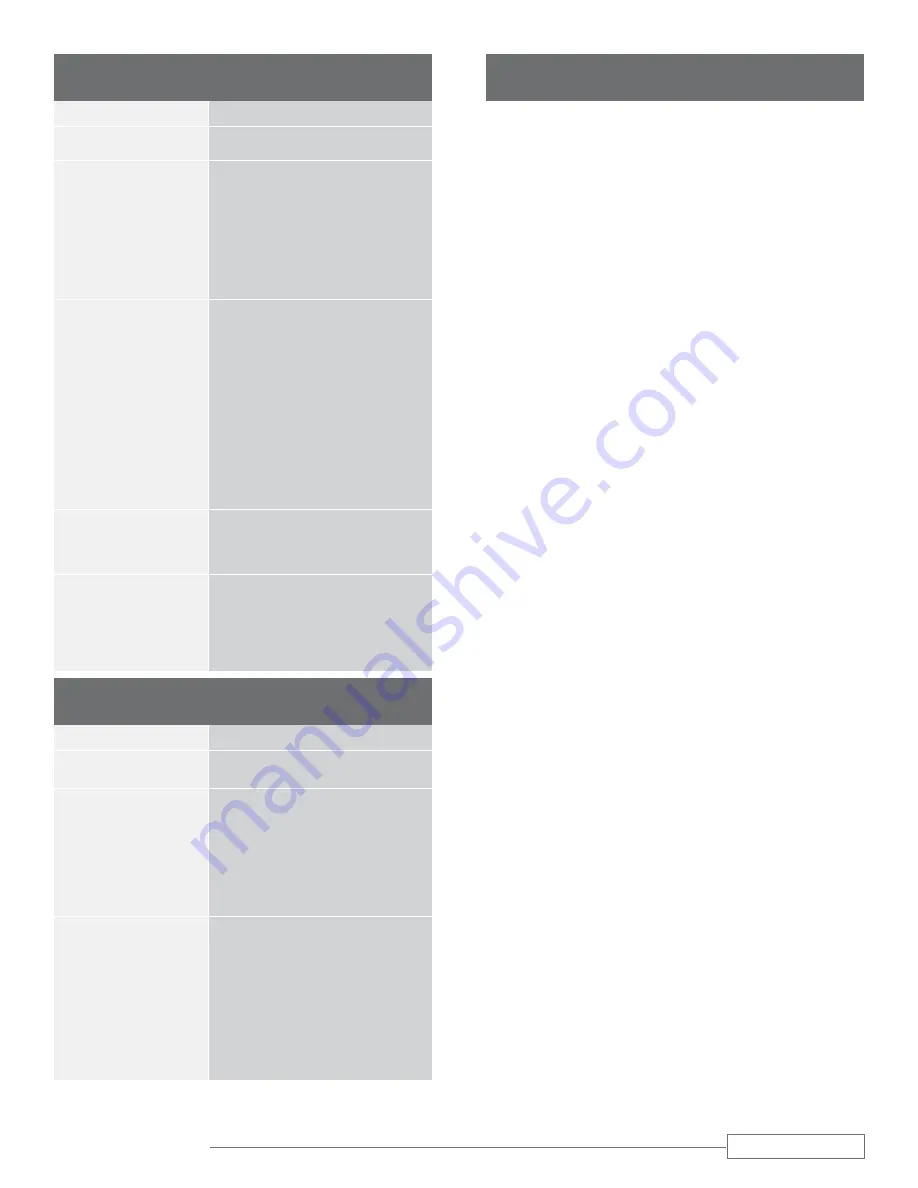

POTENTIAL ISSUE

Out of liquid solution

Blockage in the nozzle

or liquid tip

Spray appears weak

Damage to liquid hose

or peristaltic pump

tubing

No Liquid Flow

CORRECTIVE ACTION

Inspect product container for

solution level and replace if empty.

Power down and unplug the unit.

Visually inspect nozzle from

outside for blockages.

Note: Sprayer assembly, includ-

ing the nozzle, is non-service-

able. If there are problems with

obstructions in the sprayer or

nozzle assembly, please

contact Service Tech Team.

The user should power the unit

off, unplug from the wall and seek

out a different electrical outlet

to try. If unavailable, they should

look to see if other devices are

running on the same electrical

circuit. Power those off if neces-

sary. This could be a result of an

underrated extension cord. If an

extension cord is being used,

remove and test the unit while

using only the connected power

cord. See the extension cord

section for more information.

Inspect the liquid line for kinks

and/or damage. Visit

www.servicetechteam.com

to request replacement parts.

If unit has been stored without

use for extended period of time,

peristaltic pump may not operate

properly upon startup. The user

should run the unit for 5 minutes

prior to use.

POTENTIAL ISSUE

Damage to the

air hose

Blockage in the nozzle

Compressor not

starting properly.

CORRECTIVE ACTION

Inspect hose for knicks, damage

or areas where air is escaping.

Power down and unplug unit.

Visually inspect nozzle from out-

side for blockages.

Note: Sprayer

assembly, including the nozzle,

is non-serviceable. If there are

problems with obstructions in

the sprayer or nozzle assembly,

please contact Service Tech Team.

If the air compressor does not

come up to speed when pressing

the trigger, this may be a sign

that the unit has been stored

below 55°F (12.5°C)

If unit has been stored where

temperatures are below 55°F

(12.5°C) move the unit to a warm

environment and allow the unit

to acclimate before operation.

AIR PRESSURE SEEMS LOW OR WEAK

EQUIPMENT WARRANTY

THE BYOPLANET

®

MS-700™ ELECTROSTATIC SPRAYER

COMES WITH A ONE-YEAR LIMITED WARRANTY. PLEASE

REFER TO THE MANUFACTURER’S WARRANTY POLICY

FOUND AT

WWW.SERVICETECHTEAM.COM.

ENGLISH | 11

BYOPLANET.COM

NO SPRAY, ERRATIC SPRAY

OR WEAK SPRAY