30

30

6.10

End Position Cushioning

i

Note!

The end position cushioning of the cylinder is set up to client specifications and does usually not need to be

adjusted.

2

1

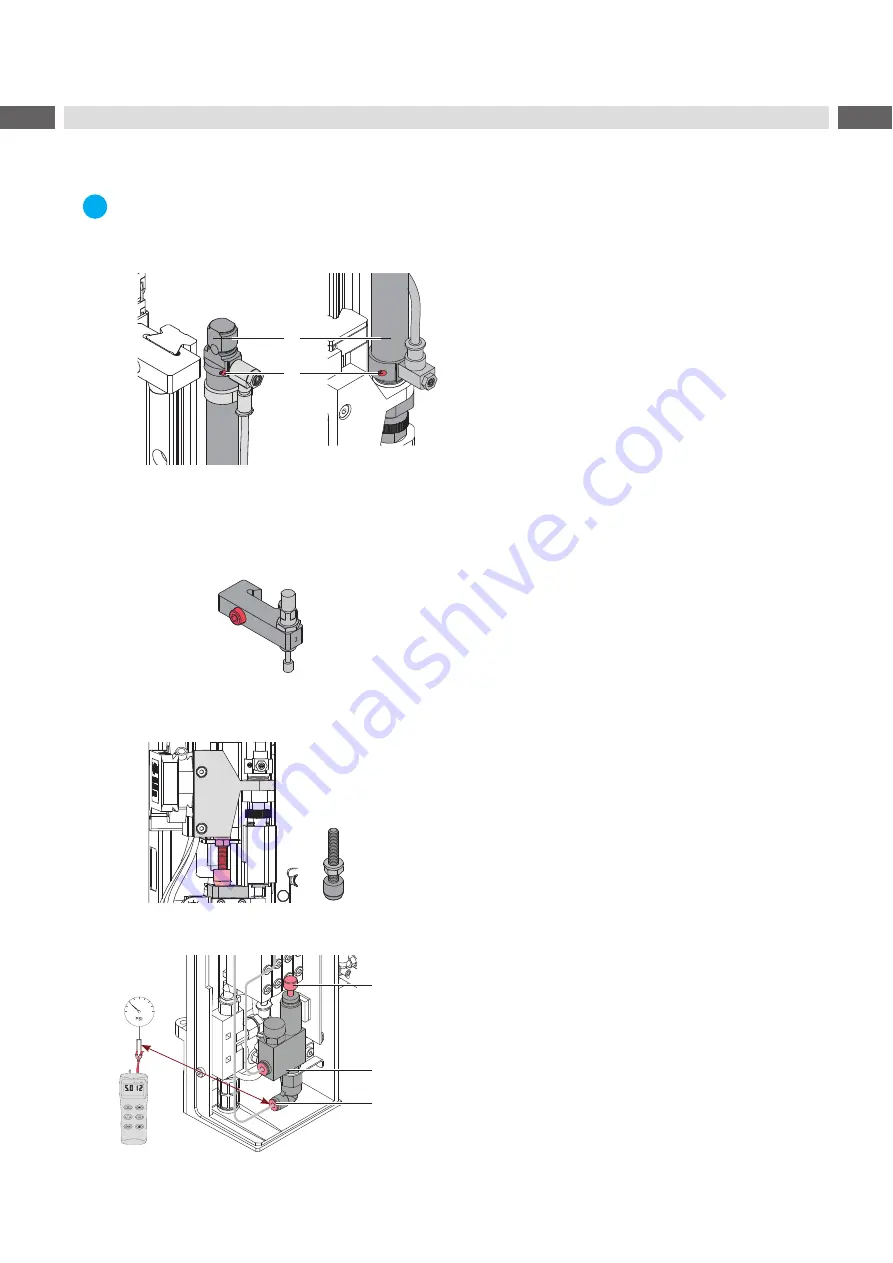

The end position cushioning of the main cylinder reduces

the impact energy when the applicator is operating at high

speeds and/or masses.

Adjust the end position cushioning so that the piston arrives

the end position definitively but does not strike it to hard.

A higher level of end position cushioning will reduce the lift

speed.

To increase the value of the end position cushioning turn

the setting screw (2) clockwise on cylinder (1).

To reduce the value of the end position cushioning turn

the setting screw (2) counterclockwise on cylinder (1).

Fig. 31

End position cushioning

6.11

Adjusting the Options for Z-Direction Movement

Fig. 32

Stopper with cushioning (Guide Rail)

The stopper with cushioning (guide rail) reduces the speed

of the cylinder Z shortly before impact when the applicator is

operated at higher speeds and/or with larger pads.

Adjustments like chapter

„6.7 Adjustment of the Stopper for

Adjust the stopper with maximum compressed spring.

Fig. 33

Stopper (pad assembly)

The stopper avoids the triggering of the labelling sensor by

the weight of the pad assembly during the inward motion of

an installation turned 90° or 180°.

The setting occurs during the take-up of the label from the

printer.

1. Loosen the counter nut of the stopper.

2. Turn the stopper until it touches the pad retainer lightly.

Do not change the take over position of the pad by via

stopper.

3.

Tighten the counter nut to fix the stopper.

3

2

1

MP S

1

2

3

Fig. 34

Pressure reduction valve

cylinder Z

The pressure reduction valve (2) can be used when labelling

pressure-sensitive products or considering general safety

aspects to reduce the pressure of the cylinder in Z-direction.

The standard value is 2.5 bar.

Connect the manometer between tube and exit (3) and

adjust the pressure to 2.5 bar with the knurled screw (1).

It is possible to order an upgraded set with a pressure

reduction valve.

Instructions are provided with the upgraded set.

Summary of Contents for 4214 Series

Page 1: ...Service Manual 4214 MADE IN GERMANY Stroke Turn Applicator...

Page 39: ...39 9 Drawings 9 2 Pneumatic Drawing Type 4214 Fig 43 Pneumatics type 4214...

Page 40: ...40 40 9 Drawings 9 3 Labeling Position Type 4214 L Fig 44 Labeling position 4214L...

Page 41: ...41 9 Drawings 9 4 Label Position Type 4214 R Fig 45 Labeling position 4214R...