25

vEGA - sIRE

3

pLUs - DoGE

3

pLUs - sFERA

3

- sFERA

3

pLUs - pRINCE

3

- pRINCE

3

pLUs - GLoBE - tREND - ELIsE

3

pLUs

EN

• If the stove is not fitted with ducting system, it provide a hot air capacity ranging from a minimum of 61 m

3

/h

to a maximum of 130 m

3

/h with a temperature ranging between 90°C and 136°C.

• For the ducting system, we recommend using a pipe with a maximum length of 6 mt and up to three 90°

elbows in order to maintain hot air temperature.

• Use pipes with smooth internal surface and a diameter of 80 mm.

• Fit the pipe with insulating material if it passes through a cold wall.

• The outlet must be protected by a grid with wide mesh and a minimum total surface area of 40 cm

2

.

• If the pipes used are longer than 6 mt, the air capacity ranges from a minimum of 58 m

3

/h to a maximum of

883 m

3

/h and the temperature from 65°C to 99°C. (These values refer to the laboratory used for the tests. The

room where the stove is installed may register different values both in terms of capacity and temperature).

• If you wish to increase air capacity, install at the end of the pipe a small wall-mounted fan with a capacity

exceeding 130 m

3

/h. The installation must be carried out by an authorised technician.

• According to the factory parameters, 1/2 of the generated heat is conveyed into the room where the stove

is installed, while the remaining 1/2 are conveyed through the left ducting pipe system.

• Balance heat output with air capacity to obtain the best performance (see

The operation above must be carried out by an authorised technician.

11.13

UsING tHE stovE WItHoUt DUCtING

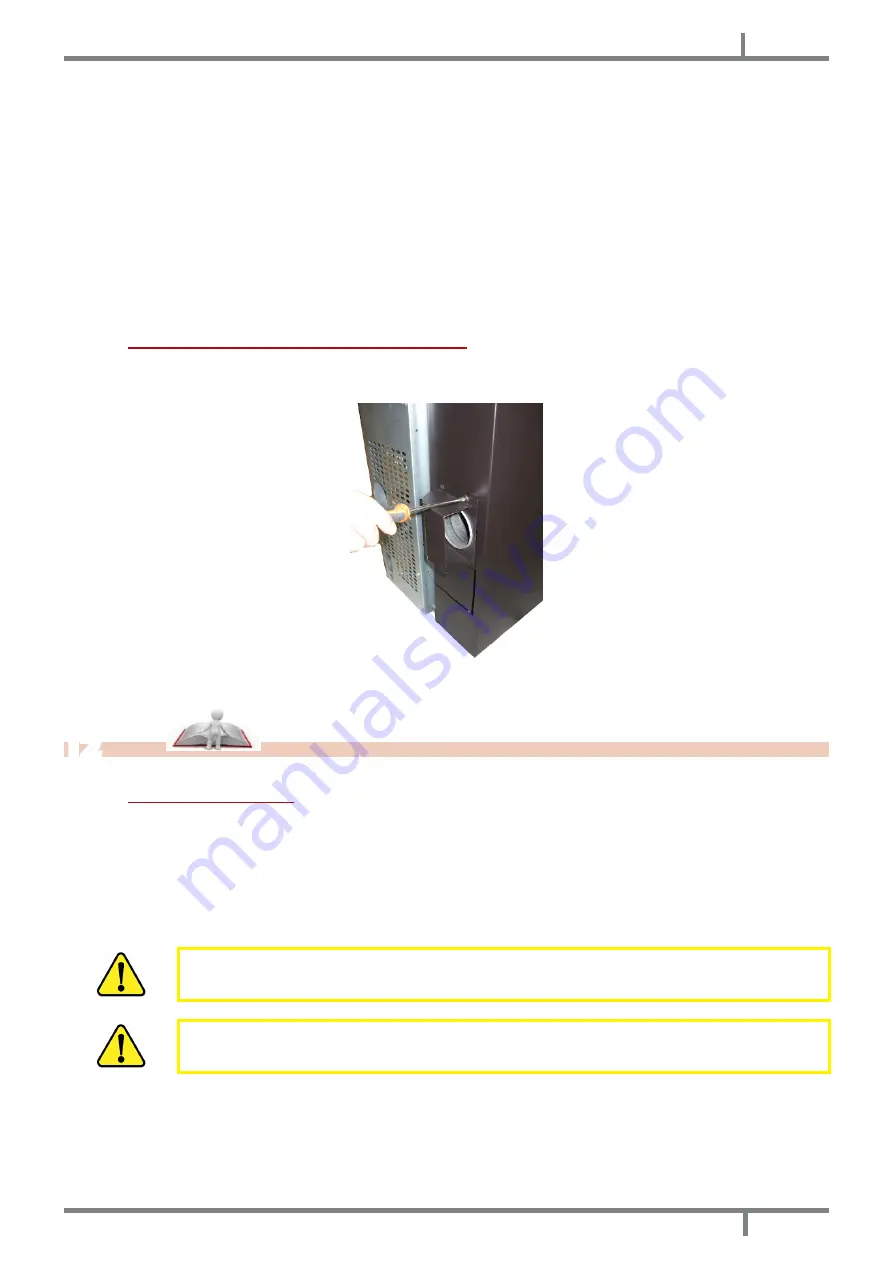

The stove can be used without ducting the air to other environments.

In this case, assemble the environment diffuser in the stove's rear (see

).

Fig. 50 - Diffuser assembly

12

UsE

12.1

INtRoDUCtIoN

To have the best performance with the lowest consumption please follow the here descripted instructions.

• The lightning of the pellets occurs very easily if the installation is correct and if the chimney flue is efficient.

• Switch on the stove at Power 1 for at least 2 hours in order to enable the materials which make up the boiler

and the fireplace to adjust the inner springing stress.

• By using the stove the varnish inside the combustion chamber could be subjected to alterations. This

occurrence can be attributed to different reasons: an excessive stove overheating, the presence of chemical

agents in bad quality pellets, bad chimney draught, etc. Therefore varnish endurance in the combustion

chamber cannot be guarantee.

Oily plant waste and lacquers can cause smells and smoke during the first working hours: it

is advisable to ventilate the room because they could be noxious to people and animals.

Set values from 1 to 5 are defined by the manufacturer and they can be changed only by

an authorized technician.

Summary of Contents for DOGE3 PLUS

Page 47: ...NOTE ...