24

24

5.4

Adjusting the Printing Mechanism

Major adjustment of the printing mechanism beyond format-based settings is only required if the printhead assembly

has been removed or parts in this area have been replaced. Excluded from this is the replacement of the printhead,

after which readjustment is generally not required.

The following print quality imperfections may indicate maladjustment of the printing mechanism:

•

Print image too light

•

Print image is spotty

•

Print image lighter on one side

•

Horizontal lines not parallel to the horizontal label edges

•

Clear lateral drift of the transfer ribbon

i

Notice!

Print image errors can also arise from wrinkling of the transfer ribbon. This is why you should check the

transfer ribbon feed path and the head locking system for correct adjustment before making adjustments to

the printing mechanism

Operator's Manual.

i

Notice!

The adjustment at both print units can be done in the same manner.

Adjustment of the printing mechanism comprises the following procedures in the order specified:

1. Prepare the label printer for adjustment

2. Adjust the position of the printhead

3. Adjust the printhead pressure

4. Adjust the transfer ribbon feed path

5.

Perform a final test

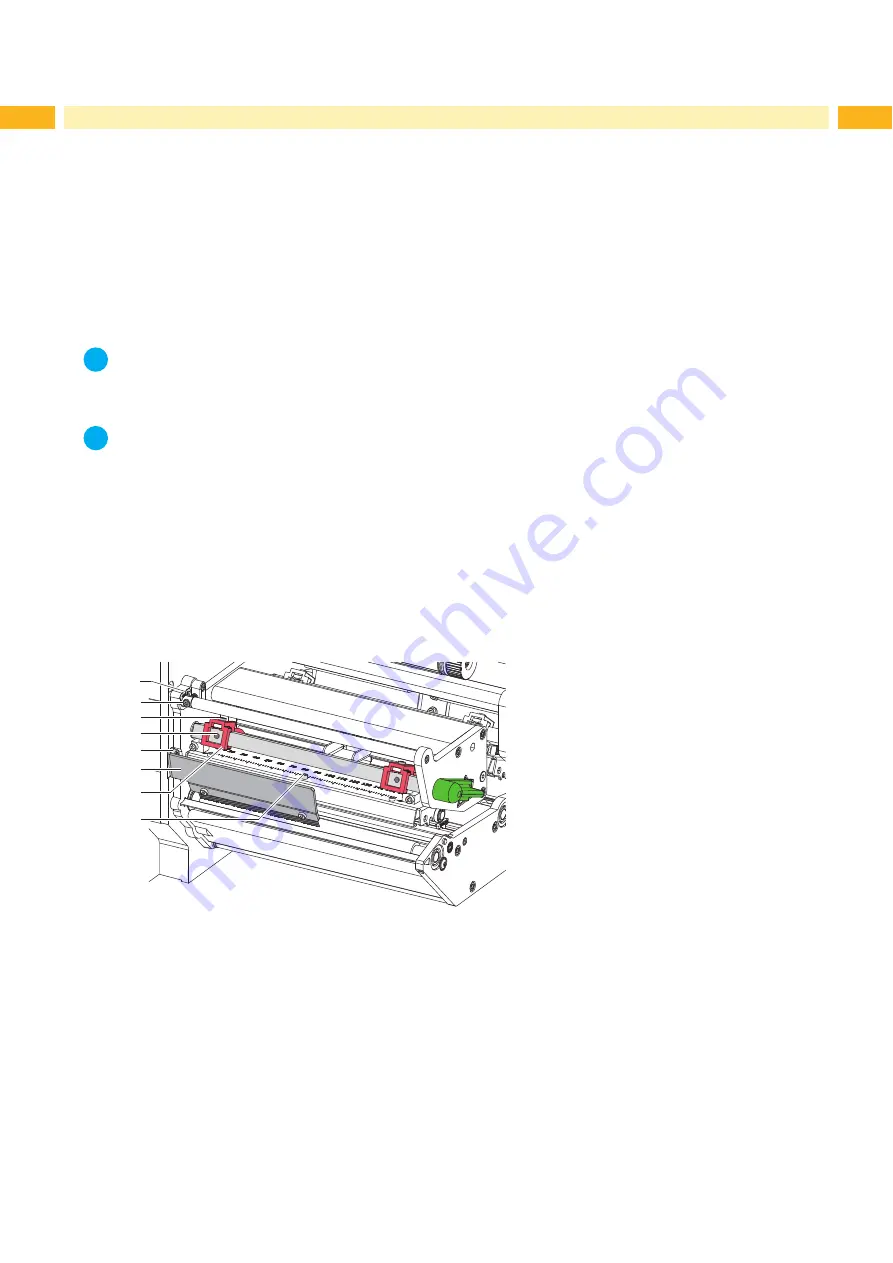

5.4.1

Preparing the Printer for Adjustment

1

2

3

4

5

6

8

7

Figure 25 Preparing the printer for adjustment

1. Check the setting of the ribbon savers

2. Load transfer ribbon at the print unit to be adjusted and labels which extend across the entire printing width.

3.

In the printer configuration, set the

Heat level

parameter to -5 and the

Print speed

parameter to 100 mm/s.

4. Loosen the screw (5) and remove the antistatic brush (6).

5.

Move the transfer ribbon deflection to the central position (1) with the screw (2).

6. Loosen screws (3) and position the plungers (7) in such a way that the adjustment screws are accessible through

the holes (4) of the square axis.

7. Loosen the screw (8) for the printhead bowing with an Allen key (1.5 mm) and turn it counterclockwise until turning

becomes perceptibly easier. This should occur after a maximum of a half a rotation.

8. Continue with the adjustment of the printhead position

Summary of Contents for Hermes C 6L

Page 1: ...Made in Germany Service Manual Hermes C Label Printer ...

Page 33: ...33 7 Block Diagram Figure 34 Block diagram Hermes C ...

Page 34: ...34 34 8 Layout Diagram CPU Figure 35 Layout diagram PCB CPU components side ...

Page 35: ...35 Figure 36 Layout diagram PCB CPU soldering side 8 Layout Diagram CPU ...