5

Complete Prior To Installing Boiler

.

A. Verify you have selected the right size boiler with

proper capacity. AHRI rating of boiler selected

should be greater than or equal to calculated peak

heating load (heat loss) for building or area(s)

served by boiler and associated hot water heating

systems. See boiler rating and capacity table

previously listed in this manual. Any heat loss

calculations used should be based on approved

methods.

B. Boiler must be supplied with proper oil supply

and oil piping, suf

fi

cient fresh combustion air, and

suitable electrical supply.

C. Boiler must be connected to suitable venting system

and piping system adequate to distribute heating

load.

D. Properly locate and install thermostat for heating

system control.

Any doubts as to requirements, check with local authorities

and obtain professional help where needed. OPERATING

INSTRUCTIONS, FINAL CHECKS AND ADJUSTMENTS, and

MAINTENANCE sections in this manual are vital to the

proper and safe operation of the heating system.

1.

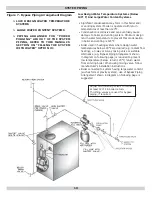

Place boiler in location centralized with the piping

system and as close to chimney as possible.

2.

Boiler must be level. If necessary use metal shims

beneath boiler’s feet.

3.

Use raised base if

fl

oor can become wet or damp.

4.

Maintain clearances for

fi

re safety as well as

servicing. 18” clearance must be maintained at

a side where passage is required for access to

another side for cleaning, servicing, inspection, or

replacement of any parts that normally may require

such attention. Boilers must be installed at least 6”

from combustible material on all sides and above.

Allow at least 24” front clearance for servicing.

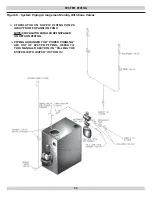

5.

Fresh air for combustion must be available at front

of the boiler. Fresh air for ventilation must be

available to front

and

rear of boiler. Air passages

must be free of obstructions at all times. Ventilating

and combustion air must enter boiler room without

restrictions.

WARNING

Fire hazard. Do not install boiler on combustible

fl

ooring or carpeting. Failure to follow these

instructions could result in death or serious injury.

!

6.

Floor supporting boiler must be noncombustible and

suf

fi

ciently stable. If it is combustible, place boiler

on 2” concrete patio blocks or 2” Cladlite Pad™.

Blocks or pad must be under entire boiler to protect

the

fl

oor.

7.

Installation shall be in accordance with the

requirements of the local authorities having

jurisdiction. Compliance with these regulations is

required. In the absence of local codes, follow NFPA

31 Installation of Oil Burning Equipment, latest

revision.

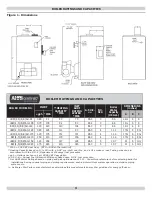

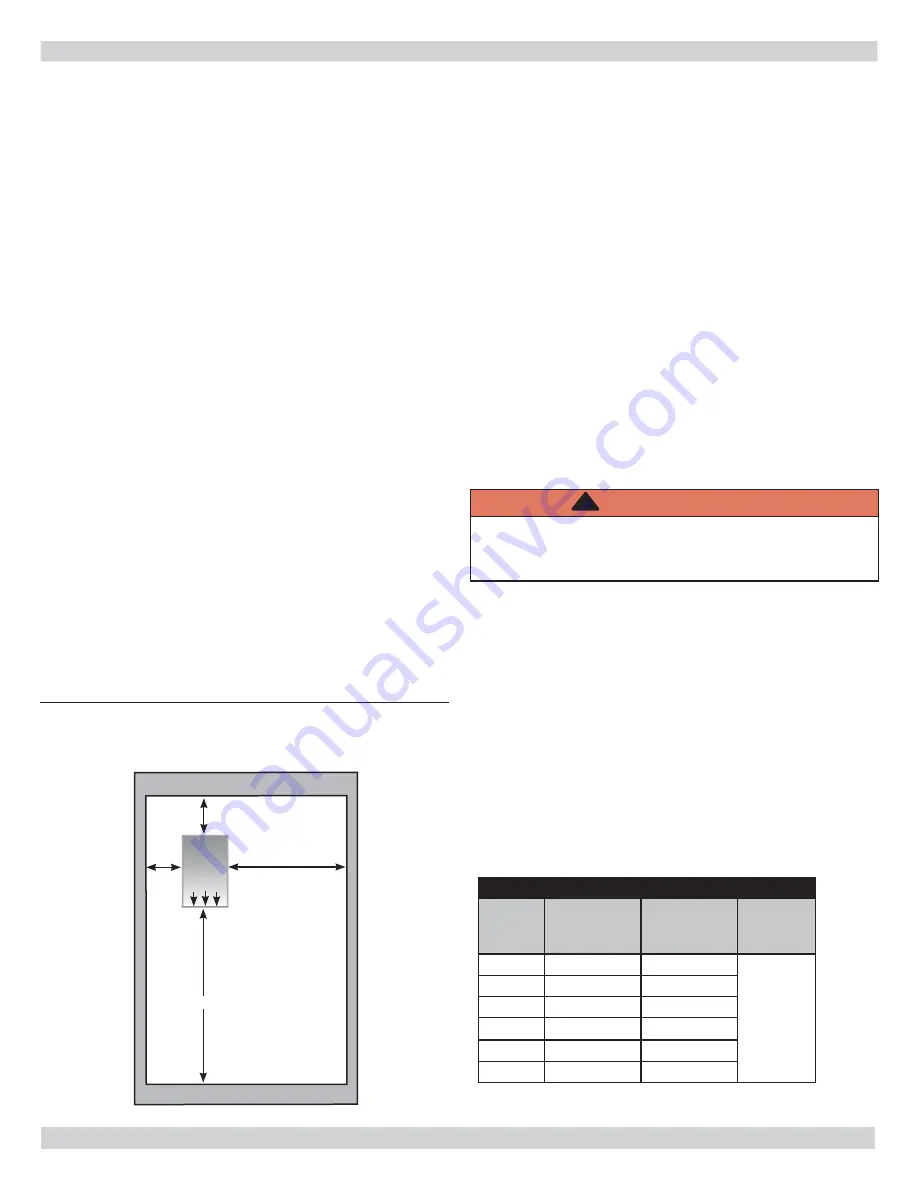

BOILER CLEARANCES

Unit

Combustible

Clearance

Accessibility,

Cleaning, and

Servicing

Flue to

Combustible

Clearance

Top

6”

18”

18”

Left Side

24”

24”

Right Side

6”

Base

non-combustible

Front

18”

Back

6”

All distances measured from the cabinet of the boiler.

24” Min.

6”

Min.

6”

Min.

6” Min./18”

With Coil

Boiler

Front

LOCATING THE BOILER

Figure 2 - Clearances

Summary of Contents for BW4BAH-91

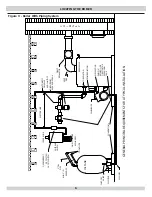

Page 22: ...22 OPERATING THE BOILER Figure 13 Burner Adjustments and Settings...

Page 28: ...28 ELECTRICAL WIRING Figure 16 Honeywell L7248L Control With Beckett AFG Burner...

Page 29: ...29 Figure 17 Honeywell L7248L Control With Riello F5 F10 Burner ELECTRICAL WIRING...

Page 31: ...NOTES...

Page 32: ...CAC BDP 7310 West Morris St Indianapolis IN 46231...