RETENTION PENSTOCK

FL SERIES

C.M.O.

Amategui

Aldea

142,

20400

Txarama

‐

Tolosa

(SPAIN)

MAN

‐

FL.ES00

Tel.

National:

902.40.80.50

Fax:

902.40.80.51

/

Tel.

International:

34.943.67.33.99

Fax:

34.943.67.24.40

cmo@cmo.es

http://www.cmo.es

page 9

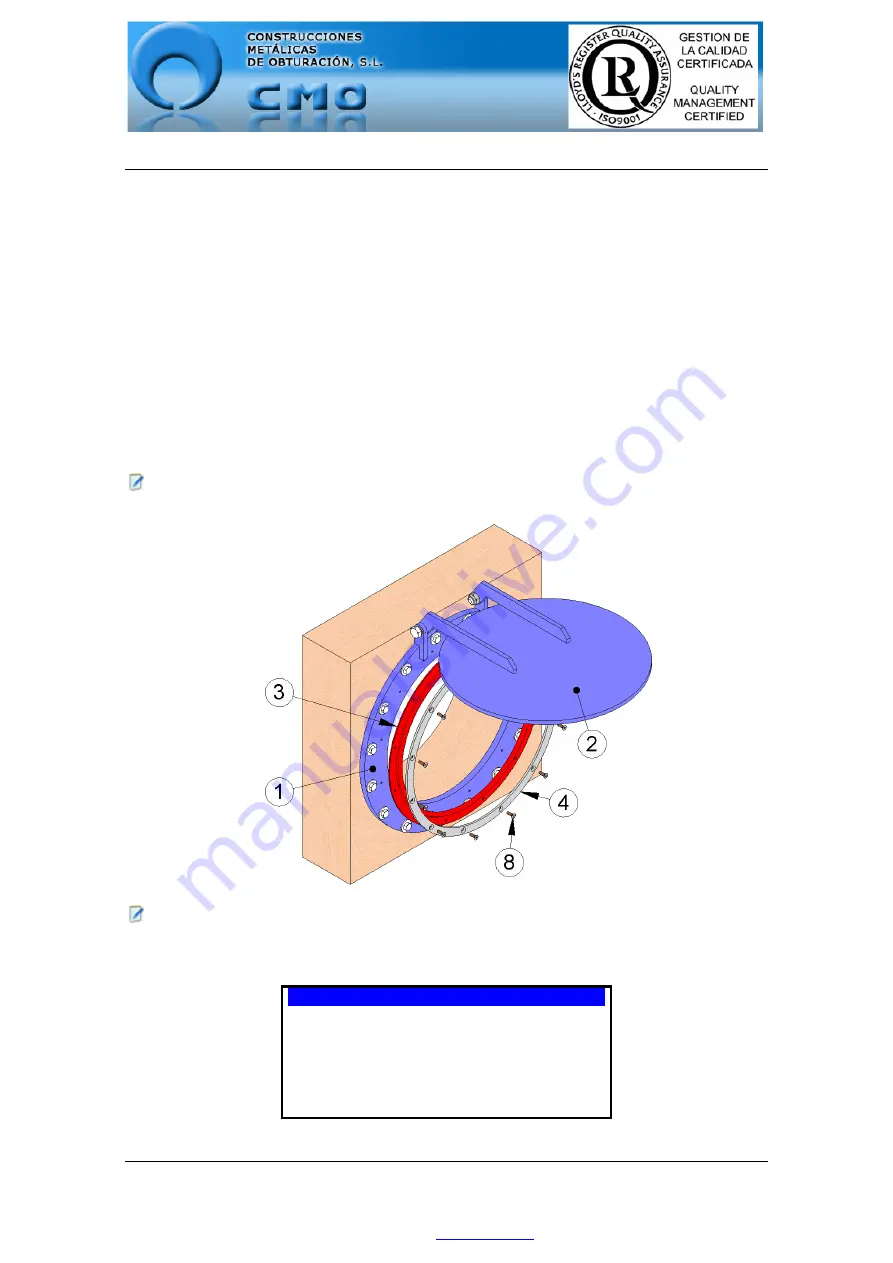

REPLACING

THE

SEALING

JOINT

1.

Make

sure

there

is

absolutely

no

pressure

or

fluid

in

the

facility.

2.

Place

the

flap

(2)

in

completely

open

position.

3.

Secure

the

flap

(2)

in

this

position

using

more

than

one

system.

4.

Unscrew

and

remove

the

screws

(8)

from

the

flange

(4)

and

the

seal

(3).

5.

Remove

the

flange

seal

(4)

and

finally

the

deteriorated

seal

(3).

6.

Clean

the

seal

housing

(3).

7.

Fit

a

new

sealing

joint

(3)

with

the

same

dimensions

as

the

old

one.

8.

Return

the

flange

(4),

checking

that

it

is

correctly

fitted

and

the

seal

(3)

has

not

been

damaged

in

the

process.

9.

Remove

the

systems

to

secure

the

flap

(2)

in

open

position,

and

carefully

position

it

in

closed

position.

10.

Before

starting

up

the

installation,

check

that

the

flap

(2)

swivels

freely

on

its

turning

point;

also

check

that

the

flap

(2)

sits

perfectly

on

the

closing

seal

(3)

when

the

penstock

is

closed.

Note:

The

numbers

in

brackets

refer

to

fig.

11.

Note:

During

the

assembly

of

the

new

sealing

joint,

it

is

recommended

to

apply

petroleum

jelly

to

the

joint

to

facilitate

the

assembly

process

and

the

correct

operation

of

the

penstock

(do

not

use

oil

or

grease);

table

1

below

shows

details

of

the

petroleum

jelly

used

by

CMO:

PETROLEUM

JELLY

Saybolt

Colour

ASTM

D

‐

156

15

Melting

point

(

º

C)

ASTM

D

‐

127

60

Viscosity

at

100

º

C

ASTM

D

‐

445

5

Penetration

25

º

C

mm./

10

ASTM

D

‐

937

165

Silicone

content

None

Pharmacopea

BP

OK

table

1

fig.

11