18

18

5

Adjustments

5.1

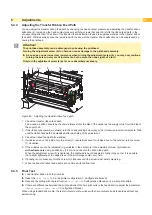

Measuring and Adjusting the Winding Torques

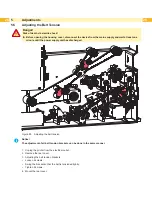

The rewinders for the transfer ribbon and the internal rewinder are coupled with slipping clutches to the rewinder

drive. The unwinders of the transfer ribbon are braked with slipping clutches during printing.

The correct setting of the torques of these slipping clutches is necessary for:

•

precise conveyance of the transfer ribbon during label transport

•

the prevention of wrinkles in the feed path of the transfer ribbon

•

high positioning accuracy of the peeled labels.

The winding axes of the rewinders are not actively driven by the belts during label backfeed, but rather solely by the

pull of the print roller. The torque required to disengage the rewinder from the belt drive is implemented via a brake

in the winding reel, which works in both directions. The measured clockwise torque is the sum of the coupling torque

and the torque of the brake. Only the torque of the brake is measured when the winding axis is rotating counter-

clockwise. For this reason, measurement of the torques at the rewinders are required in both directions.

The method of measurement differs for the various types of slipping clutches:

•

Measurement of the winding torques at the transfer ribbon rewinder and unwinder

•

Measurement of the winding torque at the internal rewinder

If the winding torque differs from the set value, it must be adjusted. The procedures for adjusting the winding torques

of the transfer ribbon winders and the internal rewinder are identical

5.1.1

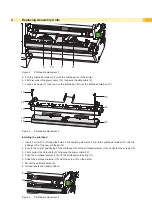

Measuring the Winding Torques

Transfer Ribbon Rewinder and Unwinder

i

Notice!

The measurement at both rewinders and unwinders can be done in the same manner.

Measurement of the winding torque at the transfer ribbon rewinder and unwinder occurs by determining the pulling

forces on a test collar attached to the winder.

The physical relation between the torque and the pulling force is:

F= M / r

F:

Pulling force [N],

M:

Winding torque [Ncm],

r:

Radius of the test collar (30 mm)

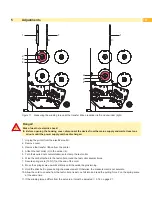

The set values for the winding torque and the resulting pulling force at the test collar are:

Slipping clutch at

Measurement

Direction of rotation

Winding torque M

Pulling force F

Ribbon rewinder

A

against winding direction

12,9 - 14,4 Ncm

4,3 - 4,8 N

B

in winding direction

2,1 - 3,0 Ncm

0,7 - 1,0 N

Ribbon unwinder

C

any

3,6 - 4,5 Ncm

1,2 - 1,5 N

Table 1

Winding torques at the transfer ribbon winders

Summary of Contents for Hermes C 6L

Page 1: ...Made in Germany Service Manual Hermes C Label Printer ...

Page 33: ...33 7 Block Diagram Figure 34 Block diagram Hermes C ...

Page 34: ...34 34 8 Layout Diagram CPU Figure 35 Layout diagram PCB CPU components side ...

Page 35: ...35 Figure 36 Layout diagram PCB CPU soldering side 8 Layout Diagram CPU ...