19

CRISTAL 9 - LIFE 9 - CRISTAL PLUS 9 - ICON PLUS 9 - STEEL 9

When one or more programmes are active, the panel alternately displays the boiler status and TIMER “n” whereby “n” is the number

relating to the activated timer programmes, separated from each other with a dash

Example:

• TIMER 1 Timer programme 1 active.

• TIMER 1-4 Timer programmes 1 and 4 active.

• TIMER 1-2-3-4-5-6 Timer programmes all active.

EXAMPLE OF PROGRAMMING

With boiler on or off:

• access the MENU,

• scroll to TIMER with the <> arrows,

• press the “Menu” key

• the system proposes “P1” (Press the <> keys for the subsequent timers P2,P3, P4, P5, P6)

• to activate “P1” press the “Menu” key

• press + - and select “ON”

• confirm with the “Menu” key

At this point it will propose 00:00 as starting time, with key + - adjust the starting time and press the “menu” key to confirm.

The next step proposes a shutdown time of 10 minutes above that set for start-up: press the + key and adjust the shutdown time,

confirm with the “menu” key.

Subsequently the system proposes the days of the week in which to activate or deactivate the previously set timer. With the - or +

key highlight with the white background the day in which one wishes to activate the timer and confirm with the “menu” key. If no

day of the week is confirmed as active, in turn the timer programme will not appear active in the status screen.

Continue to program the following days or press “ESC” to exit. Repeat the procedure to program the other timers.

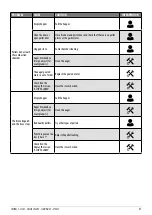

8.12 PROGRAMMING EXAMPLES:

P1

P2

on

off

day

on

off

day

08:00

12:00

mon

11:00

14:00

mon

Boiler on from 08:00 to 14:00

on

off

day

on

off

day

08:00

11:00

mon

11:00

14:00

mon

Boiler on from 08:00 to 14:00

on

off

day

on

off

day

17:00

24:00

mon

00:00

06:00

tue

Boiler on from 17:00 on monday to 06:00 on tuesday

8.13 NOTES FOR TIMER OPERATION

• Start-up with the timer always takes place with the last temperature and ventilation settings (or with default 20°C and V3

settings in the event they have never been changed).

• It is possible to set the shutdown time from “ignition time + 10 minutes” up to 23:50. If 24:00 is set as shutdown time, the stove

will not switch off (use this shutdown time, for example, when the next day is programmed to continue from 00:00).

• If the shutdown time is not already memorised, it proposes a start-up time in + 10 minutes.

• A timer programme switches the boiler off at 24:00 of one day and another programme switches it on at 00:00 of the next day:

the boiler stays on.

• A programme proposes a start-up and shutdown in times included within another timer programme: if the boiler is already on,

start will not have any effect, while OFF will switch it off.

• In the boiler on and timer active condition, press the OFF key and the boiler will switch off, it will switch on automatically at

the next time set on the timer.

• In the boiler off and timer active condition, press the ON key and the boiler will switch on, it will switch off at the time set on

the active timer.

8.14 AUTO ECO MODE (SEE SECTION F-G SETTINGS MENU A PAG. 14)

To activate the “Auto-Eco” mode and adjust the time refer

SETTINGS MENU a pag. 14

.

The possibility to adjust the “

t Off Time Eco

” comes from the need to ensure proper operation in the various rooms the boiler can

be installed in and prevent continuous shutdowns and start-ups in the event the temperature is subject to sudden changes (air

currents, poorly insulated rooms, etc.).

Summary of Contents for CRISTAL 9

Page 35: ...NOTE ...