Summary of Contents for GasAlertQuattro 1

Page 1: ...Quick Reference Guide 1 2 3 and 4 Gas Detector ...

Page 4: ......

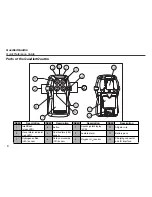

Page 11: ...7 GasAlertQuattro Screen Elements Screen Elements ...

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ...50104941 536 EN Rev F 2017 BW Technologies by Honeywell All rights reserved ...