5

Operating instructions for the hand-

held plane

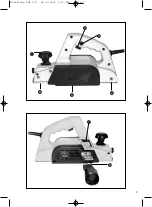

MACHINE DESCRIPTION

1

Knob for setting the planing depth

2

ON/OFF switch

3

Safety lock-off

4

Rear baseplate

5

Belt guard

6

Front baseplate

7

Chip outlet

8

Adapter for chip extraction

USE

The electric hand-held plane is for the planing,

rebating and chamfering of wooden parts.

POWER SUPPLY

Before using your machine for the first time, make

sure your power supply is the same as that specified

on the type plate. Under no circumstances should

your power supply exceed that specified by more

than 10%.

SWITCH

The electric hand-held plane is equipped with a

safety switch to prevent accidents. To switch the

machine on, press the lock-off button on the side of

the machine and then press the ON switch. To

switch off the hand-held plane, release the ON

switch, which will then jump back to its starting

position.

CHIP EXTRACTION

For optimum chip extraction, you can use the

adapter supplied to connect the hand-held plane to a

chip extraction system.

Slide the adapter over the chip outlet on the side of

the machine. You can now attach a suitable chip

extraction system to the round socket on the adapter.

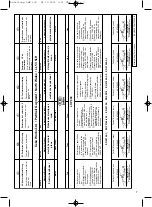

USING THE MACHINE

Important: The electric hand-held plane must be

switched on before coming into contact with the

workpiece.

Setting the planing depth

The planing depth can be set between 0 and 2 mm

by turning the setting and guide knob to the left or

right. Always turn the knob until it engages.

When you have finished working with the plane, set

the planing depth so that the knife is lowered and

protected against damage.

Planing flat surfaces

Set the desired planing depth. Place the front

baseplate of the electric hand-held plane on the

workpiece and switch it on. Holding the plane in both

hands, slide it over the surface, making sure both the

front and rear baseplates are lying flat on the

workpiece.

To finish the planed surface, set a very low planing

depth and rework the planed surface as often as

necessary.

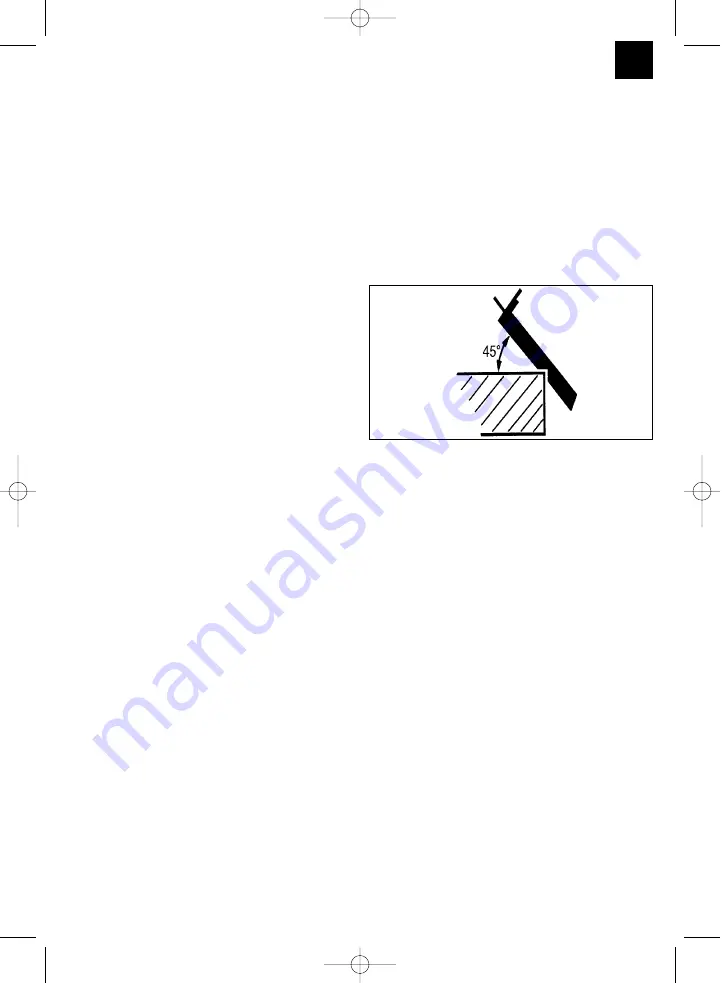

Chamfering edges (45°)

You can chamfer edges to 45° both quickly and

easily by making use of the V-groove in the front

baseplate of the plane. Position the V-groove of the

plane on the edge to be chamfered and guide it

steadily along the edge, always retaining the same

angle.

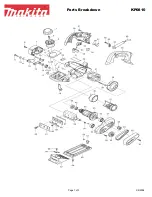

Changing the planing knives

Important: Before doing any work on the

machine, always disconnect it from the mains

first.

The electric hand-held plane is equipped with two,

carbide-tipped, double-sided knives. These knives

have two blades and can be turned over. The guide

groove ensures that the planing depth remains the

same, even after the knife has been turned. Worn,

blunt or damaged blades must be replaced.

Carbide-tipped, double-sided knives cannot be

resharpened.

Loosen the three hexagonal screws (9) with the

enclosed spanner and, using a piece of wood, push

the carbide-tipped, double-sided knife sideways out

of the knife block.

GB

Anleitung LHP 600 24.10.2001 9:51 Uhr Seite 5