23

6.3

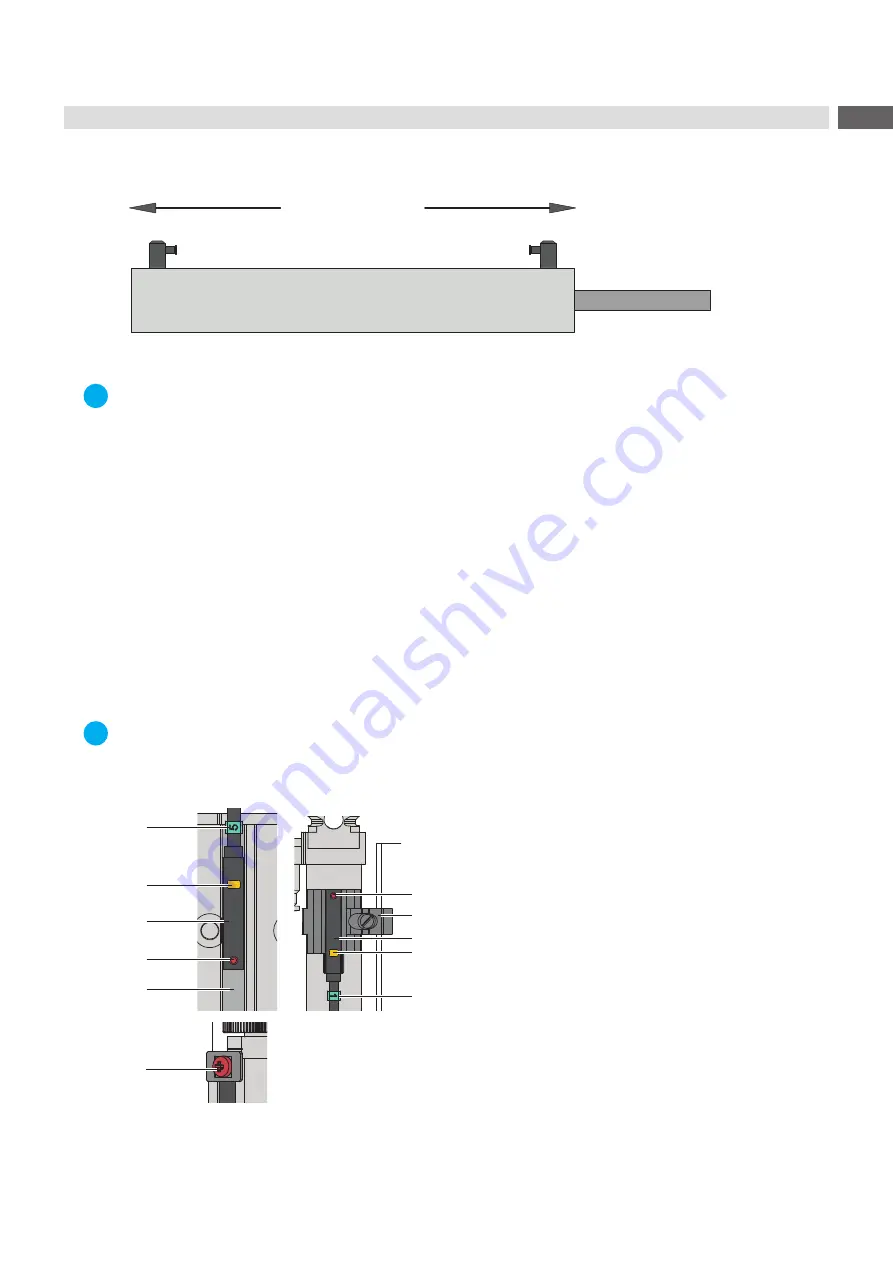

Set Throttle Valves on the Cylinders

Exhaust throttle valves are installed on the cylinders of the applicator. The valves control the movement of the

cylinders in the direction of the valves.

move in direction

of the piston

move out direction

of the piston

Fig. 20

Throttle valves on the cylinders

i

Note!

When replacing or re-adjusting the throttle valves, always adopt the settings from the test report!

The setting values are the revolutions of the adjusting screw on the throttle valve. To do this, the throttle valve is

completely closed. Turn the adjusting screw on the throttle valve clockwise until it stops.

To adjust, turn the adjusting screw on the throttle valve counterclockwise. The number of revolutions for the

respective throttle valve can be found in the test protocol included in the scope of delivery of the applicator.

•

Factory settings throttle valves

Cylinder Z

„6.7 Lift Speed of Cylinder Z“

Cylinder Y

„6.12 Lift Speed of Cylinder Y“

6.4

Set the Sensors

Sensors are used for status detection and process control on the applicator. Precise positioning is important for the

applicator to function correctly. The sensors are proximity switches that are triggered by a magnet in the cylinder

piston.

An LED is integrated for status detection of the sensor. This LED lights up when the sensor is triggered by the

magnet in the cylinder piston.

i

Note!

When replacing or re-adjusting the sensors, always adopt the settings from the test report!

Sensor and types of mounting

1

3

4

2

6

5

1

2

7

3

4

1. Sensor

2.

Set screw with 0.8 mm hexagon socket to fix the sensor.

3. LED for status detection.

4. Markers on the sensor and on the connector for

connection to the control circuit board

5. Guide groove on the cylinder.

6.

Phillips screw with holding plate for fixing the sensor.

7. Mounting clamp for sensors.

Fig. 21

Sensor / Mounting

•

Factory setting sensors

Cylinder Z

Cylinder Y

Summary of Contents for 4214 Series

Page 1: ...Service Manual 4214 MADE IN GERMANY Stroke Turn Applicator...

Page 39: ...39 9 Drawings 9 2 Pneumatic Drawing Type 4214 Fig 43 Pneumatics type 4214...

Page 40: ...40 40 9 Drawings 9 3 Labeling Position Type 4214 L Fig 44 Labeling position 4214L...

Page 41: ...41 9 Drawings 9 4 Label Position Type 4214 R Fig 45 Labeling position 4214R...