- 8 -

⑥

.

The second set load will be displayed on the Force Value window and the actual force value will

be shown on the Loading Rate window. Press “Enter” key when the value in the proving ring is

the same with the standard value.

⑦

.

Repeat the procedures above for the next set loads calibration After the calibration is completed,

verify the testing machine to see if it is in conformity with the requirement otherwise, re-calibrate

it.

VII.

Troubleshooting

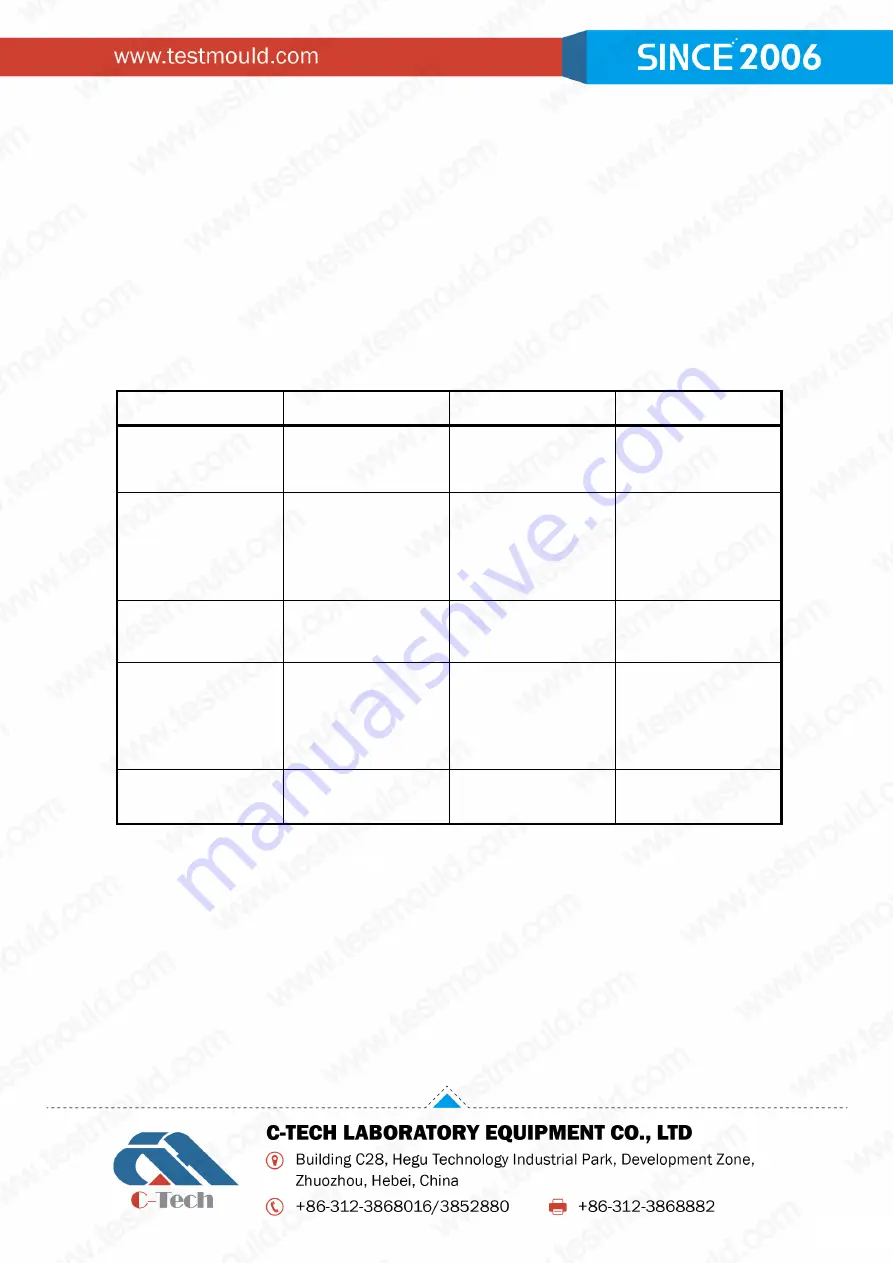

Trouble

Cause

Elimination

Remark

No display on the

windows when the

power supply is on

Fuse damaged

Check and replace the

4 fuses in the rear of

the panel

If the fuses are ok,

check if the input is

normal.

The contactor is

actuated but the

motor does not run

when the motor button

is pressed on the

panel

No power supply to the

motor

Check the wire

connection of the

motor and the socket

Check with the

Qualified electrician

No character is printed

out but the printer

works normally

The ink ribbon is dried

Replace the ink ribbon

according to

the

printer manual

“E---2 is shown on the

Loading Rate window

Transducer damaged.

Overload of the

compression testing

machine. Transducer

is not in good contact

Relief the

compression testing

machine.

Re-connect the

transducer

It can’t be reached to

the full range load

when calibration

Zero shift of the

transducer

See Self-check of the

transducer

Contact with The

manufacturer

Summary of Contents for SYE-2000BS

Page 1: ...I COMPRESSION TESTING MACHINE SYE 2000BS...

Page 11: ...9...