12

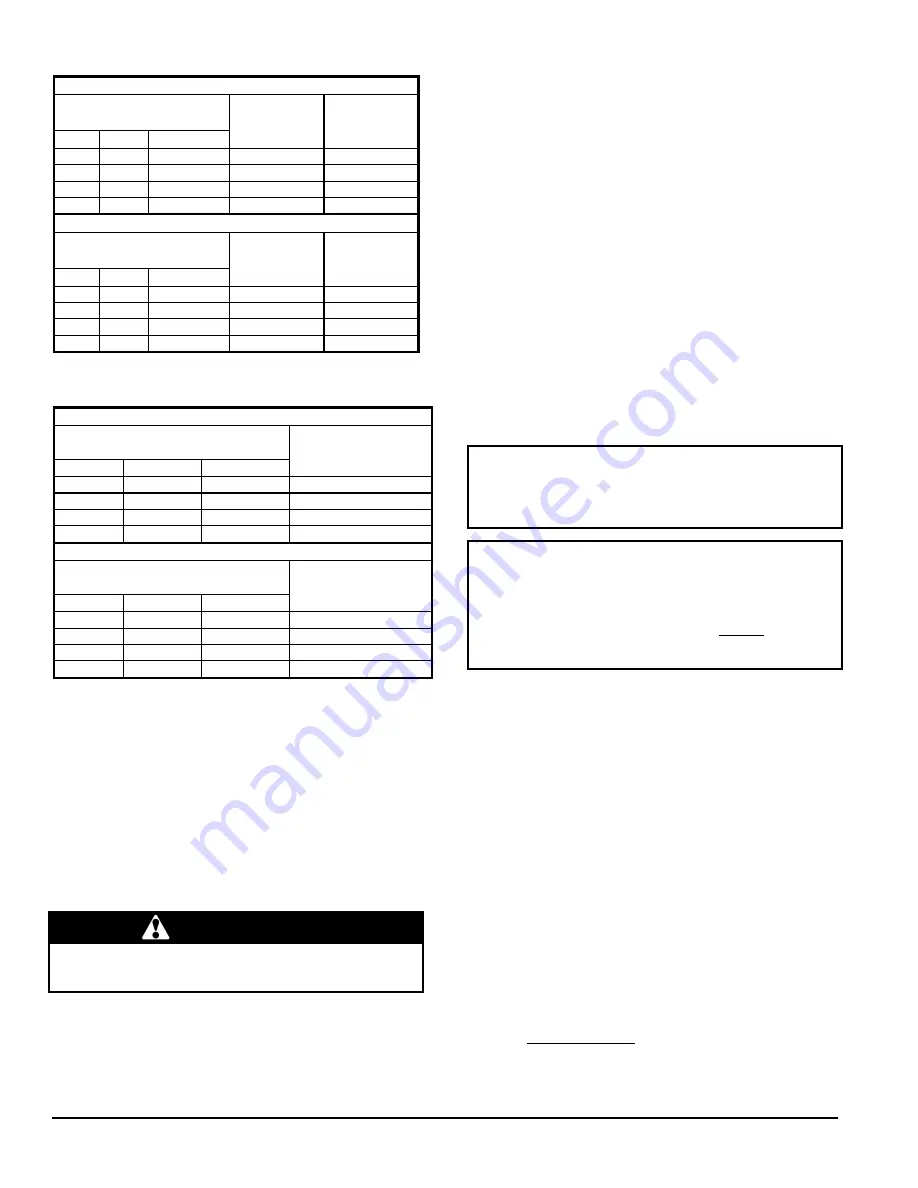

Table 5 : CFM adjustments, all modes

CVM 105

SW3 – ADJ (Adjustment)

DIP Switch Positions

1

2

POSITION

CFM HTG.

% increase

or decrease

CFM A/C

% increase

or decrease

OFF

OFF

A

0%

0%

ON

OFF

B

+10%

+10%

OFF

ON

C

-10%

-10%

ON

ON

D

N/A

0%

CVM 120

SW3 – ADJ (Adjustment)

DIP Switch Positions

1

2

POSITION

CFM HTG.

