12

13

4

Adjustments

Note!

The alignment of the applicator to the printer is fixed according to factory standards and should not be

altered to ensure a safe label application. Only the angle to the printer may be changed.

4.1

Setting the Angle to the Printer

1

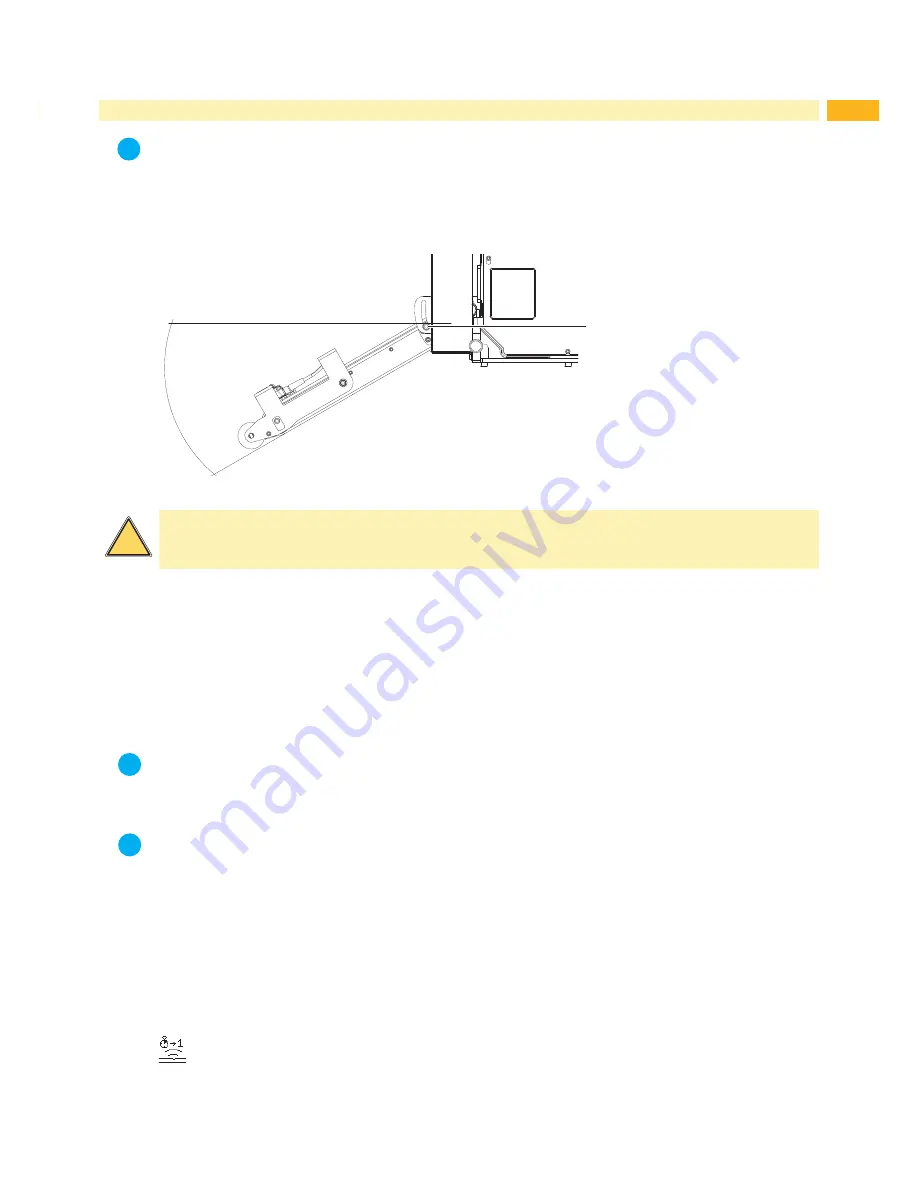

max 30°

Fig.9

Setting the angle to the printer

Warning!

Take care when loosening screw (1). The device drops due to its own weight.

Loosen screws (1) to adjust the angle and thus the depth of the applicator to the printer.

Set the angle or depth of the product and tighten the screws (1).

4.2 Adjust the Setup of the Printer

4.2

Adjusting the Setup of the Printer

The configuration parameters of the applicator can be found in the menu

Setup > Machine param.

Speed

Note!

The speed of the belt and the label transportation will set by the parameter

Support del. OFF

.

The value is displayed in ms and not in real value used mm/s.

Note!

It's necessary to set exact the values in the table.

Deviations will result in automatic defaulting back to the standard value of 100.

Parameter to set the speed of the belts.

Four steps are available.

100 ms : 100 mm/s speed of the transportation belt

150 ms : 150 mm/s speed of the transportation belt

220 ms : 220 mm/s speed of the transportation belt

300 ms : 300 mm/s speed of the transportation belt

500 ms : 500 mm/s speed of the transportation belt

> Support del. OFF

i

i

i

!