47

cab Produkttechnik GmbH & Co KG

M4

7. Media Loading

When printing narrow label stock (width less than 60% of the maximum print

width), it is possible that the printhead will come into direct contact with the

printing roller in the area where there is no media.

CAUTION !

The printhead touching the printing roller could lead to premature failure

on the printhead or the print roller!

This can also cause the printhead to be at a slight angle to the media, leading

to a variation in the darkness of the print across the label.

This fault can be corrected by adjusting the printhead support :

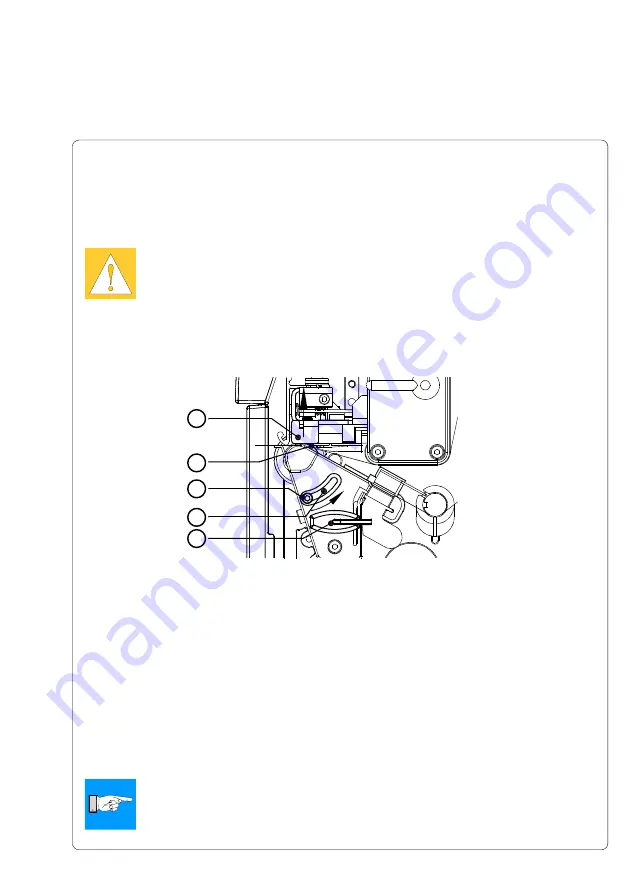

Adjustment of the Printhead Support

1. The current position of the printhead support (

2

) is shown by the position

of the screw (

3

) in the elongated hole (

4

).

2. For wide media the screw position shown in figure 7h is recommended. In

this position the printhead support (

2

) is not used.

3. For narrow media, it is necessary to adjust the printhead support. In this

case insert a second strip of a label at the outer side of the print roller and

close the printhead. Loosen the screw (

3

) using the Allen key (

5

) and slide

it slowly in the arrow direction until

the printhead support (

2

) touches the

printhead mounting (

1

).

4. Tighten the screw (

3

).

5. Remove the second label strip.

NOTICE !

Incorrect adjustments of the printhead support may cause wrinkles in the

transfer ribbon.

Fig. 7h Adjustment of the Printhead Support

1

2

3

4

5