12

• Risk of serious eye injury from moisture

and debris. Operators and others in work area

shall wear CE approved and impact-resistant eye

protection with side shields when working with the

compressor and/or opening the drain valve.

• Do not spray any part of the body.

• Shock risk could result in death or serious injury.

Only connect the compressor to a properly ground-

ed receptacle.

• Dust can be created when cutting, sanding,

drilling or grinding materials such as wood, paint,

metal, concrete, cement, or other masonry. To

reduce your exposure to these chemicals, work in

a well ventilated area and ALWAYS wear approved

safety equipment.

•

KEEP CHILDREN AWAY FROM THE COMPRES

-

SOR AT ALL TIMES.

CAUTION:

• High pressure air containing water condensation

could result in minor or moderate injury. Do not

spray at any person.

NOTICE:

•

If the pump has been transported or turned upside

down (even partially), allow the pump to sit in a nor-

mal, upright position for approximately 10 minutes

before starting.

Assembly instructions

•

Unpack the compressor. Inspect the compressor

for damages. If the compressor has been damaged,

contact your dealer immediately.

•

Check the air compressor’s identification label to ensure

that you have purchased the intended model and that it

has the required pressure rating for its intended use.

• The carton should contain the compressor and

these safety and operation instructions.

Positioning of the air compressor

1.

Position the air compressor (1) near an electrical

outlet (2) (Fig. B).

2.

The compressor must be at least 31 cm from any

wall (3) or obstruction, in a clean, well-ventilated area

to ensure sufficient air flow and cooling (Fig. B).

3.

Place the compressor on the floor or a hard, level

surface.The compressor must be level to ensure prop-

er drainage of the moisture in the tank.

Connect air hose to compressor

1.

Connect the air hose (1) to the compressor’s quick

coupler (2) (Fig. C).

Operating instructions

Break in the pump

1.

Set the pressure switch (1) to the OFF position (Fig. D).

2.

Open tank drain valve (1) by turning it counter-clock-

wise to permit the air to escape and prevent air

pressure build-up in the air tank during the break-in

period (Fig. E).

3.

Turn the pressure knob (1) clockwise until it stops

(Fig. F).

4.

Plug in the power cord

∙ Use a dedicated circuit.

If any other electrical de

-

vices are drawing from the compressor’s circuit,

the compressor may fail to start or an overload

circuit can result in sluggish starting that causes

the motor overload protection system or circuit

breaker to trip, especially in cold conditions.

∙

Disconnect the power cord only after break-in

process has been completed, otherwise the

motor might get damaged.

5.

Set the pressure switch (1) to the ON position (Fig.

D). The compressor will start. Run the compressor for

30 minutes. If it fails, turn it off immediately.

Please note that breaking-in the unit is only required

prior to first use.

6.

After 30 minutes, turn off the pressure switch.

7.

Close the tank drain valve (1) by turning it clockwise

(Fig. E).

8.

Set the pressure switch to the ON position. (Fig. D)

The air receiver will fill to “cut-out” pressure and then

the compressor’s motor will stop. The compressor is

now ready for use.

Before each start-up

1.

Set the pressure switch (1) to the OFF position (Fig.

D).

2.

Turn the pressure regulator knob (1) counterclock-

wise until it stops (Fig. G).

3.

Attach hose and accessories (Fig. C)

∙

When using an extension cord or extension cord

reel, be sure to use a 3-core flexible cable:

◦ Up to 10m → 3 × 1.5 mm

2

.

◦ Up to 20m → 3 × 2.5 mm

2

.

How to start

1.

Close the tank drain valve (1) (Fig. I)

2

. Plug-in the power cord (2) (Fig. I)

3.

Set the pressure switch to the ON position and allow

the tank pressure to build (Fig. D). Motor will stop

when tank pressure reaches cut-out pressure.

4.

Turn the air pressure regulator knob clockwise until

desired pressure is reached (Fig. F).

5.

The compressor is ready for use.

How to shut down

1.

Set the pressure switch (1) to the OFF position

(Fig. D).

2.

Unplug the power cord (2) (Fig. I).

3.

Set the tank drain valve (1) to ON to ensure the tank

is drained (Fig. I).

WARNING:

Do not unplug the compressor while it is running, as

it will cause malfunction when plugging in again, and

pose great risk of burning the compressor unit.

!

!

Summary of Contents for 3,0HK OLIEFRI

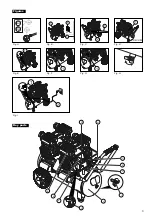

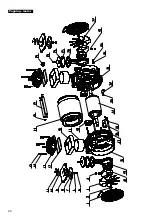

Page 6: ...6 Explode drawing...

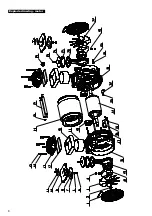

Page 8: ...8 Explode drawing motor...

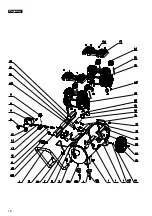

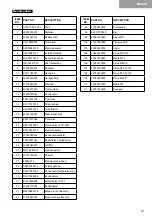

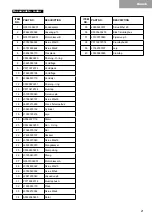

Page 18: ...18 Tegning...

Page 20: ...20 Tegning motor...

Page 28: ...Bygma Transformervej 12 DK 2860 S borg tlf 45 44 54 17 00 indkoeb bygma dk 12 21...