sEctioN 4.4

DiaGNostic tEsts

Page 143

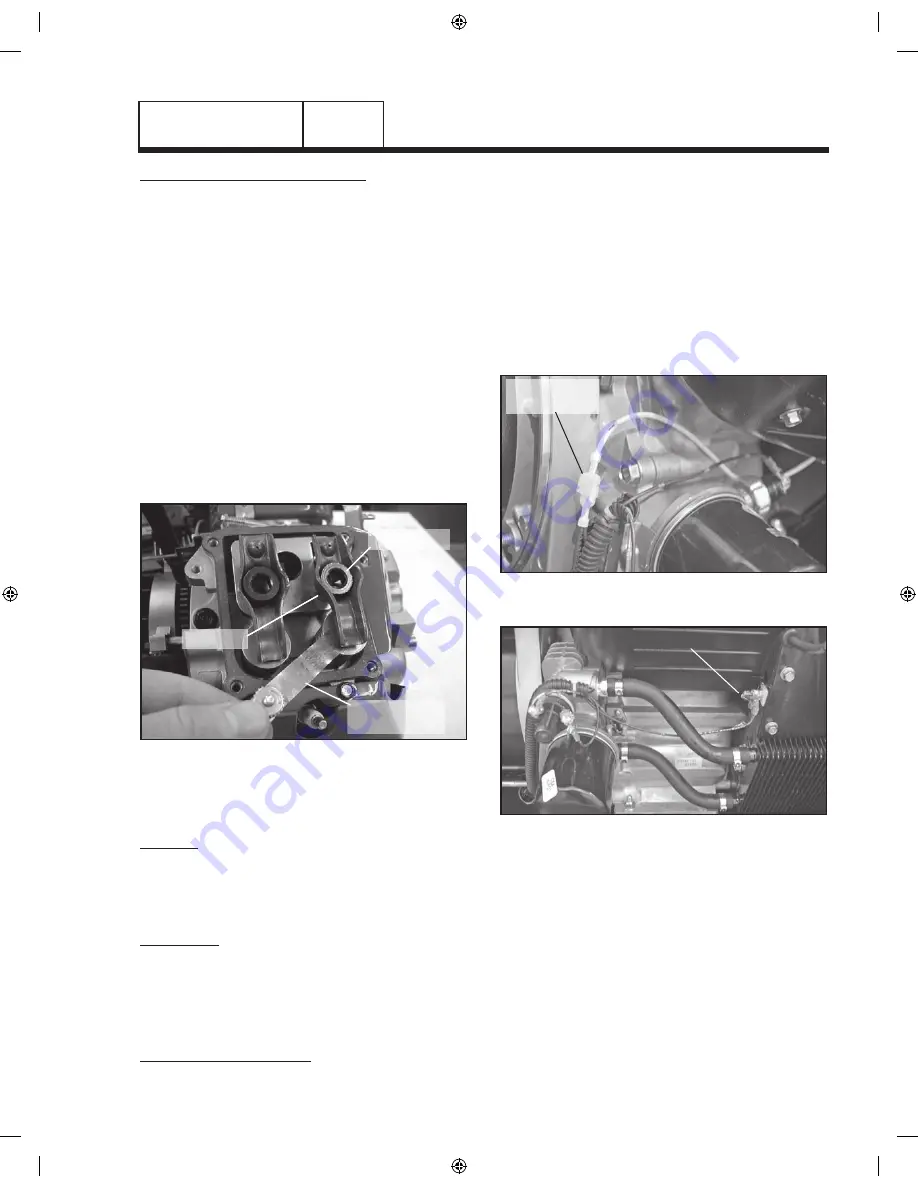

PROCEDURE: (INTAkE AND EXHAUST)

Make sure that the piston is at Top Dead Center

(TDC) of it’s compression stroke (both valves

closed). The valve clearance should be 0.05-0.1mm

(0.002-0.004 in.) cold.

Check and adjust the valve to rocker arm clearance

as follows:

1. Remove the four (4) screws from the rocker cover.

2. Remove the rocker cover and rocker cover gasket.

3. Loosen the rocker arm jam nut. Use a 10mm allen wrench

to turn the pivot ball stud and check the clearance

between the rocker arm and the valve stem with a flat

feeler gauge (see Figure 44).

4. When the valve clearance is correct, hold the pivot ball

stud with the allen wrench and tighten the rocker arm

jam nut. Torque the jam nut to 174 inch pounds. After

tightening the jam nut, recheck the valve clearance to

make sure it did not change.

0.076 mm

(0.003") SHIM

JAM NUT

BALL STUD

Figure 44

5. Re-install the rocker cover gasket, rocker cover and

the four (4) screws.

RESULTS:

Adjust valve clearance as necessary, then retest.

teSt 78 – check Wire 18 continuity

DISCUSSION:

During cranking and running the printed circuit board

receives a pulse from the ignition magnetos via Wire

18. This signal has an AC voltage of 4-6 volts on

V-Twin engines only. If this signal is not received by

the printed circuit board the unit will shut down due to

no RPM sensing.

PROCEDURE: (V-TWIN ONLY)

1. Set a VOM to measure AC voltage.

2. Connect one meter test lead to Wire 18 that is connected

to the bolt connector shown in Figure 46. Connect the

other meter test lead to a clean frame ground.

3. Set the AUTO-OFF-MANUAL switch to the MANUAL

position.

4. When the generator comes up to rated speed, measure and

record the voltage reading. 4-6 VAC should be measured.

5. If the correct voltage was not measured in Step 4, refer

back to flow chart. If the correct voltage was measured,

proceed to Step 6.

WIRE 18

CONNECTION

Figure 45. Wire 18 Connection 8 kW Units

WIRE 18 CONNECTION

Figure 46. Wire 18 Connection 10-20 kW Units

6. Set a VOM to measure resistance.

7. Disconnect the J1 Connector from the printed circuit

board.

8. Verify the continuity of Wire 18. Connect one meter

test lead to a clean frame ground. Connect the other

meter test lead to Pin Location J1-4 for all models. A

reading of 275K - 325K ohms should be measured. If

CONTINUITY is measured (0.1 ohms) a short to ground

could be present.

9. Disconnect Wire 18 from the stud connector. Continue to

leave J1 disconnected from Step 7.

DC CONTROL

Part 4

0G9266revA.indd 143

10/15/2008 11:28:22 AM