19

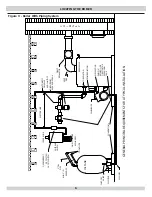

How A Hot Water System Operates

Entire heating system (boiler, piping, and radiation units)

is

fi

lled with water. As water in the boiler is heated, it

is circulated from top of boiler through supply main to

radiation units. Cooler water in radiation units

fl

ows back

through return piping through return main into the boiler.

This arrangement provides positive and rapid response to

the thermostat.

Filling The System With Water

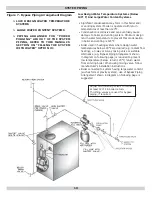

OPTION #1

This method utilizes boiler piping as shown in

fi

gure on page 6.

A. Close

main shutoff valve, isolation valves, and zone

valves (if applicable). If bypass piping is installed,

also close two throttling valves. Leave boiler service

shutoff valve (if installed) and balancing valves to

each heating zone

fully open

.

B. Open

following valves in order: drain valve for power

purging, isolating valves before and after boiler

circulator (if applicable), both throttling valves (if

applicable), and then open

fi

ll line shutoff valve. Water

will

fi

ll bypass piping and push air through piping and

out power purging drain valve. When power purging

drain valve runs air free, close bypass piping throttling

valve (leaving throttling valve to supply piping fully

open).

C. Next,

open

isolation valve (or zone valve) to

fi

rst

zone. Water will

fi

ll piping and push any air out power

purging drain valve. When power purging drain valve

runs air free, close isolation valve or zone valve).

Repeat this procedure for remaining heating zones.

D. Once all zones are

fi

lled with water and purged of air,

close

power purging drain valve and

fi

ll line shut off

valve,

open

main shutoff valve, and

adjust

throttling

valves and balancing valves as required.

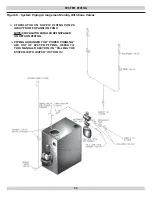

OPTION #2

• Close air vents on all radiation units.

• Open valves to radiation units. Verify boiler drain

valve, expansion tank drain cock, and air bleed screw

on expansion tank drain

fi

tting are closed.

• Open

fi

ll valve on piping to expansion tank.

• Open water inlet to boiler and leave it open.

• Open air vent on lowest radiation unit.

• When all air has escaped and water starts to

fl

ow from

vent, close it.

• Go to next radiation unit, and repeat this process until

fi

nishing with highest radiation unit.

• If heating system has automatic vents, this manual

venting is unnecessary but it will speed up proper

fi

lling

of the system.

If system is a closed expansion tank system, automatic

fi

ll

valve is needed. Leave automatic

fi

ll valve open to re

fi

ll

system automatically as needed.

Note initial

fi

ll pressure on boiler’s temperature / pressure

gauge, which should be 10-15 psig. Any lowering of

pressure from its initial

fi

ll pressure indicates loss of

water due to leakage. Automatic

fi

ll valve should then

compensate for this water pressure loss. If it does not,

manually open this valve to re

fi

ll system until needle is

again pointing to same pressure reading. Instructions are

packaged with valve.

FILLING THE BOILER

Summary of Contents for BW4BAH-91

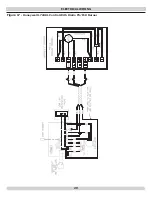

Page 22: ...22 OPERATING THE BOILER Figure 13 Burner Adjustments and Settings...

Page 28: ...28 ELECTRICAL WIRING Figure 16 Honeywell L7248L Control With Beckett AFG Burner...

Page 29: ...29 Figure 17 Honeywell L7248L Control With Riello F5 F10 Burner ELECTRICAL WIRING...

Page 31: ...NOTES...

Page 32: ...CAC BDP 7310 West Morris St Indianapolis IN 46231...