IDRO PRINCE

3

12-16-23-23 H

2

O - IDRO PRINCE 30-30 H

2

O - AQUOS

3

16-23-23 H

2

O - IDRON 16-22 AIRTIGHT - MIRA 16-22 - TESIS 16-23 AIRTIGHT - HIDROFIRE 22.8

40

8

ELECTRICAL CONNECTION

8.1

ELECTRICALLY CONNECTING THE STOVE

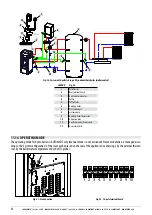

Connect the power cable first to the back of the stove, then to a wall plug.

Only use the main switch to turn on the stove; otherwise, it is a good idea to keep it off.

When the stove is not in use, it is advisable to unplug the power cable.

Fig. 48 - Electrically connecting the stove

8.2

STOVE POWER SUPPLY

Once the power cable is connected to the back of the stove, move the switch (also located on the back) to the (I) position.

The illuminated button of the switch will come on.

The switch on the back of the stove is used to power the system.

There is a fuse holder compartment on the back of the stove, under the power plug. Use a screwdriver to open the fuse holder

compartment cover and, if necessary, replace the fuses (3.15 A time delay).

Fig. 49 - Switch

LEGEND

A

Stove power supply

B

Stove On/Off switch

C

Fuse holder compartment