17

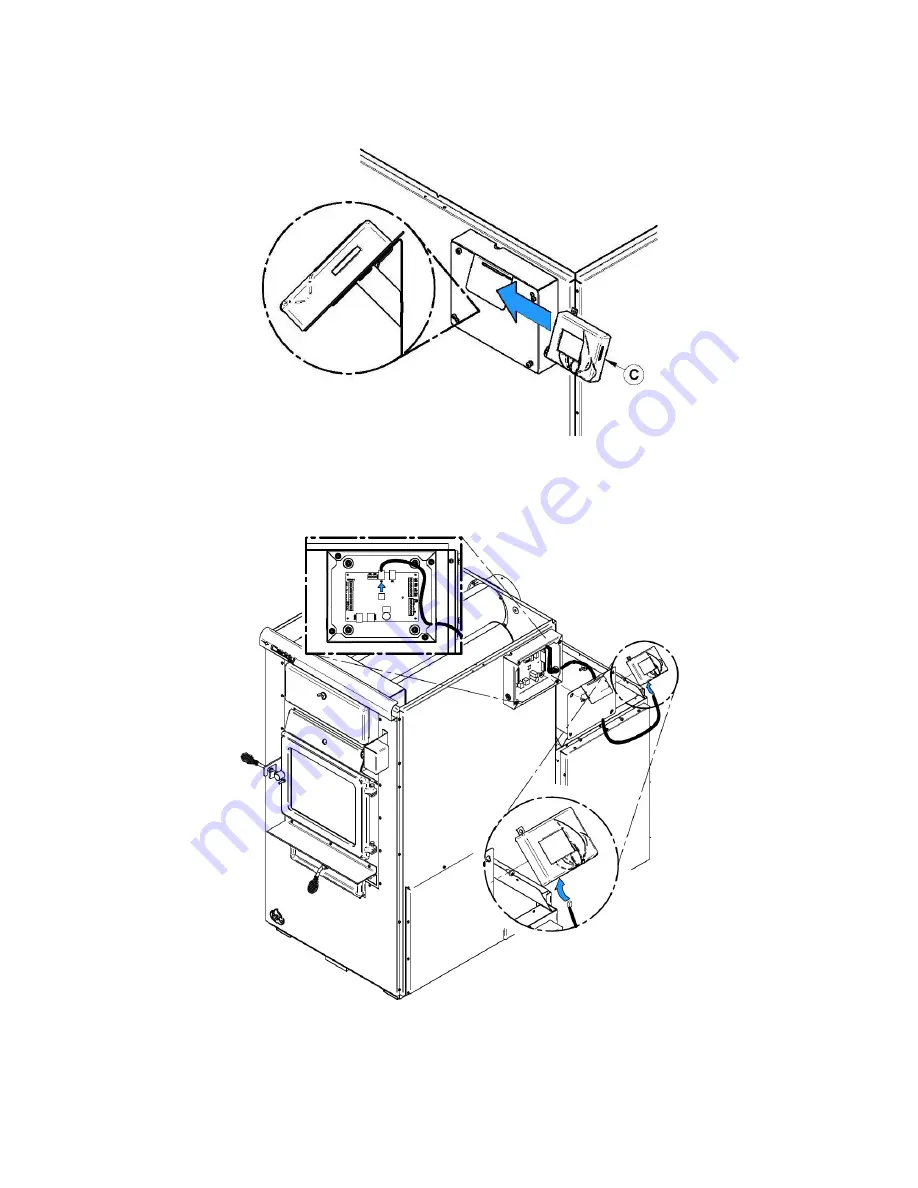

9.3. TOUCHSCREEN INSTALLATION AND CONNECTION

The touch screen is used to operate the system. It must be installed on the support provided at the back of the furnace,

on the same side as the link board housing.

Connect link board with the touch screen using the telecommunication wire provided with the user manual. Plug the

telecommunication wire in connector labeled LCD and pull it out of the board housing through the bottom grommet.

Simply run the wire on the side of the furnace. Replace the access panel of the link board. Note that the touch screen

is removable if access is restricted.

Summary of Contents for PF01302

Page 8: ...8 6 2 COMBINED WOOD ELECTRIC ...

Page 45: ...45 15 GENERAL ELECTRICAL DIAGRAM ...

Page 46: ...46 16 ELECTRICAL DIAGRAM FOR PARALLEL FURNACE ...

Page 47: ...47 17 ELECTRICAL DIAGRAM FOR ELECTRIC UNIT ...

Page 49: ...49 18 4 AIR CONDITIONNING DAMPER 18 5 HUMIDIFIER 18 6 HEAT PUMP ...

Page 50: ...50 19 EXPLODED VIEW AND PART LIST ...

Page 51: ...51 ...

Page 52: ...52 ...

Page 53: ...53 ...

Page 54: ...54 ...