16

17

6.2

Settings in the Configuration of the Printer

3

2

1

4

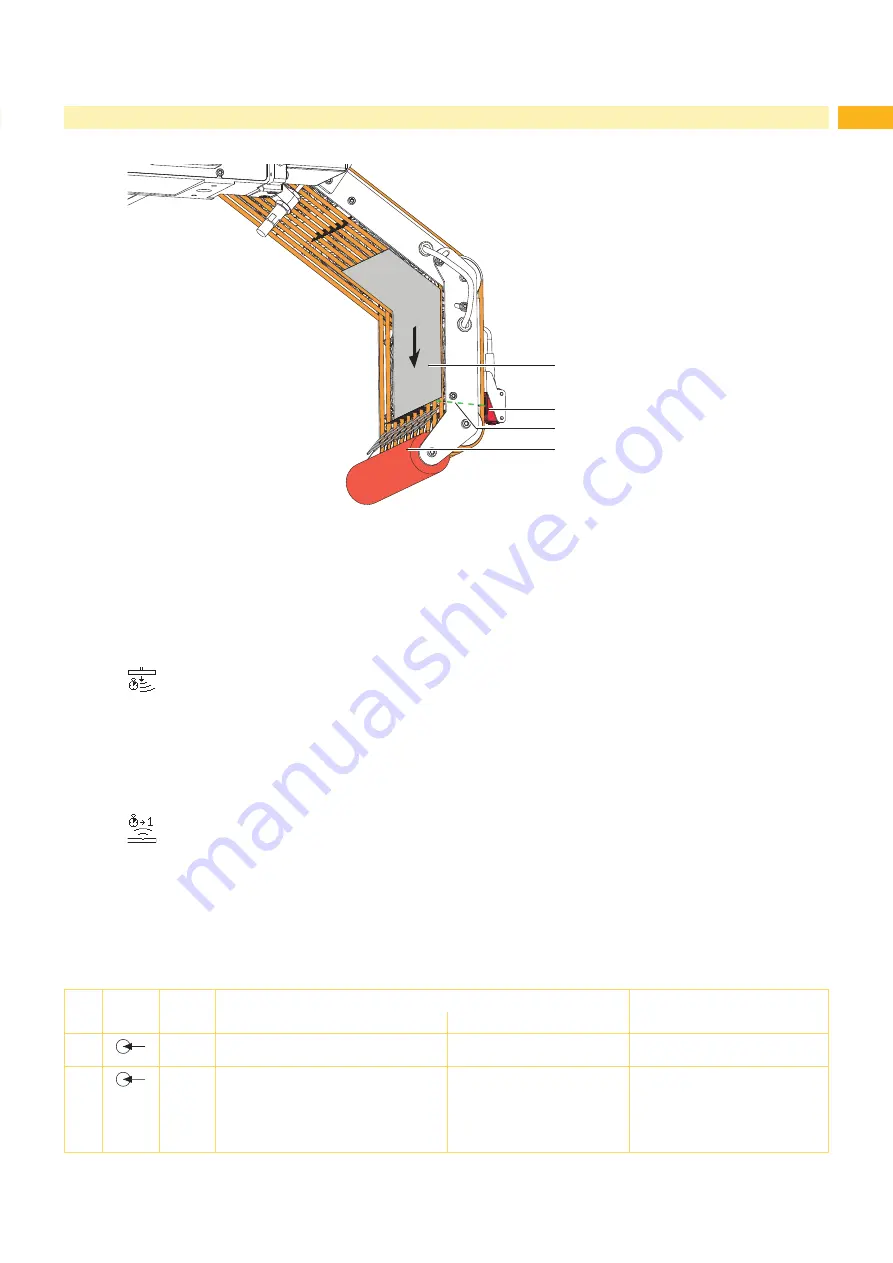

Fig. 11

Label transport/reflex sensor

Waiting position of the label

The operation mode

"Blow"

must be selected in the setup. Only once this is selected is it possible to change the

parameter

"Blow time"

.

After detection of the label (1) by the reflex sensor (2) it will be transported further for a set time to reach the pinch

roller (4).

To change this value use the parameter:

> Blow time

A higher value causes a longer transport distance.

200 ms equates to approximately 10 mm.

„7.2 Configuration Parameters of the Applicator“

Overrun of the label

If the label (1) has left the sensor area (3) it will be transported for a defined time to apply the label via the roller. To

change this overrun time use the parameter:

> Support delay on

6.3

Signals

•

The signal

DREE

causes the label to be printed which is then transported to the waiting position.

•

The signal

START

will transport and apply the label to the product.

In the application mode

"Apply - Print"

the printing of the next label starts directly after application of the previous

label.

In the application mode

"Print - Apply"

the signal DREE must be sent for the print of each label.

Pin

Signal

Name

Description

Activation/active status

without applicator

with applicator

1

DREE

-

print first label in mode

"Apply-Print"

Switch on +24V between

Pin 1 and Pin 25

13

START

Print start signal

Precondition: The superior control

has confirmed with the ETE signal

that the previous label has been

taken from the peel-off position.

Start of printing and labeling +24V between Pin 13 and Pin

25

Table 4

A section of the

interface description of the label printer