18

18

4.2

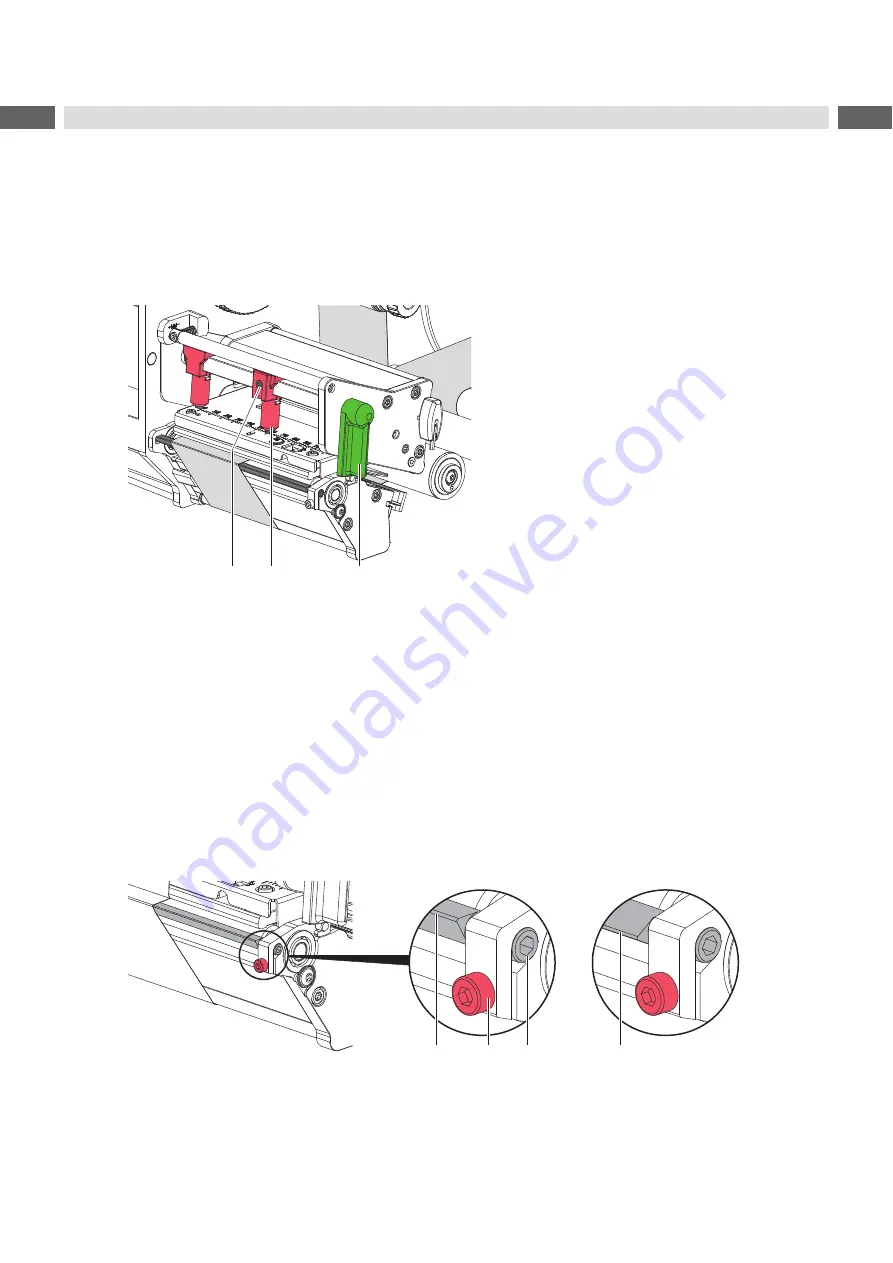

Setting the Head Locking System

The printhead is pushed on via two plungers. The location of the outer plunger (2) must be set to the width of the

label medium used so as to

•

achieve even print quality across the entire label width

•

prevent wrinkles in the feed path of the transfer ribbon

•

prevent premature wearing of the print roller and printhead.

1

3

2

Figure 16

Setting the head locking system

1. Turn the lever (3) clockwise to lock the printhead.

2. Loosen the threaded pin (1) at the outer plunger (2) with the Allen key.

3. Align the outer plunger (2) to the outer label edge and tighten the threaded pin (1).

4.3

Setting the Peel-off Edge

When operating the printer with applicator the label must be peeled-off completely from the liner for the taking over by

the applicator.

The peel-off edge can be turned to optimize especially the separation of the rear label edge from the liner.

When the printer is delivered the peel-off edge is turned in the upper end position (1a).

Depending on the used material and label size the peel-off edge can be lowered (1b).

1a

2

1b

3

Figure 17

Setting the peel-off edge

1. Loosen the screw (2).

2. Turn the peel-off edge at the hexagon (3) as necessary

3. Tighten the screw (2).

4. Test the setting.