English

7

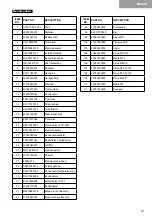

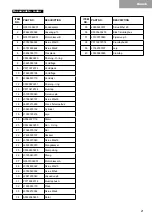

Spare parts

ITEM

NO.

PART NO.

DESCRIPTION

1

AT2515.00.00.01

Tank

2

J8335250201

Metal tube

3

J0907040313

Drain valve

4

X3110590032

Rubber foot

5

D9000084139

Crimping cap

6

D9079865177

Connecting line

7

JAE46710733

Protect the frame

8

Q4726521001

Lock button

9

J3266600414

Handle

10

X3111020031

Handgrip

11

J2993490675

Quick coupler

12

J7104880061

Manifold

13

J0304870463

Pressure regulator

14

J2469930042

Check valve

15

F5013701079

Pressure gauge

16

D1011073274

Power cord

17

D3005000147

Pressure switch

18

J0023160647

Safety valve

19

F5013701083

Pressure gauge

20

Q5911245001

Crimping board CC1103W

21

D5010003001

Crimping cap

22

J7383090034

Capacitor shroud

23

F0000901043

Heat shroud

24

J3095040201

Air filter

25

Q411A263001

Muffler tube

26

J3161200423

Elbow fitting

27

2556C273

Motor pump assembly

28

X0004360212

Cushion pad

29

X4207350167

Capacitor fixing ring

30

D6015006026

Capacitor

31

Z1240000256

Crimping board CLT-1

32

J5638170344

End cap

33

D9079865178

Connecting line

34

J7432360249

Solenoid valve

ITEM

NO.

PART NO.

DESCRIPTION

35

J0189940407

Check valve

36

F4813700569

Roller components

101

J2981850040

Washer Ø10

102

J0191860022

Spring washer Ø10

103

J2984440032

Washer

104

J0802430032

Screw M10X20

105

J2021830040

Nut M10

106

J0782410032

Screw M5X10

107

J0782380299

Screw ST4.8×14F

108

J0783470485

Screw ST3.9×14F

109

J0783480674

Screw M4X17

110

J2020810033

Nut M8

111

J2851380428

Shaft

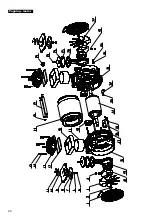

Summary of Contents for 3,0HK OLIEFRI

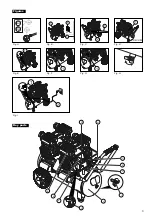

Page 6: ...6 Explode drawing...

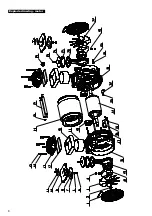

Page 8: ...8 Explode drawing motor...

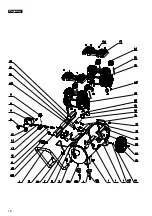

Page 18: ...18 Tegning...

Page 20: ...20 Tegning motor...

Page 28: ...Bygma Transformervej 12 DK 2860 S borg tlf 45 44 54 17 00 indkoeb bygma dk 12 21...