9

GRACE3 - SPIRIT3 - MADISON - TABLA - ROXY - ATRIUM - SOLO 5

LEGEND

Fig. 8

1

Insulating material

2

Inspection plug

3

Minimum safety distance = 0,5 mt

• External chimney flue entirely made up of insulated stainless steel pipes, i.e. with double wall of minimum Ø100/120 mm: all

must be firmly attached to the wall. For chimney against wind effects please (see

Fig. 4

).

• Ducting system through T-unions which enables an easy cleaning without disassembling the pipes.

We recommend to check with your chimney flue manufacturer the safety distances which must be respected

and the type of insulating material. The aforesaid regulations are valid also for holes made on the wall (EN

13501 - EN 13063 - EN 1856 - EN 1806 - EN 15827).

4

COMBUSTION AIR

4.1

EXTERNAL AIR INLET

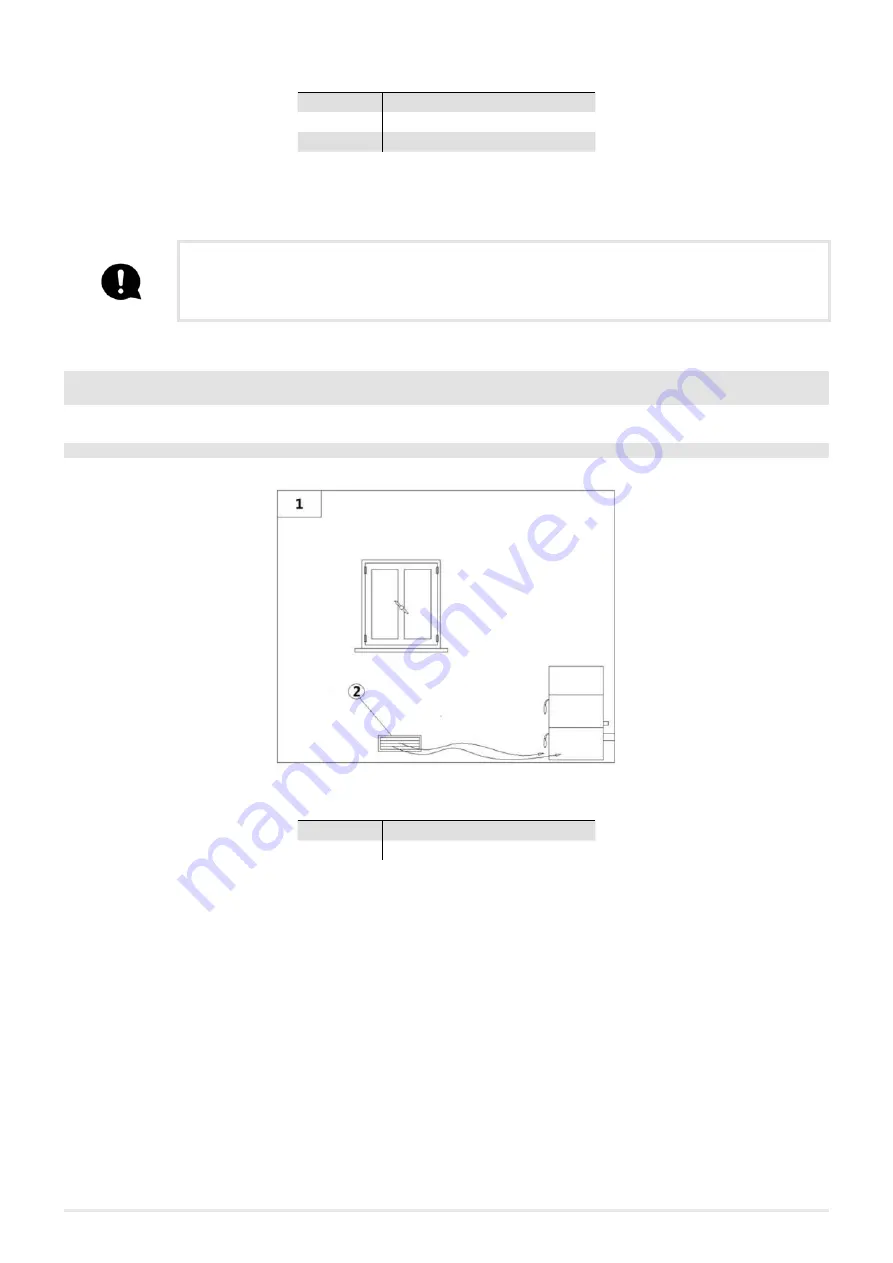

Fig. 9 - Direct air inflow

LEGEND

Fig. 9

1

Room to ventilate

2

External air inlet

• The room must be endowed with an external air recycling for a good climate in your ambient.

• The air inflow from outside to the inner occurs directly, through an opening on the external wall of the room (see

Fig. 9

).

• Bedrooms, garages, and store of flammable materials are excluded.

• The air inlet should have a total net surface of 80 sqcm

2

: the aforesaid surface is to widen if inside the room there are other

activated appliances (for example: electric ventilators for foul air suction, cooker hoods, other stoves, etc...) which depress the

environment.

• At switched on appliance it is necessary to check that the pressure fall between the room and the outside does not exceed 4,0

Pa value: if necessary widen the air inlet (EN 13384).

• The air inlet must be realized at a height close to the floor with an external grid against birds. In such a way it cannot be ob-

structed by any object.

•

In case of installation with sealed-chamber the air inlet is not necessary.