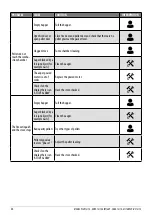

ATENA3 PLUS 12/14 - DUKE 12/14 AIRTIGHT - SABA 12/14 - MITHOS3 PLUS 12/14

20

5.12 REMOVAL OF SIDE PANELS (MITHOS3 PLUS 12/14)

5.13

To disassemble the side panels, proceed as follows:

• Remove the 2 screws of the side from the bottom of the panel (see

Fig. 45

).

• Unhook the side panel (see

Fig. 46

).

• To assemble, proceed in reverse order.

Fig. 45 - Screw removal

Fig. 46 - Removing the side panel

5.14 REAR OR UPPER FUME EXHAUST (ATENA

3

PLUS 12/14 - DUKE 12/14 AIRTIGHT - SABA 12/14)

The connection of the fume exhaust can be at the back or on top.

REAR EXHAUST

Fig. 47 - Connection of the fume exhaust

• Position the pipe as shown in

Fig. 47

.

UPPER EXHAUST

Fig. 48 - Remove the cap (Saba 14)

Fig. 49 - Remove the cap (Atena

3

Plus 12/14 -

Duke At)

Fig. 50 - Connect the Tee fitting