17

EASY - SWEET

3

EN

11.5

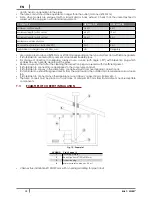

SWEET SIDE PANEL DISASSEMBLY

For this model there is NO need to remove the frame to disassemble the side panels.

To access the internal stove parts, disassemble the side panels as indicated below:

•

Loosen the 3 back screws (see

Fig. 21 page 17

).

•

Turn the side panel outwards (see

Fig. 22 page 17

).

•

Disengage the front teeth and remove the side panel (see

Fig. 23 page 17

).

•

To assemble proceed in reverse order.

Fig. 21 - Loosen screws

Fig. 22 - Rotate side panels

Fig. 23 - Remove side panels

11.6

SWEET FRAME DISASSEMBLY

Proceed as follows to disassemble the frame:

Fig. 24 - Remove screws

Fig. 25 - Unhook frame

•

Remove the 2 screws at the bottom of the frame (see

Fig. 24 page 17

).

•

Unhook the frame by pushing it upwards and remove it (see

Fig. 25 page 17

).

•

To assemble proceed in reverse order.

11.7

ELECTRIC CONNECTION

Warning: the appliance must be installed by an authorized technician!

•

The electric connection occurs through a cable with plug put in an electric socket which is able to support

charge and tension specific of every model, as described in the technical datas table (see

page 36

).

Summary of Contents for EASY-SWEET 3

Page 38: ...NOTE ...

Page 39: ...NOTE ...