23

7.3

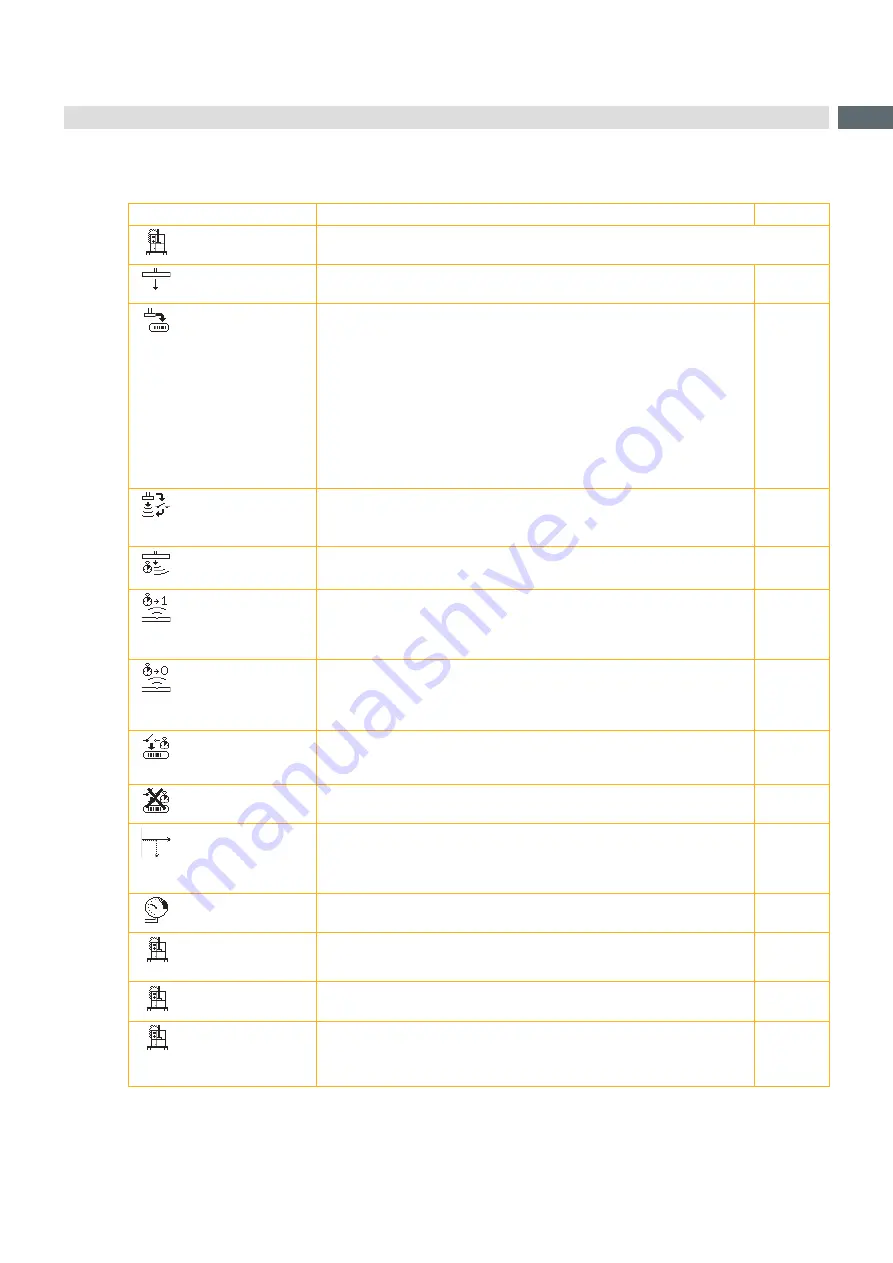

Configuration

Parameters of the Applicator

The configuration parameters of the applicator can be found in the menu

Setup > Machine param.

Parameter

Meaning

Default

Applicator

Configuration parameters of the applicator

> Mode of oper.

Setting the operation mode

Stamp on, Roll on, Blow on

Stamp on

> Mode of appl.

Setting the application mode

Print-Apply

/

Apply-Print

Print-Apply

:

An external start signal releases the print of a label and following the

application of the label. After a cycle is complete, the pad without label

waits in the start position.

Apply-Print

:

An extra signal starts the print of the first label and the transfer of the

label to the pad. The external start signal releases the application of

the label and following the print and transfer of the next label.

After a cycle is complete, the pad with a label is in the waiting position.

Print-

Apply

> Waiting position

only at Mode of oper.

Blow on

and Mode of appl.

Apply-Print

up

: Pad waits in the start position for the start signal

down

: Pad waits in the labeling position for the start signal

up

> Blow time

only at Mode of oper.

Blow on

Switch-on time (max. 2.5 s) of the blowing air for the label transfer

0 ms

> Support delay on

Setting the switch-on delay (max. 2.5 s) for the supporting air between

print start and switching on the supporting air. The delay prevents

swirling at the front of the label and, consequently, avoids faults when

the label is being picked up from the printer.

0 ms

> Support del. off

Setting the switch-off delay (max. 2.5 s) for the supporting air between

the end of label forwarding and switching on the supporting air. The

delay can be useful to separate the rear edge of the label from the

carrier to avoid errors and to improve the accuracy of label positioning

270 ms

> Delay time

Delay (max. 2.5 s) between start signal and the start of an labeling

cycle.

Allows e.g. the use of product sensors at conveyors.

0 ms

> Lock time

All start signals coming in following the first start signal are ignored

when they arrive within the lock time.

0 ms

> Peel position

Shift the position of the dispensed label relatively to the dispense

edge. In the software an extra peel offset value is available. The offset

values from “Peel position“ and from software are added together for

execution.

0.0 mm

> Vacuum control

Setting the label transfer check from printer to pad and from pad to

product by the vacuum sensor

On

> Hand-over up

Take over the label direct from the dispense edge via contact between

pad and dispense edge.

Not in function for Type 4014 / 4016, 4314 / 4316

Out

> Cleaning blow

Activate / Deactivate - air pressure impulse to clean the pad

On

> Vacuum delay

On -

The vacuum will switched on after end of the label

transport.

Out -

The vacuum will switched on with start of the label

transport.

Out

Table 5

Applicator parameters