30

MAIN AIR VENT: for down fl ow systems or diaphragm

type expansion tanks (not provided)

Before system is

fi

lled with water, there is air in pipes and

radiation units. Some air will be trapped as system is

fi

lled.

It is possible to eliminate most of this air through air vents

on radiation units. Main air vent will speed and simplify this

process. Install main air vent on highest point in supply

main when all radiation is below top of boiler.

AUTOMATIC FILL VALVE (not provided)

For safe, ef

fi

cient operation, hot water system must be

fi

lled with water. Adding new water, when needed can

be done manually (by use of hand valve in water supply

line). This requires regular attention to system’s needs.

Automatic

fi

ll valve or pressure reducing valve accomplishes

this without attention. Install in supply line on hot water

boilers only. Valve operates through water pressure

differentials. It does not require electrical connection.

BURNER SOLENOID VALVE (provided)

Beckett and Carlin oil burner’s use standard solenoid valve.

Upon burner shut down, standard solenoid valve stops

fl

ow of oil to nozzle. Without solenoid valve, oil pump

continues to pump oil to burner nozzle until burner motor

winds down below pumps cutoff speed. Riello oil burner

has delay solenoid valve. Delay solenoid valve provides

same shut down action as standard solenoid valve, plus

on burner start up delay solenoid valve remains closed for

additional 15 seconds. Allows burner fan motor to pre-

purge combustion chamber and oil pump to bring supply

oil pressure up to its set point helping to provide clean light

off.

LIMIT CONTROL (provided) Refer to manufacturer

instructions provided with limit control

Water temperature limit control in limit is adjustable and

may be set: as low as 140°F so long as return water

temperatures to boiler are no less than 120°F, or as high as

220°F so long as boiler and heating system have adequate

circulation to remove heat from boiler otherwise steam may

be created in boiler. Refer back to “System Piping” section

for more information.

DRAIN VALVE (provided)

Drain valve is manually operated valve provides means of

draining all water from boiler and heating system. It should be

installed in reducing tee where return line enters boiler.

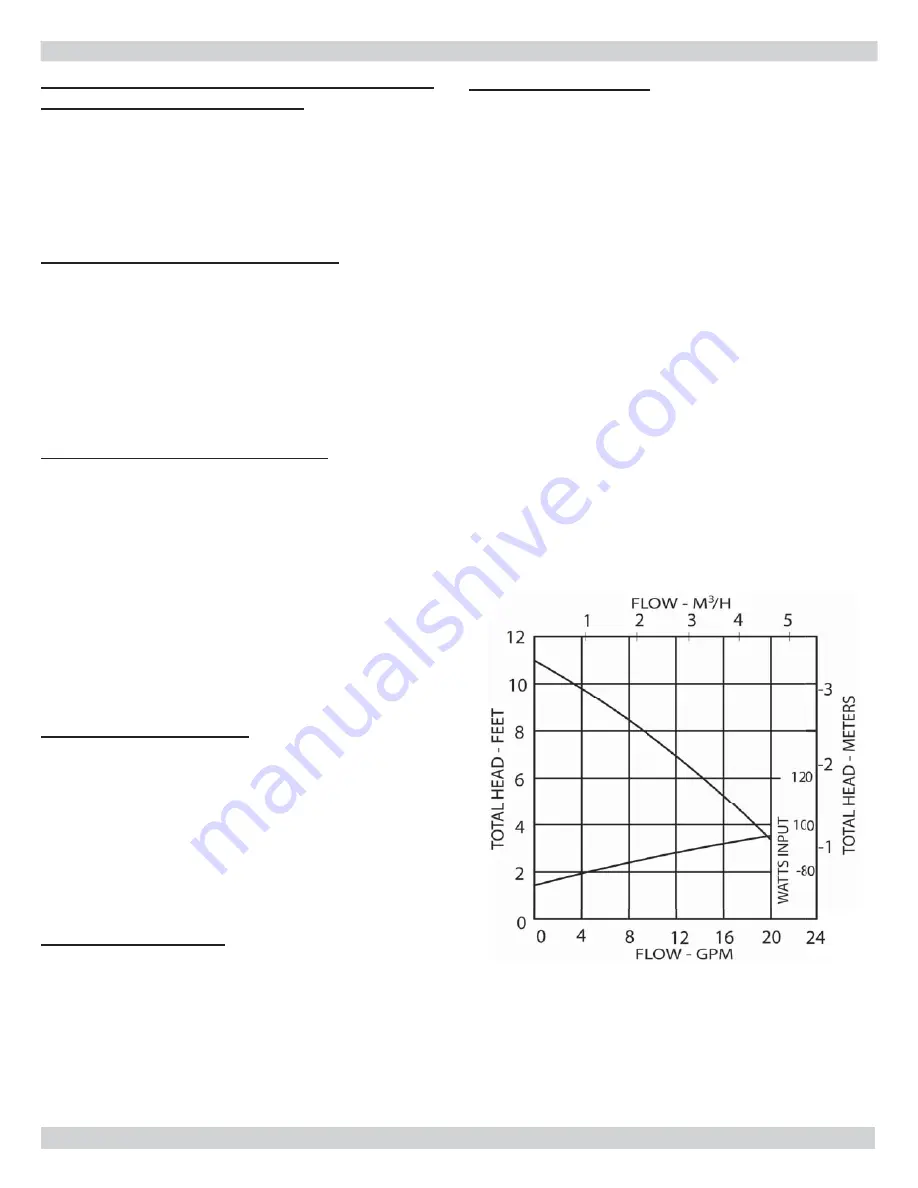

CIRCULATOR (provided)

Every forced hot water system requires circulator. Separate

circulator or zone valve is required for each zone, if there

are two or more zones. Circulator must have capacity to

provide circulation required by heating system. Circulator

should be connected to supply main and must be wired

into boiler’s electrical system. See “System Piping” section

for piping con

fi

gurations with circulator located on supply

main piping using zone circulators or zone valves. When

piping is arranged with zone circulators and no bypass

piping, circulator provided with boiler may be used as

zone circulator. Both piping arrangements allow circulator

to pump away from expansion tank and show how piping

should be arranged to allow heating system to be easily

purged of air

.

EQUIPMENT AND OPTIONAL ACCESSORIES

Taco 007 Pump Curve

Summary of Contents for BW4BAH-91

Page 22: ...22 OPERATING THE BOILER Figure 13 Burner Adjustments and Settings...

Page 28: ...28 ELECTRICAL WIRING Figure 16 Honeywell L7248L Control With Beckett AFG Burner...

Page 29: ...29 Figure 17 Honeywell L7248L Control With Riello F5 F10 Burner ELECTRICAL WIRING...

Page 31: ...NOTES...

Page 32: ...CAC BDP 7310 West Morris St Indianapolis IN 46231...