12

!

Attention!

Decouple the carriage before move the carrige by hand . Damage the electronics!

1

2

4

5

6

2

3

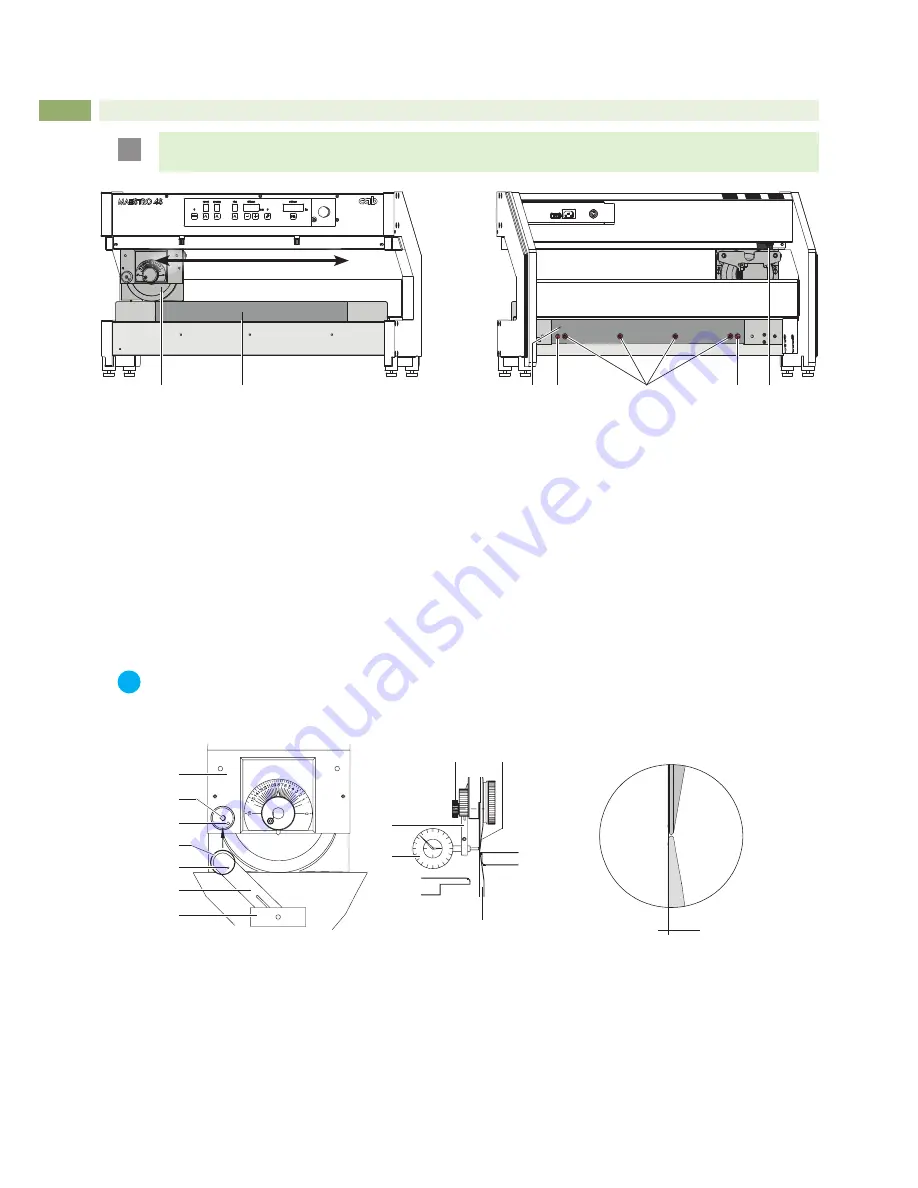

Fig.8

Setting of the linear blade (Front view)

Fig.9

Setting of the linear blade (Rear view)

1. Decouple the carriage (1) from motor by the lever (3).

2. Turn upward the upper blade by the setting knob on the carriage (1).

3. Pull the carriage (1) over the full cutting length. The Distance between upper blade and linear blade (2) must be

constant over the full length.

4. Repeat this activity with reduced distance between upper blade and linear blade (2) up to a possible variation in

the distance is visible.

5. Are variation in the distance visible, loosen screws (5) .

6. Turn the eccentric (4) to adjust the linear blade (2).The shouldered screw (6) are the axle of rotation and by

turning the eccentric (4) will the linear blade (2) lifted or put down.

7. Repeat the setting and check up to the distance is over the full cutting distance the same.

8. Tighten screws (5).

4.5

Check the Blade Alignment

i

Notice!

When the machine is put into operation for the first time, or following a move of equipment or a change of

blades, it is advantageous to re-check the alignment of the blades in relationship to one another. For this

purpose a dial gauge assembly (Part No. 8970208) is available as an option.

1

2

3

4

5

6

7

6

7

4

10

9

±

0,1

Roller Blade 8930509.001

FR4

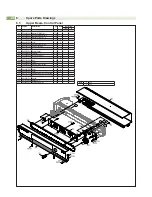

Fig.10 Check the blade alignment

1. Move the blade carrier (1) to the middle of its range of travel.

2.

Affix the dial gauge assembly onto the threaded hole (2) in the blade carrier and screw tight with the knurled

screw (4) provided. Ensure that the small spigot (5) mounted on the inside of the lever (6) locates correctly into

the hole (3) provided in the blade carrier.

3. Swing the lever (6) upwards until the tip of the gauge feeler (7) presses onto the upper blade (9) at 2 mm of the edge of

the blade. Rotate the scale on the dial gauge until the pointer in the 1/100 mm division is lined up with the „0“ on the scale.

4. Swing the lever (6) downwards until the tip of the gauge feeler (7) presses onto the lower blade (10) at 2 mm of

the edge of the blade.

5. In the event of the values obtained by the above procedure being greater than the values , the servicing agent

responsible for your machine should be contacted.

6. Remove the dial gauge assembly.

4

Test and Change Device Parts