Save these instructions.

For your safety, read and

understand the information contained within. The owner and

operator shall have an understanding of this product and safe

operating procedures before attempting to use this product.

Make certain that the operator thoroughly understands the

inherent dangers associated with the use and misuse of the

product. If any doubt exists as to the safe and proper use of

this product as outlined in this factory authorized manual,

remove from service immediately.

Inspect before each use.

Do not use if broken, bent,

cracked or otherwise damaged parts are noted. If any

component of this product has been or suspected to have

been subjected to a shock load (a load dropped suddenly,

unexpectedly upon it), discontinue use until checked out by

a BVA Hydraulics authorized service center. Owners and

operators of this equipment shall be aware that the use and

subsequent repair of this equipment may require special

training and knowledge. It is recommended that an annual

inspection be done by qualified personnel and that any

missing or damaged parts, decals, warning / safety labels or

signs be replaced with factory authorized replacement parts

only. Any spreader that appears to be damaged in any way, is

worn or operates abnormally shall be removed from service

immediately until such time as it can be repaired/replaced.

Instruction Manuals are available from manufacturer.

2

BVA Hydraulic Spreaders are designed for rated capacity

pushing and spreading. A wide variety of applications exist

for this category of product.

Special skill, knowledge and training may be required for

a specific task and the product may not be suitable for all

the jobs described above. Unsuitable applications would

include applications that call for a device to move, level

or support persons, animals, hazardous materials, mobile

homes/dwellings in general, mirrors and/or plate glass, and/

or to connect/secure hatches, components, etc. between

bulkheads. The user ultimately must make the decision

regarding suitability of the product for any given task and

therefore accept responsibility for that decision. I

mmediately

after lifting, loads must be supported by appropriate

mechanical means.

PRODUCT DESCRIPTION

NEVER

rely upon a hydraulic spreader as a support

device!

Immediately

after lifting, loads must be

supported by appropriate mechanical means.

Always check connections before using. Alteration

of these products is strictly prohibited. Use only

those adapters and attachments provided and approved

by the manufacturer.

To reduce the risk of personal injury and/or property

damage, ensure that the rated working pressure of

each pressurized attachment be equal to or greater than the

rated working pressure developed by the hydraulic pump.

!

!

!

GENERAL SAFETY INFORMATION

1. Ensure that both spreader jaws fully engage the load

and that the load is centered on the serrated portion of

each spreader jaw before pressurizing spreader. Do not

load off center.

2. Always monitor the hyraulic pressure pressure developed

in the spreader ram by using an inline pressure gauge.

These spreaders are designed to develop 10,000 psi at

rated capacity.

BEFORE USE

1. Before using this product, read the owner's manual

completely and familiarize yourself thoroughly with the

product, its components and recognize the hazards

associated with its use.

2. Verify that the product and the application are compatible.

If in doubt, call BVA Hydraulics Technical Service (888)

332-6419.

3. Inspect before each use. Do not use if bent, broken,

leaking or damaged components are noted.

4.

Replace worn or damaged parts and assemblies with BVA

Hydraulics authorized replacement parts only. Lubricate

as instructed in Maintenance Section.

5. Use ANSI compliant eye protection when operating or

near this equipment.

6. Ensure method of confirming load is accurate and working

properly. Have gauge or load cell accuracy verified by

qualified personnel on a yearly basis.

7. Spreaders should be stored where protected from the

elements, abrasive dust, and damage. These devices

may be stored in virtually any position.

!

If bowing or bending of the spreader jaws occurs,

STOP, immediately release pressure!

Evaluate

the set-up and consider a higher capacity system.

Bowing or bending of components indicates that the

spreader is overloaded.

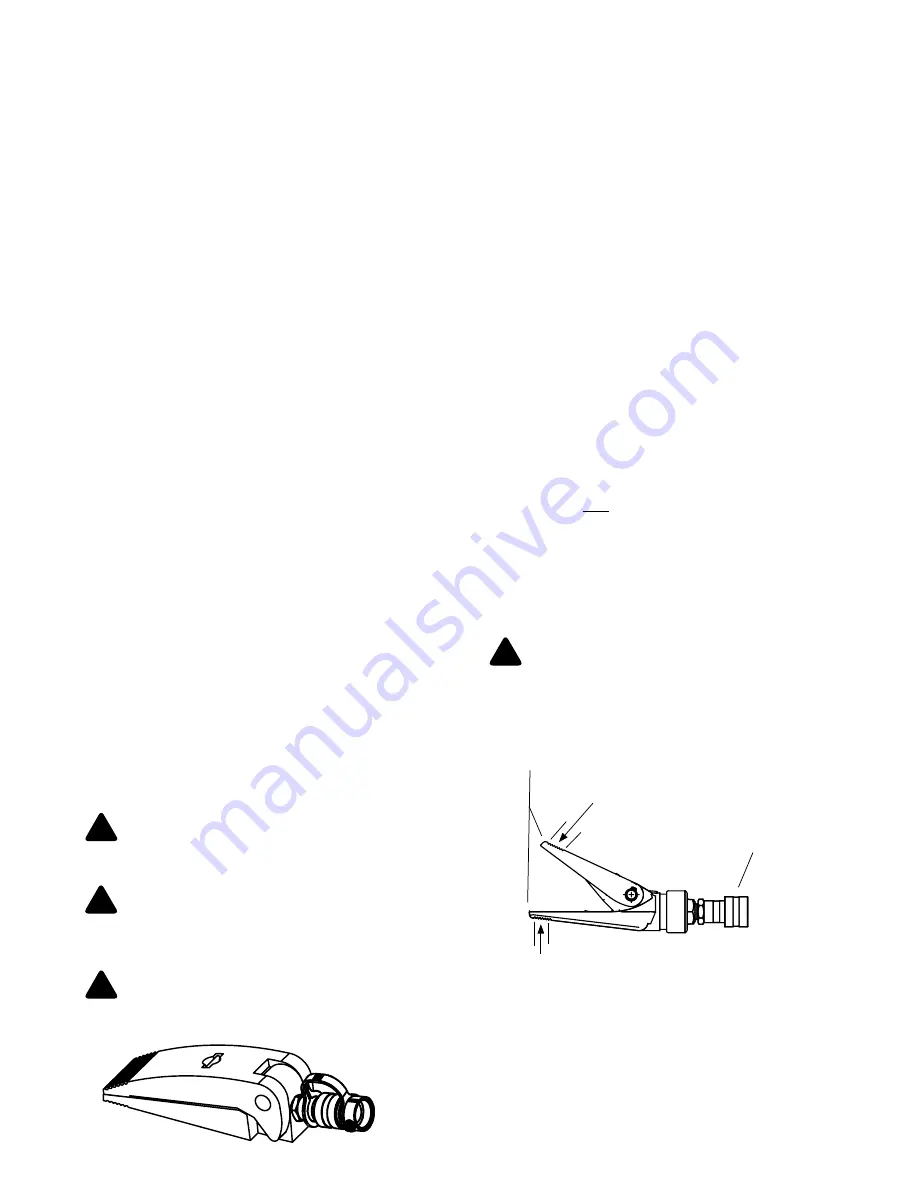

3/8”-18NPTF coupler

spreader jaws

serrated portion, centrally load

at arrow(s)

Figure 1- Typical Spreader Nomenclature

(SR05 shown)