGAGED POSITION

CLOCKING POSITIONS: 0° and 60°

Fig. 4

1.

Remove (2) M8x25 Tie Bar screws that attach the Gear

Housing Assembly to the Rope Drum.

2.

Separate the Gear Housing Assembly w/clutch handle

from the Tie Bars.

3.

Remove (8) M4x12 End Bearing screws.

4.

Separate the End Bearing from the Gear Ring

5.

Reposition End Bearing on the Gear Ring at desired

angle (clocked position).

6.

Replace (8) M4x12 End Bearing screws. Torque to 2

ft-lb.

7.

Align Drive Shaft, Drum Gear, and Tie Bars with Gear

Housing Assembly and reconnect.

8.

Replace (2) M8x25 Tie Bar screws. Torque to 18 ft-lb.

WINCHING OPERATION

1.

Disengage the clutch by moving the Clutch Handle to

the DISENGAGED position.

2.

Grab the Cable Assembly hook with Hand Strap and

pull the cable to the desired length, then attach to item

being pulled.

CAUTION

Always leave at least 5 turns of cable on the drum. Review

winch safety warnings and precautions on pages 1 and 2

before continuing.

3.

Re-engage the clutch by moving the Clutch Handle to

the ENGAGED position.

4.

Lift the Connector Cover on Solenoid Assy. exposing

the electrical switch connector.

WITH WIRED REMOTE CONTROL (fig. 6)

Fig. 5

Fig. 6

1.

While standing aside of the tow path, push the button

on Remote Control forward and backward (Fig. 7 and Fig.

8) to check winch running directions. Wait until the motor

stops before reversing directions.