5

INLET AND DISCHARGE PIPING

!

CAUTION

: Do not operate unit without inlet-air filtration�

If the air is dirty, pipe the filter to a source of clean air�

Do not install piping with a diameter lower than that of the pump

intake�

!

CAUTION

: Do not use PVC plastic in the discharge line�

Use hand-welded or threaded steel or copper pipes and cast-iron

fittings that are safe for the discharge pressure and temperature�

ELECTRICAL

!

WARNING

: Compressor installation must be performed

by a qualified electrician in accordance with the National

Electrical Code (NEC) or the Canadian Electrical Code

(CEC), the National Electrical Safety Code (NESC) OSHA

code, and/or any local or state codes having precedence�

Be sure of proper wire sizing and that the circuit breaker and the

distance from the breaker is within suggested range� Confirm your

electrical-supply voltage matches what is required for the motor�

!

WARNING

: The compressor must be grounded� Ground-

ing reduces the risk of electric shock� Certain C-Aire

Models are equipped with a cord that has a grounding

wire with a grounding plug� The plug must be plugged

into an outlet that is installed and grounded in accor-

dance with all local codes and ordinances�

!

WARNING

: Improper installation of the grounding

plug will result in a risk of electric shock� When repair

or replacement of the cord or plug is required, do not

connect the grounding wire to either flat-blade terminal�

The insulated wire with a green outer surface and yellow

stripes is the grounding wire�

NOTE

: The installation, electric motor, wiring, and all electrical

controls must be in accordance with NFPA 70-1996 National

Electric Code, National Electric Safety Code, and state and local

codes� Failure to abide by the national, state, and local codes may

result in physical harm and/or property damage�

!

DANGER

: High voltage may cause personal injury or

death� Disconnect and lockout/tagout, per OSHA reg-

ulation 1910�147, all electrical power supplies before

opening the electrical enclosure or servicing�

!

DANGER

: Never assume a compressor is safe to work on

if it is not operating� It could restart at any time� Always

disconnect/ lockout/tagout before servicing�

!

CAUTION

: Dry pipe sprinkler compressor must be wired

to a reliable power source to be compliant with AHJ�

NOTE

: Wiring diagrams for each model type are located on the

following page�

(ELECTRICAL CONTINUED ON NEXT PAGE)

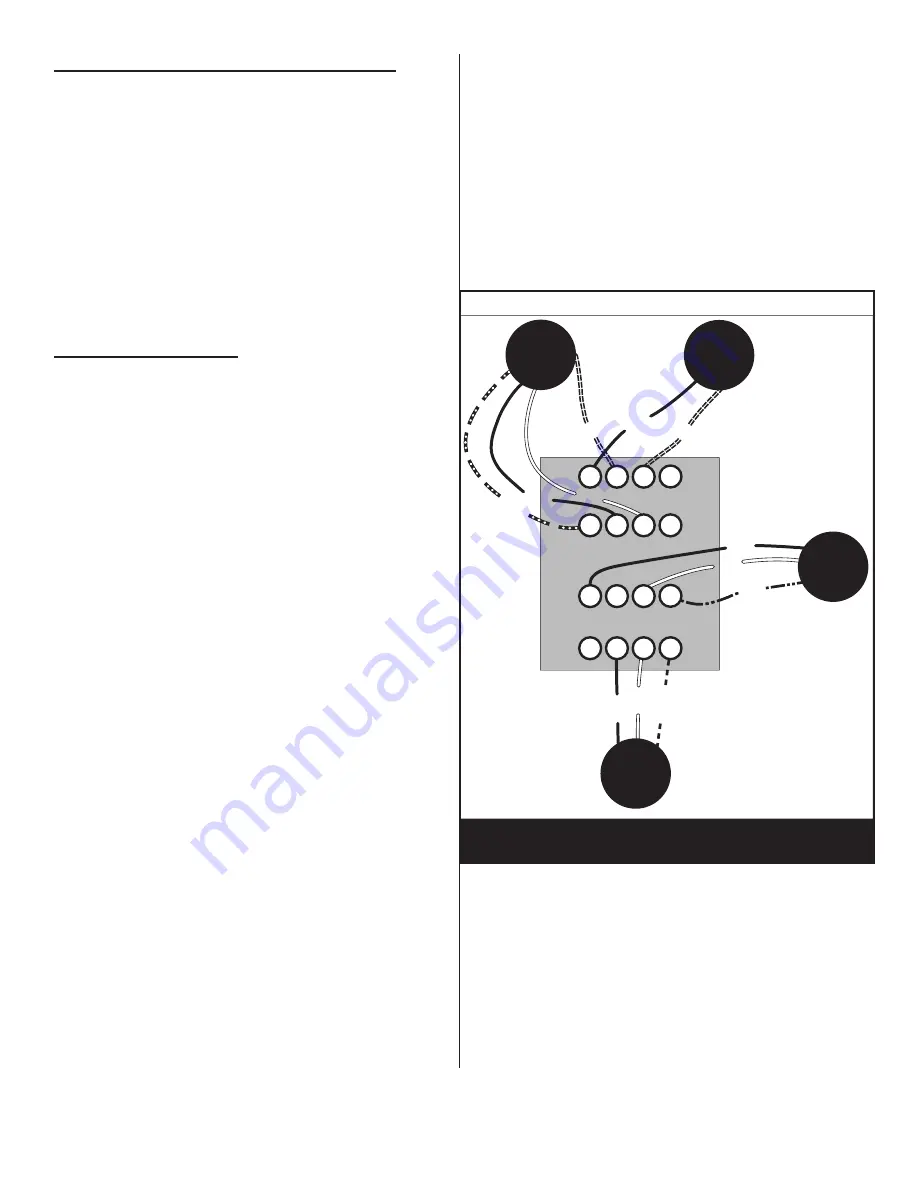

WIRING DIAGRAM

S281 DIGITAL AMD

WHITE

BLA

CK

RED

YELL

OW

BLA

CK

BLACK

LT

. GREEN

WHITE

GREEN

WHITE

BLACK

RED

SOLENOID

AMD

POWER

IN

MOTOR