English

15

Problem

Possible cause

Solutions

The pressure is low or there is

not enough air.

There is a leak at one of the

fittings.

Check the fittings with soapy water. Tighten or reseal leaking fittings

(apply plumber s tape on threads). Do not over tighten.

The tank drain valve is open. Close the drain valve.

The air intake is restricted.

Clean or replace the air filter elements.

Prolonged excessive use

of air.

Decrease the amount of air used.

There is a hole in the air

hose.

Check the air hose and replace it if necessary.

The tank leaks.

Replace the tank immediately. Do not attempt to repair it.

The valve is leaking.

Check for worn parts and replace them if necessary.

There is moisture in the

discharge air.

There is condensation in the

air tank caused by a high

level of atmospheric humidity

or because the compressor

has not been running long

enough.

Drain the air tank. Drain the air tank more often in humid weather

and use an air-line filter.

The compressor overheats.

The ventilation is inadequate. Relocate the compressor to an area with cool, dry and well-circu-

lated air.

Cooling surfaces are dirty.

Clean all cooling surfaces on the pump and the motor thoroughly.

The valve is leaking.

Replace worn parts and reassemble using new plumber’s tape.

For failure other than above situations, please stop using the compressor and contact an authorized service center.

Summary of Contents for 3,0HK OLIEFRI

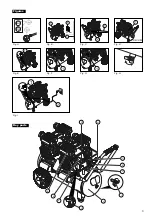

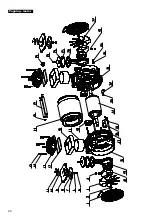

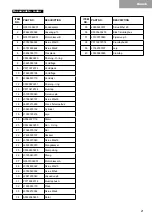

Page 6: ...6 Explode drawing...

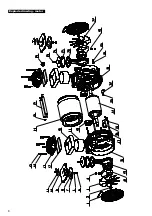

Page 8: ...8 Explode drawing motor...

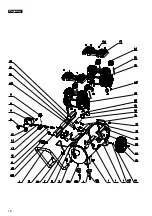

Page 18: ...18 Tegning...

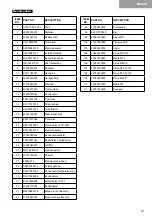

Page 20: ...20 Tegning motor...

Page 28: ...Bygma Transformervej 12 DK 2860 S borg tlf 45 44 54 17 00 indkoeb bygma dk 12 21...