AC GENERATORS

sEctioN 2.4

DiaGNostic tEsts

Connect the other meter test lead to Wire 4 (still dis-

connected from previous tests). Measure and record

static rotor amp draw.

13. Set the AUTO-OFF-MANUAL switch to the MANUAL

position. Once the engine starts, repeat Step 12.

Measure and record running rotor amp draw with the

engine running.

14. Set the AUTO-OFF-MANUAL switch to OFF. Reconnect

Wire 4 to the voltage regulator.

RESULTS:

Refer to the chart on this page: “Results - Fixed

Excitation Test/Rotor Amp Draw Test”.

note: a calculated amp draw can be done by taking

the battery voltage that is applied divided by the

actual resistance reading of the rotor. a resistance

reading can be taken by measuring ohms between

Wires 4 and 0 at the voltage regulator.

EXAMPLE:

moDEl

5517

WIRE 2 & 6 VOLTAGE

87 VAC

WIRE 11 & 22 VOLTAGE

31 VAC

STATIC ROTOR AMP DRAW

1.0 AMP

RUNNING ROTOR AMP DRAW

1.0 AMP

These results match Column B in the chart. Refer

back to Problem 1 Flow Chart and follow Letter B.

teSt 5 – Wire continuity (12-20 kW)

DISCUSSION:

The voltage regulator receives unregulated alternating

current from the stator excitation winding, via Wires 2

and 6. It also receives voltage sensing from the sta-

tor AC power windings, via Wires 11 and 22. The

regulator rectifies the AC from the excitation winding

and based on the sensing signals, regulates the DC

current flow to the rotor. The rectified and regulated

current flow is delivered to the rotor brushes via Wires

4 (positive) and 0 (negative). This test will verify the

integrity of Wire 0.

PROCEDURE:

1. Set VOM to its “R x 1” scale.

2. Remove Wire 0 from the voltage regulator, 4th terminal

from the top. Also voltage regulator is labeled (-) next to

terminal.

3. Connect one test lead to Wire 0, connect the other test

lead to a clean frame ground. The meter should read

CONTINUITY.

RESULTS:

If CONTINUITY was not measured, repair or replace

the wire as needed.