% increase

or decrease

CFM A/C

% increase

or decrease

OFF

OFF

A

0%

0%

ON

OFF

B

+10%

+10%

OFF

ON

C

-10%

-10%

ON

ON

D

N/A

0%

Table 6 : Delay adjustments, heating mode

CVM 105

SW4 – Delay

DIP Switch Positions

1

2

POSITION

Output

USGPH

OFF

OFF

A

0.75

ON

OFF

B

0.65

OFF

ON

C

0.50

ON

ON

D

ALL

CVM 120

SW4 – Delay

DIP Switch Positions

1

2

POSITION

Output

USGPH

OFF

OFF

A

0.85

ON

OFF

B

1.00

OFF

ON

C

1.10

ON

ON

D

N/A

5. The flame observation door and the two clean-out

access doors (located at the front of the unit) or well

closed;

6. The burner ‘’Reset’’ button is well pushed in or re-

armed;

7. The preliminary air adjustments on the burner comply

with the technical specifications in this manual;

8. The blower adjustments are appropriate and according

to the specifications in this manual;

9. The thermostat of the room is in the heating mode and

is set higher than the ambient temperature.

To start the unit, turn the main electrical switch on.

CAUTION

Do not tamper with the unit or its controls. Call a

qualified service technician.

3.3

PURGING THE OIL LINE

1. A 10-micron (or less) oil filter should be installed as

closely to the burner as possible with all oil burners, but

it is essential for burners with a low firing rate. We

recommend the use of a low pressure drop oil filter with

a capacity greater than that of the fuel pump;

2. On a new installation, the air trapped in the oil line

leading from the tank to the nozzle must be thoroughly

purged in order to prevent excessive after drip. The oil

pump is equipped with a special fitting that facilitates

the purging of any air between it and the tank. The

proper procedure for performing this operation is as

follows:

a. Place a piece of 1/4” diameter clear plastic tubing

over the purge fitting on the oil pump;

b. Start the oil burner, then open the purge fitting and

allow the burner to run until the purge tube is

completely free of air bubbles;

c.

At this point tighten the purge fitting, which will

allow the oil to run to the nozzle and fire the burner.

If the purging takes longer than 15 seconds and no

flame has been established the burner will stop.

Push the reset button on top of the Primary Control

to restart the burner.

For detailed information on the operation of the Primary

Control please refer to the instructions included with the

furnace or the burner.

3.4

COMBUSTION CHECK

IMPORTANT: The combustion check verification MUST be

performed after the nozzle replacement or the burner

cleaning. After these manipulations, the combustion

parameters are necessarily modified. Refer also to the

burner instruction manual.

IMPORTANT: The heat exchanger metal surfaces may

have oil and the baffle insulation also contains binders.

These products will burn or evaporate when the unit

operates for the first time. Because of this, the smoke

reading may be inexact during the first minutes of operation.

Therefore, the unit must operate during at least 60 minutes

before taking any readings to adjust the combustion quality.

Let the unit cool down before making any adjustments.

In order to obtain optimum performance from the oil burner,

the following set-up procedures must be followed by

referring to the Technical Specifications, Table 5 in this

manual:

1. A test kit to measure the smoke, flue draft and over-fire

pressure should be used in order to obtain the proper

air

band

setting. Although all of the above

measurements are required for optimum set up and

efficiency, the most important reading that must be

taken is the smoke number in the flue pipe, downstream

from the regulator;

2. The proper smoke number, as established by way of

engineering tests, is between 0 and 1. This degree of

smoke emission is commonly referred to as a “trace”. It

is recommended that a Bacharach True Spot Smoke

Test kit or equivalent be used;

3. Follow the next steps to do the combustion check

verification:

a. Drill a minimum proper diameter (about 9/32”) test

hole in the flue pipe, approximately 18 inches from

the furnace breech;

b. From a cold start, let the unit operate for about 5

minutes;

c.

Set the burner air setting until you have between 0

and 1 on the Bacharach Scale (or a “trace”);

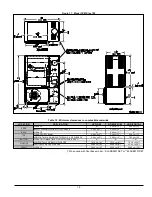

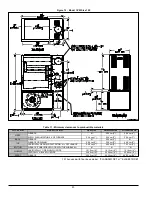

Summary of Contents for CBMAAA060120

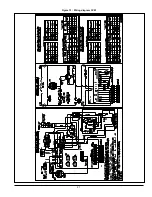

Page 21: ...21 Figure 13 Wiring diagram CVM ...

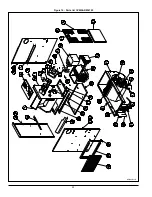

Page 22: ...22 Figure 14 Parts list CVMAAR036105 B50003 Rev D ...

Page 24: ...24 Figure 15 Parts list CVMAAR060120 B50004 Rev F ...

Page 48: ...23 Figure 13 Diagramme électrique CVM ...

Page 49: ...24 Figure 14 Liste de pièces CVMAAR036105 B50003 Rev D ...

Page 51: ...26 Figure 15 Liste de pièces CVMAAR060120 B50004 Rev F ...