24

24

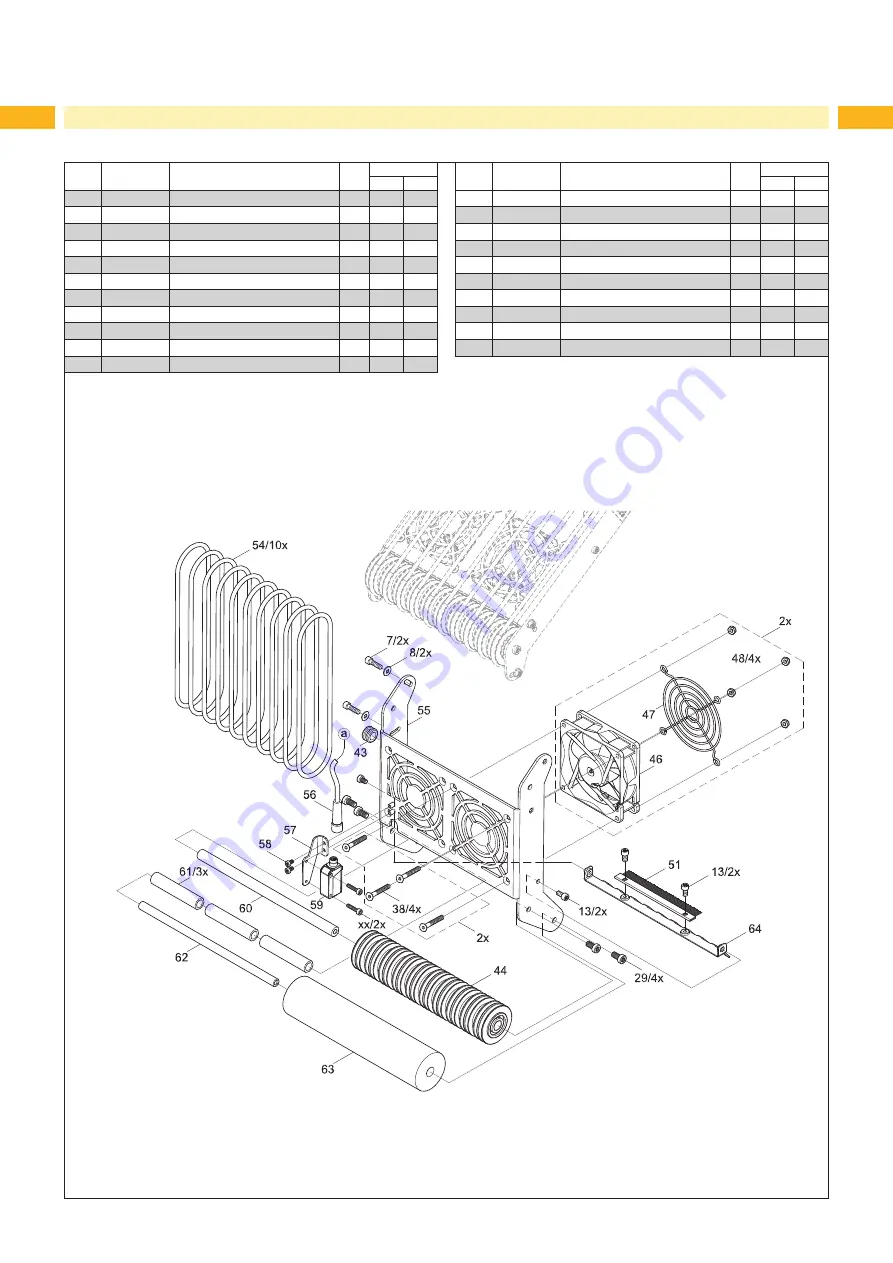

10.3

Vacuum-belt Section 2

Fig. 16

Vacuum-belt section 2 - spare parts

No.

Part No.

Description

PU

Serial No.

from

to

7

5902565.001 Screw DIN7984-M4x10

10

8

5903033.001 Washer DIN125-A4.3

10

13

5902571.001 Screw DIN7984-M4x6

10

29

5902910.001 Screw DIN7984 M5x10

10

38

5902015.001 Screw DIN7991-M4x35

10

43

5905271.001 Grommet 8x3

10

44

5972593.001

Profile Axle

1

46

5972173.001 Fan

1

47

5906299.001 Fan Grid 80x80mm

1

51

5961638.001 Antistatic Brush

1

54

5907406.001 Circular Belt 4,0x401-V

10

No.

Part No.

Description

PU

Serial No.

from

to

55

5972584.001 Base Plate

1

56

5971518.001 Cable Sensor

1

57

5972733.001 Holder

1

58

5902896.001 Screw DIN7984 M3x5

10

59

5918793.001 Sensor

1

60

5972588.001 Axle

1

61

5972414.001 Bushing

1

62

5972891.001 Axle

1

63

5972415.001 Foam Roll

1

64

5972908.001

Deflector

1