Part 2

Page 43

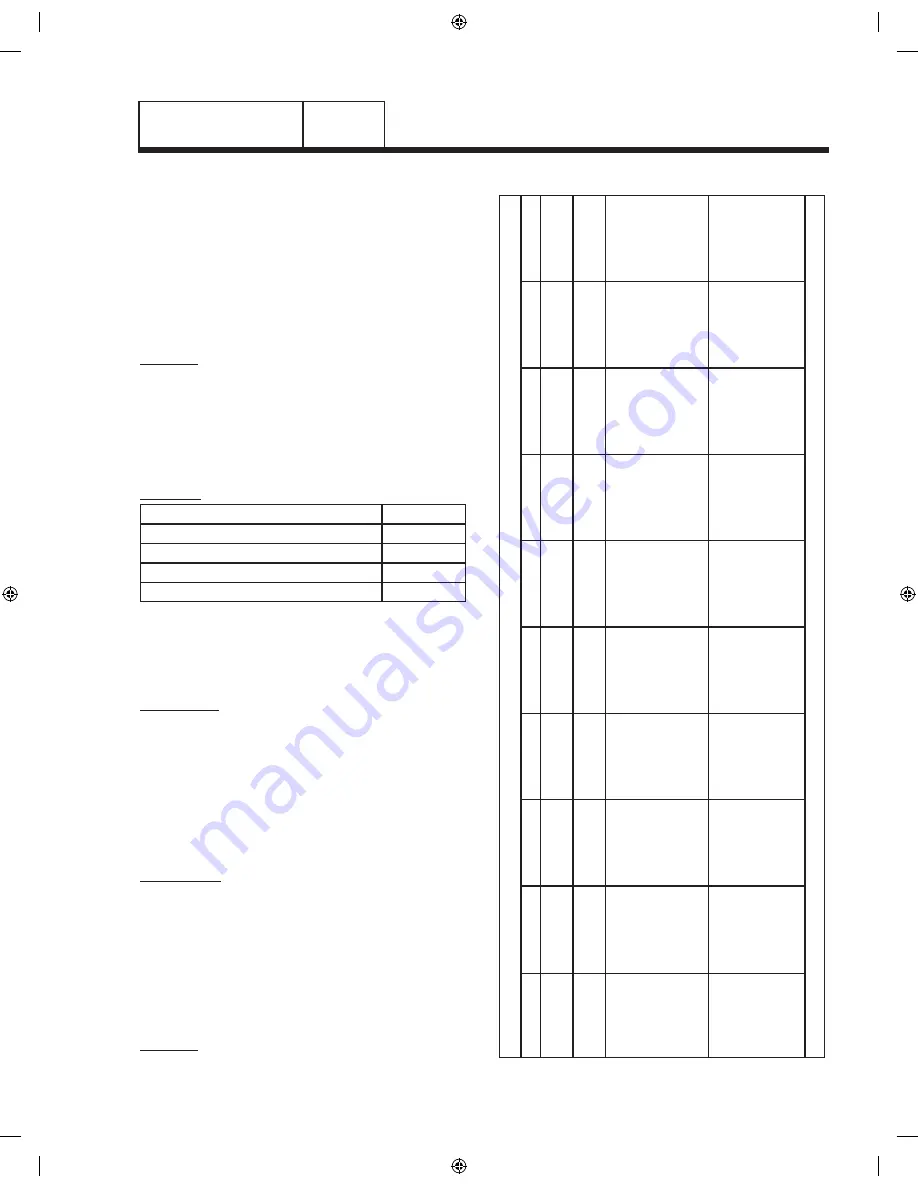

te

S

t

4

r

esults - Fix

ed

e

xcitation

t

est/

r

otor

a

mp

d

ra

w

t

est (12-20 kW)

r

esults:

(m

odel #)

a

B

c

D

E

f

G

H

V

oltage Results

Wire 2 & 6

ALL

Abo

ve 60

V

A

C

Abo

ve 60

V

A

C

Belo

w 60

V

A

C

Zero or Residual

V

olts

Belo

w 60

V

A

C

Belo

w 60

V

A

C

Abo

ve 60

V

A

C

Belo

w 60

V

A

C

V

oltage Results

Wire 11 & 22

ALL

Abo

ve 60

V

A

C

Belo

w 60

V

A

C

Abo

ve 60

V

A

C

Zero or Residual

V

olts

Belo

w 60

V

A

C

Belo

w 60

V

A

C

Abo

ve 60

V

A

C

Belo

w 60

V

A

C

Static Rotor

Amp Dr

a

w

12 kW

14 kW

16 kW

17 kW

20 kW

1.75 - 1.17

1.75 - 1.17

1.59 - 1.07

1.59 - 1.07

1.39 - 0.93

1.75 - 1.17

1.75 - 1.17

1.59 - 1.07

1.59 - 1.07

1.39 - 0.93

1.75 - 1.17

1.75 - 1.17

1.59 - 1.07

1.59 - 1.07

1.39 - 0.93

Zero

Current

D

raw

Abo

ve 2.5A

Abo

ve 2.5A

Abo

ve 2.3A

Abo

ve 2.3A

Abo

ve 2.0A

1.75 - 1.17

1.75 - 1.17

1.59 - 1.07

1.59 - 1.07

1.39 - 0.93

Zero

Current

D

raw

1.75 - 1.17

1.75 - 1.17

1.59 - 1.07

1.59 - 1.07

1.39 - 0.93

Running Rotor

Amp Dr

a

w

12 kW

14 kW

16 kW

17 kW

20 kW

1.75 - 1.17

1.75 - 1.17

1.59 - 1.07

1.59 - 1.07

1.39 - 0.93

1.75 - 1.17

1.75 - 1.17

1.59 - 1.07

1.59 - 1.07

1.39 - 0.93

1.75 - 1.17

1.75 - 1.17

1.59 - 1.07

1.59 - 1.07

1.39 - 0.93

Zero

Current

D

raw

Abo

ve 2.5A

Abo

ve 2.5A

Abo

ve 2.5A

Abo

ve 2.5A

Abo

ve 2.5A

1.75 - 1.17

1.75 - 1.17

1.59 - 1.07

1.59 - 1.07

1.39 - 0.93

Zero

Current

D

raw

Abo

ve 2.5A

ç

ma

tch re

S

ul

t

S

W

ith letter and

re

F

er

t

o

F

lo

W

char

t

in

S

ection

2.3

“

p

rob

lem 1”

è

0G9266revA.indd 43

10/15/2008 11:27:15 AM