English

11

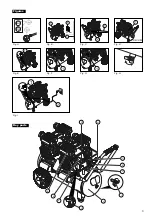

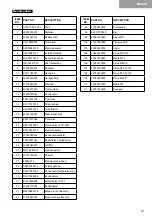

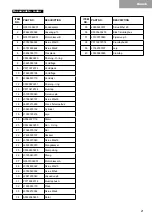

Key parts

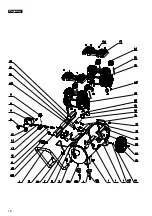

Parts description - see drawing on page 3

A

ELECTRIC MOTOR:

The motor is used to power the pump. It is equipped with a thermal overload

protector. If the motor overheats for any reason, the thermal overload protector will shut it down in order

to prevent the motor from being damaged.

B

AIR COMPRESSOR PUMP:

The pump compresses the air and discharges it into the tank via the piston

that moves up and down in the cylinder.

C

SAFETY VALVE:

This valve is used to prevent the compressor from building too much pressure. If the

pressure reaches the preset level of the safety valve, it will automatically pop open.

D

PRESSURE SWITCH

: This switch turns on the compressor and is operated manually.When in the

ON position, it allows the compressor to start up or shut down automatically, without warning, upon air

demand.ALWAYS set this switch to OFF when the compressor is not being used and before unplugging

the compressor.

E

PRESSURE REGULATOR KNOB:

The regulator is used to adjust the pressure inside the line to the

tool that is being used. Turn the knob clockwise to increase the pressure and counter-clockwise to

decrease the pressure.

F

TANK PRESSURE GAUGE:

The gauge measures the pressure level of the air that is stored in the tank.

It cannot be adjusted by the operator and it does not indicate the pressure inside the line.

G

OUTLET PRESSURE GAUGE:

The gauge measures the regulated outlet pressure.

H

QUICK COUPLER

: The quick coupler is connected to a quick connector which is connecting to air hose.

I

DRAIN VALVE

: The drain valve is used to remove moisture from the air tank after the compressor is

shut off.

J

AIR TANK:

The tank is where the compressed air is stored.

K

POWER CORD:

This product is for use on a nominal 230-volt circuit and should be grounded. A cord

with a grounding plug must be used. Make sure that the product is connected to an grounded outlet that

has the same configuration as the plug (see Fig. A). No adapter should be used with this product. Check

with a licensed electrician if the grounding instructions are not understood or there is doubt as to whether

the product is properly grounded. If the plug does not fit the outlet, have a proper grounded plug installed

by a licensed electrician.

!

DANGER:

Improper installation of the grounding plug will result in

a risk of electric shock. If repair or replacement of the

cord or plug is necessary, do not connect the ground-

ing wire to either flat blade terminal. The outer surface

of grounding wire is mixed with yellow and green.

General safety warnings

• Do not operate the compressor until you have

read and understand this instruction manual for

safety, operation and maintenance instructions.

WARNING:

•

Risk of fire caused by sparks from motor and pres

-

sure switch could result in death or serious injury.

•

Do not operate compressor near flammable gas

or vapor. Never store flammable liquids or gas in

vicinity of compressor.

• High pressure air could result in death or serious

injury. Shut off unit, unplug and release air pressure

prior to servicing.

• Never operate above maximum operating pressure

of the nailer/stapler.

• Drain water from tank after each use.

• Do not weld or repair tank.

• Do not operate with pressure switch or safety valve

set above maximum allowable working pressure.

• Hot compressors surfaces could result in serious

injury. Allow compressor to cool before touching.

•

Using compressor to supply breathing air could

result in death or serious injury.

•

Do not spray flammable materials in vicinity of any

flame or ignition sources including the compressor.

• Do not restrict compressor ventilation openings or

place objects against or on top of the compressor

• Operate compressor only in a clean, dry, well

ventilated area.

•

Do not operate unattended. Always turn off and

unplug the compressor when not in use.

!

Summary of Contents for 3,0HK OLIEFRI

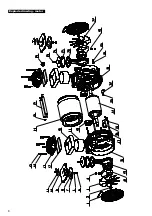

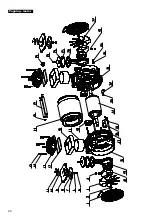

Page 6: ...6 Explode drawing...

Page 8: ...8 Explode drawing motor...

Page 18: ...18 Tegning...

Page 20: ...20 Tegning motor...

Page 28: ...Bygma Transformervej 12 DK 2860 S borg tlf 45 44 54 17 00 indkoeb bygma dk 12 21...