29

EN

Recognising an imminent refill replacement:

When the red CHECK SYSTEM lamp lights up, open

the control box and check the status on the LCD.

This can be seen as an early warning for a refill repla-

cement that is soon due.

You have sufficient time to contact your dealer and

order replacement cartridges.

Recognising a necessary refill replacement:

The red CHECK SYSTEM lamp lights up and the LCD

status changes to:

Important: Always replace all refills in the working

units at the same time!

Please note that water can leak out when changing

the refills. Always have a bucket ready.

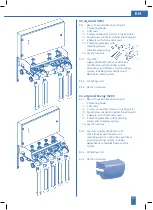

Implementing the refill replacement:

I. Disconnect the mains plug

II. Close the shut-off valves upstream

and downstream of the unit

III. Depressurize the unit with the

rinsing valve

IV. Remove the unit cladding

V. Disconnect the electrode plug on

the underside of the working unit

VI. Remove the working unit and

discharge the filling water

VII. Open the spinner nut at the end

of the working unit with the

octagonal wrench provided and

dispose of the old refill.

(domestic waste)

VIII. Insert the new refill in the work-

ing unit in the correct installation

position.

IX. Tighten the spinner nut up to the stop.

X. Connect the prepared working unit as per

the unit model as described in „5.4.

installation/assembly“.

6.14. Close control box and lock with supplied

key. Store key safely away from unauthorized

persons.

6.15. The AQA total unit is now ready for operation!

7. Maintenance

The system operator is required to carry out a

visual inspection of the system at regular intervals

(every 1 or 2 days). This should concentrate on any

installation leaks and the functionality of the AQA

total unit.

Regular maintenance is essential to ensure correct

functionality of the AQA total system.

– Check the hydraulic installation for leaks and

tight

fit

– Check the electrical installation for correct fit

and possible rust spots caused by condensate

– Check the lamps on the control unit:

Lamp signals:

POWER

Colour: yellow

Type: Permanently lit

- AQA total is

connected to mains

CHECK SYSTEM

Colour: red

Type: Permanently lit

– Refill must be replaced

or system error

IN OPERATION

Colour: green

Type: Permanently lit

- must light up with water consumption;

AQA total is treating water

Check on the LC display whether the yellow and

the green light are lit up when water is consumed.

If this is not the case or the red lamp is lit up, ple-

ase contact your specialist installer or our factory

customer services.

7.1. Refill replacement

The AQA total Energy reliably indicates when a refill

replacement is due, ensuring that the unit is always

operated at full capacity.

Prepare for refill

replacement

Efficiency low

Replace refill(s)