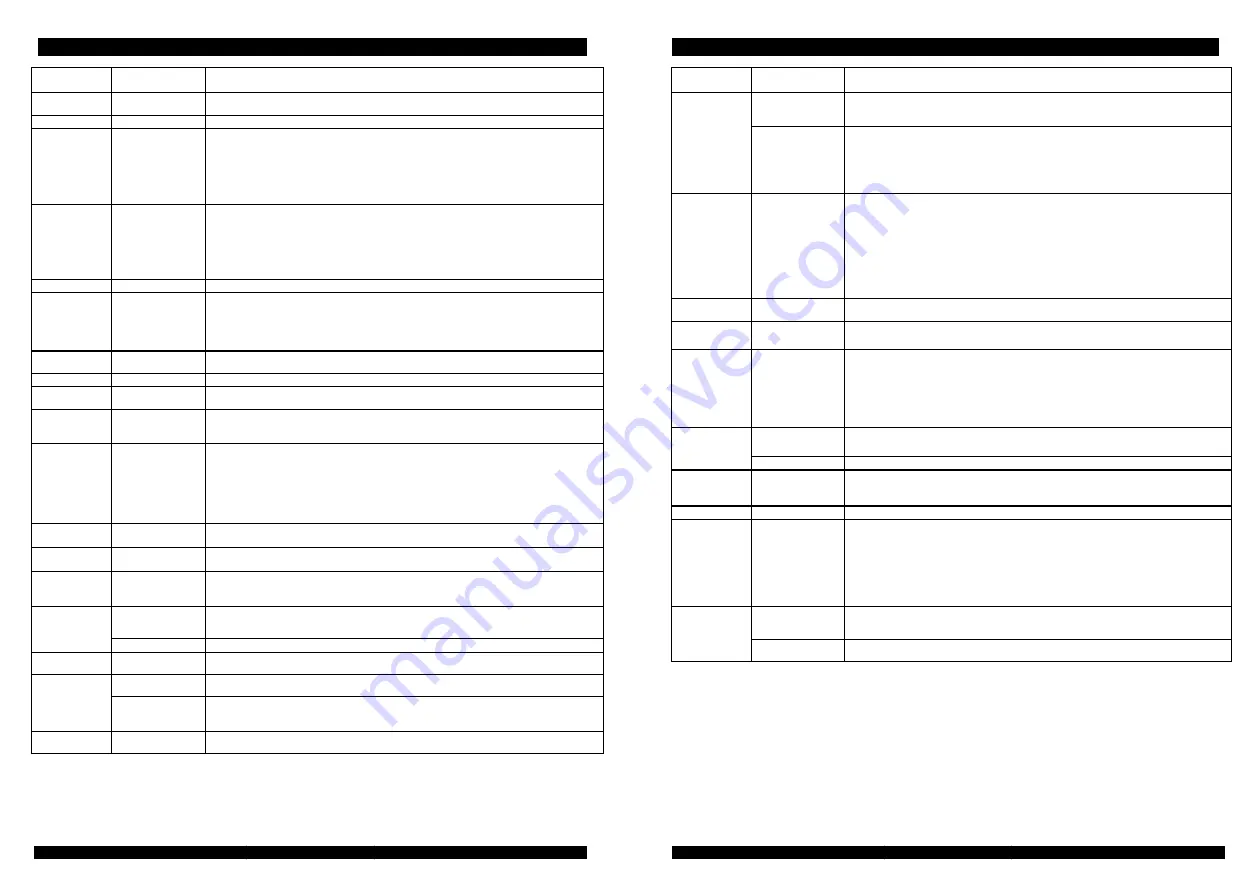

MAINTENANCE OF VEHICLES

EPS14Pi

USER MANUAL

6

6

6

7

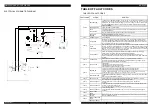

02A26

CURRENT SENS.

KO

02A27

PHASE KO

Check whether the connection among U/V/W is normal.

02A28

PUMP VMN LOW

Cause: When the machine starts, the low-end voltage of MOS transistor is 10% higher than

that of normal battery or the phase voltage is 50% higher than battery voltage.

Possible causes:

1. The wiring of the motor is incorrect or a fault is found in the circuit of the motor; check

whether the three-phase connection is correct; check whether there is electric leakage in the

motor connecting to the ground; check whether the coil of the motor is broken.

2. Replace the controller.

02A29

PUMP VMN HIGH

Cause: When the machine starts, the low-end voltage of MOS transistor is 10% higher than that

of normal battery or the phase voltage is 50% higher than battery voltage.

Possible causes

:

1. The wiring of the motor is incorrect or a fault is found in the circuit of the motor; check

whether the three-phase connection is correct; check whether there is electric leakage in the

motor connecting to the ground; check whether the coil of the motor is broken.

2. Replace the controller.

02A30

vmn low

Check the three-phase line of the motor.

02A31

vmn high

Cause: When the machine starts, the low-end voltage of MOS transistor is 10% higher than

that of normal battery or the phase voltage is 50% higher than battery voltage.

Possible causes

:

1. The wiring of the motor is incorrect or a fault is found in the circuit of the motor; check

whether the three-phase connection is correct; check whether there is electric leakage in the

motor connecting to the ground; check whether the coil of the motor is broken.

2. Replace the controller.

02A32

PUMP VMN NOT

OK

02A37

contactor closed

Check whether the master contactor adheres.

