18

EN

8. Commissioning

8.1 Setting outlet pressure

(AQA therm HFB-1717 BA)

The factory setting of the pressure reducer is 1.5 bar.

The system pressure should be at least 2 bar higher

than the outlet pressure setting.

1. Close the shut-off ball valve on the inlet side of

the AQA therm HFB-1717 BA and on the outlet

side of the AQA therm HES.

- The outlet-side shut-off ball valve on the AQA

therm HFB-1717 BA must remain open.

2. Depressurise the outlet side by opening the sam-

pling valve (bleed valve on AQA therm HES).

3. Slacken the compression spring

- Use the adapter to get to the compression

spring. Turn the adapter to the left (-) as far as

it will go.

4. Slowly open the shut-off ball valve on the inlet side.

5. Turn the adapter until the pressure gauge reaches

the required value.

6. Re-tighten the slotted screw.

7. Slowly open the shut-off ball valve on the outlet side.

8.2 Setting AQA therm HES generation 2016

with electronical display with ‘smart’ set-up

and ‘smart’ operation

a) Remove the electronics housing, insert the battery

and replace the housing.

b) ‘Smart’ set-up:

The custom electronics of the AQA therm HES

generation 2016, with just 3 clicks, enable easy,

quick and intelligent setting of the operating

parameters, majoring on the preferred low-salt

process for natural, perfect heating water without

additives.

- no laborious searching in tables

- no fault-prone sensors

- all the attributes of modern smart metering

design and

- practical expansion options

„Smart”-operation:

Monitoring of the flushing, filling and refilling

volumes is available via the plain text display.

You can also use a ‘smart’ function to:

- turn the acoustic monitoring signal on/off

- register the relevant data

- send control signals to a solenoid valve

(available from Q4/2016)

- connect an SMS box – for sending alarm

messages to a mobile phone when cartridges

are depleted (available from Q4/2016).

c) The assigned selection fields in the display move

with each keystroke to the selected position. The

selection is logged if you pause on the position

for more than 3 seconds.

d) If the AQA therm HES operates without a cart-

ridge in the flushing process, select ‘NONE’,

and connect the flushing/dummy plug (Art.-no.

084154).

e) If the AQA therm HES is used for filling or refil-

ling, please insert the cartridge (see no. 8.7.).

Press the cartridge/cartridge button to toggle

between the different cartridges, pausing on the

selected cartridge for 3 seconds to log it.

f) The pre-defined hardness ranges for the ‘smart’ set-

up cover over 90% of the application areas. For

water hardness >26 °dH/46.3 °fH/463 ppm, the

maximum water hardness should be logged. An

estimate to the nearest litre can be seen using the

classic comparison method with the capacity tab-

le, ditto for the intermediate ranges (see cartridge

operation manual or no. 13).

g) If, according to the ‘smart’ set-up, cartridge ca-

pacity falls below 10%, the service LED will flash

yellow. When the cartridge is totally depleted, or

if the cartridge has been in use for longer than 5

years, the service display will flash red and emit

a beep. (Factory setting is tone on; to turn off, see

8.3 point h.)

h) Where necessary, use the ON/INFO button to

advance to turn the cartridge replacement sound

signal on or off, set the position required and

pause for 3 seconds to log the selection. Factory

setting: signal always on.

i) To reset the entire filling quantity in litres, please

press the ON/INFO button and the water Was-

serhärte/hardness button together for 3 seconds.

8.3 Flushing the system

Some national standards stipulate flushing the hea-

ting system, so a flushing/ dummy plug is necessa-

ry. This can be installed instead of the AQA therm

hardness-reducing cartridge (HRC) or desalination

cartridge (SRC). After flushing, reconnect the cart-

ridge to fill the system.

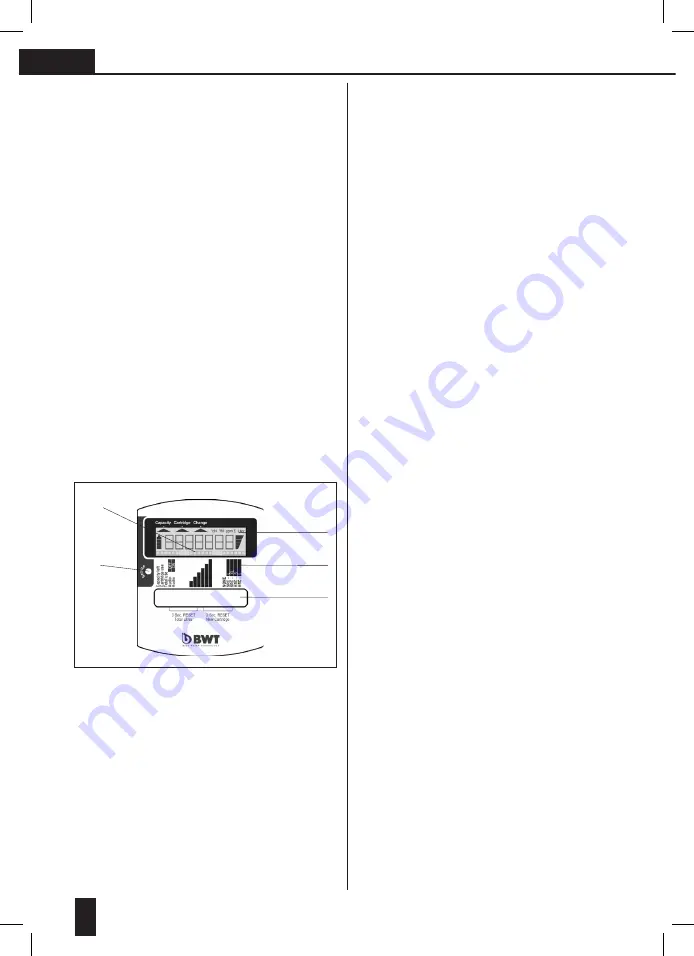

Service LED

Display

Selection

Options

Operation buttons

Selection fields

6280_EBA AQA therm HFB_HES_HWG_313660-5.indd 18

24.09.15 09:09