16

16

6

Adjustments

6.1

Vacuum Adjustments

With an under pressure (vacuum) will be the label fixed on the pad. This vacuum must be so strong that the label is

fixed on the pad and all suction holes of the pad are covered by the label. The vacuum doesn't be so strong that the

correct transport of the label from printer to applicator will be risk. This is depend of the label material.

The standard value ex factory is -0.6 bar

i

Note!

Over the adjustment of the vacuum it is possible that the form feed of the label to the pad could be

manipulate.

If the vacuum to strong it is possible that the form feed of the label stop to early.

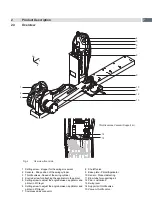

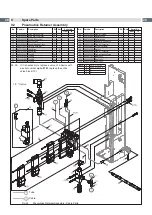

support air

vacuum

1

Fig. 11

Throttle valve "vacuum"

Adjust the vacuum on the throttle valve "vacuum" (1) so that the label will sucked on over the complete area .

To increase the vacuums turn the setting screw on the throttle valve (1) counterclockwise.

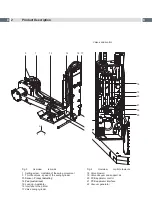

Measuring Point (MP V) to measure the Vacuums

MP V

1

2

3

MP V

Use a manometer with a measurement area -7 to 7 bar for

measurement the pressure.

MP V: Vacuum (standard value -0.6 bar)

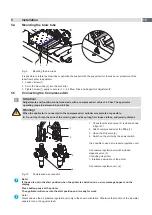

1. Remove cover.

2. Cover suction plate hermetic.

3. Attach manometer between measurement points MP V.

- Tube (1) at the energy track

- Fitting (2) on the pad

4. Activate the valve manually with open compressed air

supply and pressing of micro switch (3) to measure the

pressure.

5. As and when required adjust it on vacuum throttle valve

"vacuum".

6. Mount cover again.

Fig. 12

Measuring point to measure the vacuum

!

Attention!

After pressure measurements, connect all component exactly and check it.