6

6

8. Warning

•

Use an appropriate regulator that applies to SANS1537 with an outlet pressure of 2.8kPa.

•

Never disconnect the regulator while cylinder valve is open.

•

Do not change cylinders in close proximaty of open fire.

•

Do not expose your cylinder to extreme heat.

•

Do not let unauthorized persons interfere with your hob.

•

Do not cover your hob while it is still hot.

SURFACES MAY BE HOT!

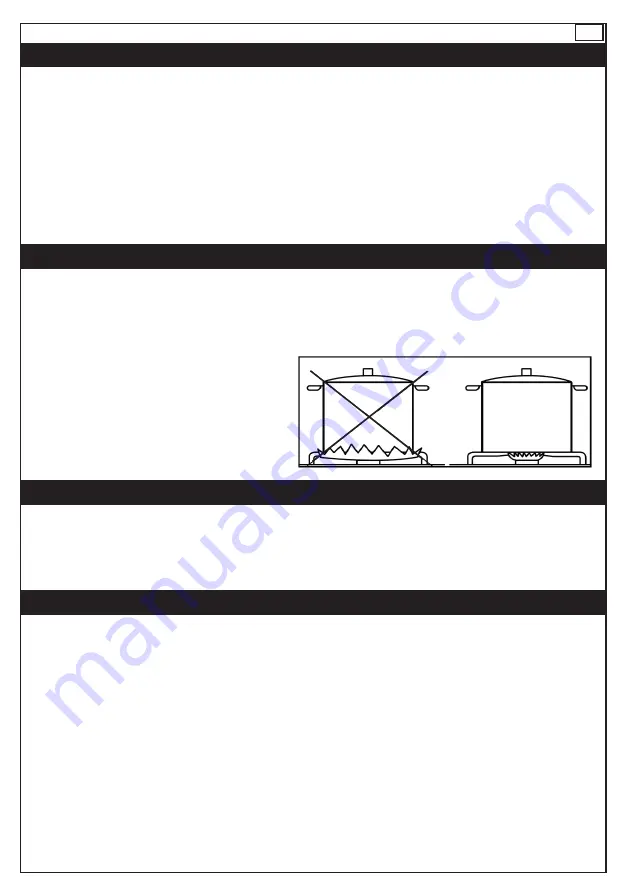

• Use a proper pot/pan size (with flat bottom only) for

each burner (see fig. below).

• When the content of the pan starts to boil, turn the

control knob down to “low flame”.

7. Fitting and Changing the Gas Cylinder

Please note! Your gas cylinder and regulator need to be fitted by the registered installer when installing your appliance for the first time.

• After use, turn off the control knob to the off position (“•” - turn fully clockwise) and close the gas cylinder valve.

• Ensure that the gas cylinder is fitted or changed in a well-ventilated location away from any source of ignition, such as naked flames

and away from other people.

• Do not smoke while changing the cylinder.

• When you need to replace your empty cylinder, make sure that the gas is closed at the cylinder valve.

Make sure that the hob burners are off and the control valves are closed.

• Remove the regulator from the empty cylinder.

• Avoid twisting the hose whilst connecting the regulator to the new/replacement cylinder.

• Blow out any dust from the cylinder opening to prevent possible blockage of the jet.

• Place the full cylinder in its allocated space and attach the regulator connection to the cylinder.

• Ensure that a complete gas seal has been made (check for the smell of gas around the connection joint). Do not check for leaks with a

naked flame. Use warm soapy water only, applied to the joints and connections of the appliance. Any leakage will show up as bubbles

around the leakage area. If you are in doubt, contact your nearest stockist.

GB

9. Cleaning

• Allow the appliance to cool down before you clean it.

• Use a damp cloth wrung out in a solution of soapy water to clean the exterior and cylinder storage area of your hob.

• Make sure that no water gets onto the burners or pilot/light area. Wipe the hob completely dry before use.

• Do not use abrasive cleaners as they may damage the surfaces.

• Clean the appliance after each use.

• Do not use any high-pressure steam equipment or a water jet to clean the appliance.

10. Maintenance

• If you clean and maintain your appliance on a regular basis, the life of you appliance will extend and possibility of problems will

decrease.

In case of a spattering flame or jet blockage:

• Clean your burner ports in case of an over spill.

• CADAC recommends to clean or replace the jets every six (6) months to ensure continued efficient operation of your appliance.

• This may be done by removing the jet using standard tools and blow any dirt from the jet, alternatively, you may purchase new jets

from your local CADAC store. Do not attempt to clean the jet mechanically.

Service intervals and servicing:

• CADAC recommends the service of your appliance to be every twelve (12) months by a service agent to ensure continued efficient

operation.

• Note: Any technical work on the appliance should only be performed by a qualified technician.

• Check your gas hose and connections regularly for and signs of leaks and every time the gas cylinder is re-filled.

Summary of Contents for 99600-42-01-ZA

Page 2: ......