13

4

Printer Configuration

i

Note!

The values of the setup are basic settings for the current printer/cutter

combination.

After changing the cutter or printer a re-adjustment may be necessary.

Changes required for processing different print jobs should be imple-

mented by additional offsets available in the software.

The offset values from setup and software are added together for

execution.

For detailed instructions for configuration

Configuration Manual of the printer.

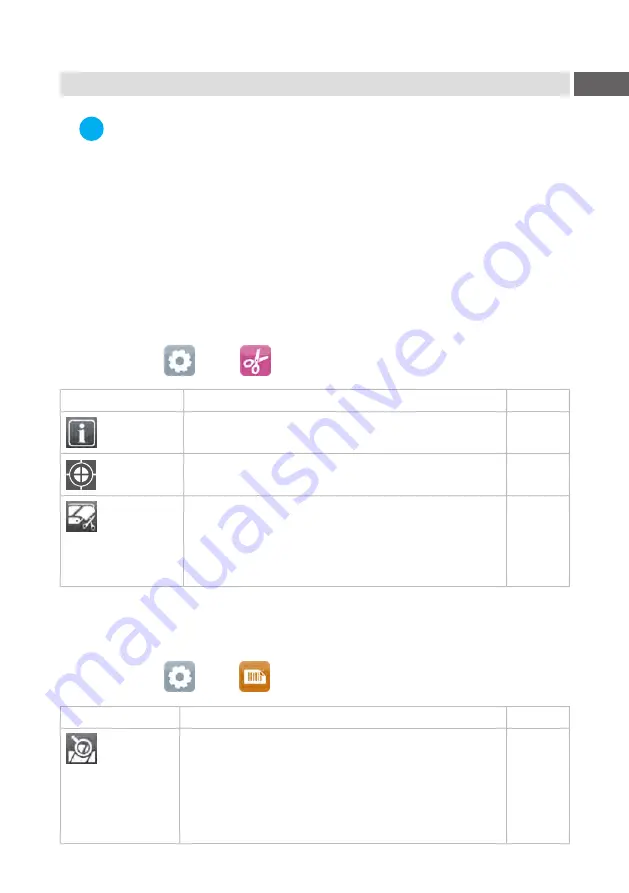

Cut Parameters

Start menu.

Select

Setup >

Cutting.

Parameter

Meaning

Default

Device info

Information to the device:

Software version, counts of cuts and errors

Calibrate

device

Calibration of the lower blade end position.

Cut position

Offset of the cut position relative to the rear label

edge.

The setting can also be adjusted by the software.

The settings of configuration

and software are

added together.

0.0 mm

Label Sensor

Start menu.

Select

Setup >

Labels.

Parameter

Meaning

Default

Label sensor

Method for detecting the starting end of the label.

Gap Sensor

: Detection using changes in the trans-

parency between the label and label gap.

Bottom-Reflect

: Detection using reflex marks on the

bottom of the medium.

Continuous media

: Checking the existence of media only.

Gap

sensor