13

vEGA - sIRE

3

pLUs - DoGE

3

pLUs - sFERA

3

- sFERA

3

pLUs - pRINCE

3

- pRINCE

3

pLUs - GLoBE - tREND - ELIsE

3

pLUs

EN

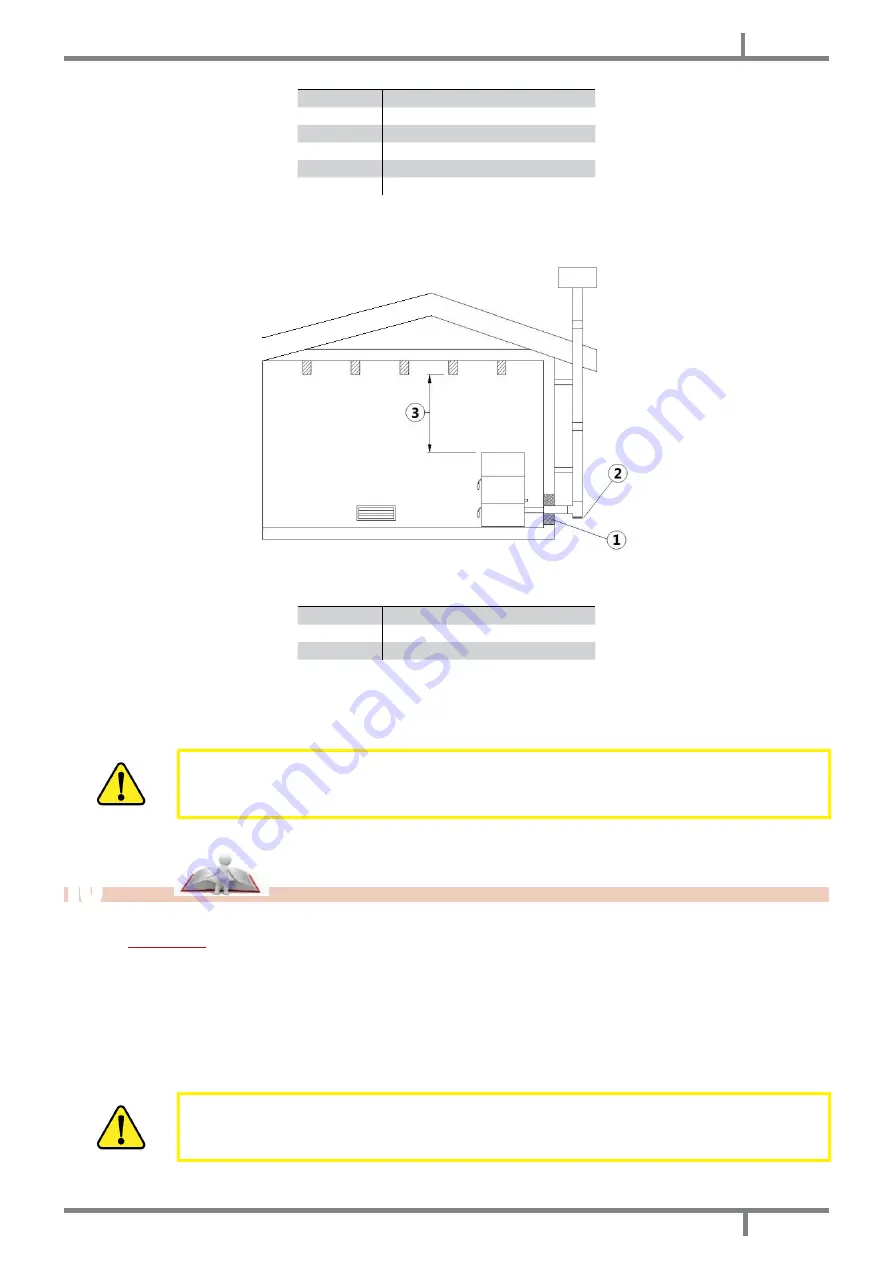

LEGEND

1

Insulating material

2

Inspection plug

3

Chimney inspection entrance

4

Minimum safety distance = 0,5 mt

5

Inclination ≥ 3°

6

Level section ≤ 1 mt

• Old chimney flue with an inserted pipe of minimum Ø100/120 mm and with an external door which enables

the chimney cleaning.

Fig. 14 - Example 3

LEGEND

1

Insulating material

2

Inspection plug

3

Minimum safety distance = 0,5 mt

• External chimney flue entirely made up of insulated stainless steel pipes, i.e. with double wall of minimum

Ø100/120 mm: all must be firmly attached to the wall. For chimney against wind effects please (see

).

• Ducting system through T-unions which enables an easy cleaning without disassembling the pipes.

We recommend to check with your chimney flue manufacturer the safety distances which

must be respected and the type of insulating material. The aforesaid regulations are valid

also for holes made on the wall (EN 13501 - EN 13063 - EN 1856 - EN 1806 - EN 15827).

10

FUEL

10.1

FUEL

• Use top-quality pellets because they have influence in the calorific value and in ash remains.

• Pellets features are: dimension Ø6-7mm (D06 Class), maximum lenght 40 mm, calorific value 5kWh/kg, humidity

≤ 10%, ash remains ≤ 0,7%, they must be correctly pressed and not much mealy, without sizing agents, resins

and other additives (it is advisable to use pellets in compliance with the regulation EN14961-2 type ENplus-A1

).

• Not adequate pellets cause a bad combustion, a frequent burning pot obstruction and exhaust conduits

obstruction. Further it decreases the calorific value, soils the glass and increases consumptions and ash and

unburnt granules quantity.

Humid pellets cause a bad combustion and running, so please assure you that they are

stored in dry places and far at least one meter from the stove and/or any other source of

heat.

• It is advisable to try different type of pellets available on the market and to choose that which gives the best

Summary of Contents for DOGE3 PLUS

Page 47: ...NOTE ...