02A38

contactor open

1. The circuit of the master contactor coil disconnects.

2. The main contactor is broken.

02A40

AUX DRIV.SHRT.

Check whether the short circuit or low impedance push-pull output exists between A16 and

–BATT.

If a circuit fault appears in the driver of the logic card, replace the controller.

02A41

WRONG

BATTERY

When starting, check battery voltage with the controller and determine whether it reaches what is

allowed.

1.

Check whether the value of BATTERY VOLSIGNE on the TESTER menu is consistent with

that on the voltmeter. If not, use ADJUST BATTERY function and change the battery voltage to

match the measured value.

2.

Replace the battery.

02A42

AUX DRIV.OPEN

The driving circuit of the auxiliary coil can’t drive load. The device itself or driving coil is broken.

Replace the controller.

02A47

EVP2 NOT OK

Check whether the input voltage of NAUX2 is normal. If not, re-mark the maximum and

minimum values of NAUX2 and restart the key. Then the fault disappears.

02A48

EVP1 NOT OK

Check whether the input voltage of NAUX1 is normal.

If not, re-mark the maximum and minimum values of NAUX1 and restart the key. Then the fault

disappears.

02A49

LIFT + LOWER

1. Operation is inappropriate.

2. It is blamed for faults of lifting and descending switches.

3. Replace the controller.

i=0 ever

If the three-phase connection is correct, replace the controller.

02A50

EVP1 COIL OPEN

Check whether the coil of NAUX1 is set as the open circuit or whether the type of EVPI is set

correctly.

02A51

EVP2 COIL OPEN

Check whether the coil of NAUX1 is set as the open circuit or whether the type of EVPI2 is set

correctly.

TILLER

OPEN

When the handle input switch disconnects, the master contactor will disconnect and report an

alarm after about 30 seconds. The alarm will not disappear until the master contactor runs

again.

02A52

PUMP I=0

EVER

Check whether it is correct in the connection among power lines of the oil-pump motor; if yes,

replace the controller.

02A53

STBY I HIGH

The signal output from the current sensor, detected by the microcontroller, exceeds what is

allowed by the inactive current. Since the fault is irrelevant with peripheral components, just

replace the controller.

WRONG ZERO

When it starts, the feedback value on the high-end voltage of VMN is not around 2.5V. The

circuit of the controller

is broken.

Fault analysis: recommend to check the following items.

Connection inside the motor.

Connection among motor power cables.

Drain current between the motor and the forklift housing.

If the

connection of the motor is

good, check the controller and replace it.

02A54

LOGIC FAILURE

#1

It is a fault caused by low-voltage or over-voltage protection. Under a 24V system, the

controller detects that the voltage is over 45V or below 9V; while under a 45V system, it is

over 65V or below 11V.

Possible causes:

1. Check whether a short circuit appears in the circuit system, such as DC-DC, brake coil, or

check whether the input power of the controller is connected well.

2. Check whether the battery voltage is too low or too high.

3. Detect B+ and B, and check whether the power cable over the binding post of the master

contactor is tightened well.

4. Check whether calibration parameters of controller voltage are consistent with those of

actual voltage.

For the hardware circuit fault with overvoltage protection on the logic card, replace the

controller.

02A55

LOGIC FAILURE

#2

For it is a fault on the phase-voltage feedback hardware circuit of the logic card, replace the

controller.

02A56

PUMP I NO

ZERO

Replace the controller

02A60

CAPACITOR

CHARGE

When the electric lock is turned on, the controller will charge the capacitance through a power

resistor and

detect whether the capacitance is overcharged in the regulated time. If the capacitance is

in insufficient

power and voltage thereof

is still 20%

lower than that of the battery, the controller will alarm and thereby the

master contactor will not closed down. Possible causes:

1.

If peripheral devices such as DC-DC and motor, or other devices interfere with the charging of the

controller,

interference on these devices should be eliminated.

2.

If the charging resistance disconnects and faults are found in the charging circuit and

power models, the

controller should be replaced. The output signal of temperature sensor of the controller exceeds what is

allowed.

02A61

THERMIC SENS.

KO

The output signal of temperature sensor of the controller exceeds what is allowed. Since the

fault is irrelevant with peripheral components, just replace the controller.

high temperature

Measure the temperature of the controller board.

02A62

TH.

PROTECTION

Drop the temperature of the controller below 85°. If the fault still exists, it may be blamed for

the temperature sensor or the logic board of the controller itself. Replace the controller at this

time.

02A64

TILLER ERROR

Replace the controller.

02A65

MOTOR

TEMPERAT.

1. The fault appears when the temperature digital switch of the motor turns on or when the

analog signal exceeds the switch-off value.

2.When the temperature of the motor reaches 120

℃

, the controller will alarm. By this time, the

forklift still can move, but the maximum current is cut and the performance of the forklift is

reduced. When the temperature of the motor reaches 125

℃

, the motor stalls working where it

should be cooled down.

3. If the fault still exists when the motor cools down, check the circuit. If necessary, replace the

controller.

02A67

SENS MOT

TEMP KO

The output signal of temperature sensor of the controller exceeds what is allowed.

Check the value of the sensor and the connection of cables. Otherwise, it should be blamed for

the inside of the controller.

NO CAN MSG.

It is a fault about CAN communication between the steering and traction. Check the setting of

CAN connection and the software, and version information.

FAULT

CODE

ALARM

REMEDY

FAULT

CODE

ALARM

REMEDY

OM-

EPS14Pi

2019001-EN