4

5

1.3

Safety Instruction

!

Attention!

Initiation, adjustments and changing of parts is only for qualified service personal only.

Initiation/ Service Manual Applicators

• Do not use the device close to high-voltage power lines.

• Perform only those actions described in this operating manual.

Work going beyond this may only be performed by trained personnel or service technicians.

• Mind to a standing place with a flat and hard ground.

• Do not load over the maximum load of 50 kg.

• Always have service work done in a qualified workshop, where the personnel have the technical knowledge and

tools required to do the necessary work.

• In case of loosening the Flanged joint, secure the printer with help of a second person.

1.4

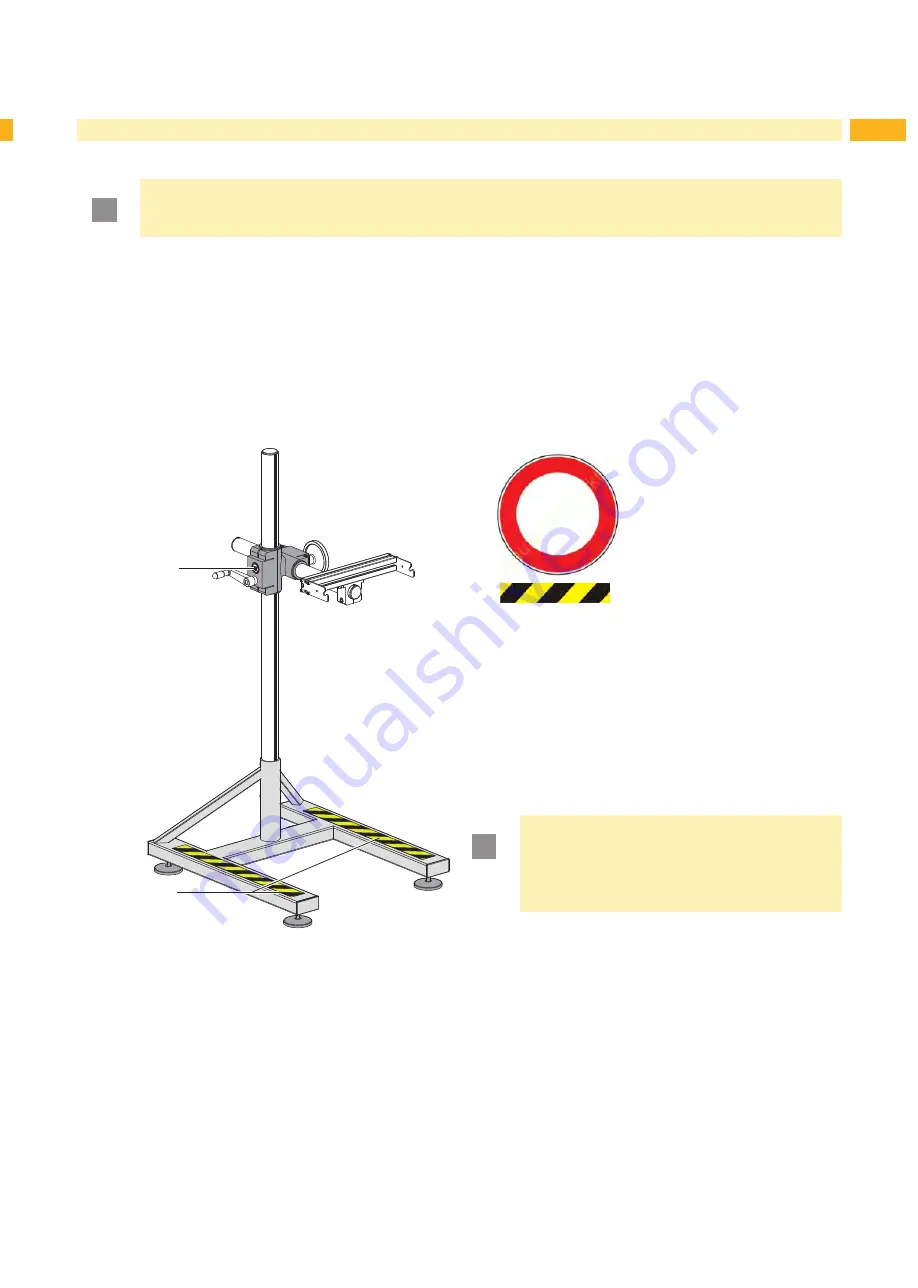

Safety Marking

1

2

1:

max. 50kg

maximum load 50 kg

2:

Signal cover yellow/black

Trip hazard!

!

Attention!

Never remove or cover safety markings!

Replace it in case of damage!

Fig. 1

Safety marking

1.5

Environment

Obsolete devices contain valuable recyclable materials that should be sent for recycling.

Send to suitable collection points, separately from residual waste.

The modular construction of the print module enables it to be easily disassembled into its component parts.

Send the parts for recycling.

1

Introduction

Summary of Contents for Hermes+ 1602

Page 1: ...Floor Stand Operator s Manual 1602 Hermes ...

Page 12: ...12 12 ...